A variable temperature variable pressure diffusion process for improving photoelectric conversion efficiency

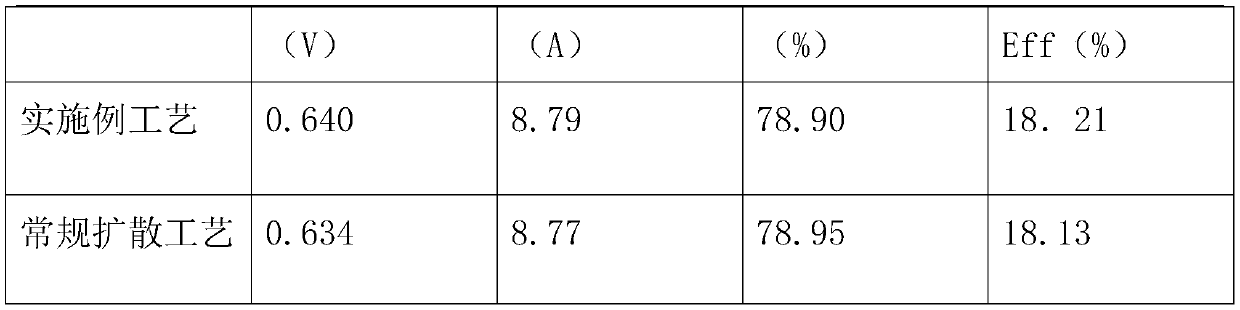

A technology of photoelectric conversion efficiency and diffusion process, applied in the field of solar cell diffusion process, can solve the problems of inability to guarantee intra-chip and inter-chip uniformity, increase the proportion of defective films, reduce the total flow and total time of small nitrogen, and achieve improved The effect of battery yield and photoelectric conversion efficiency of battery, reduction of phosphorus source consumption, and reduction of spacing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

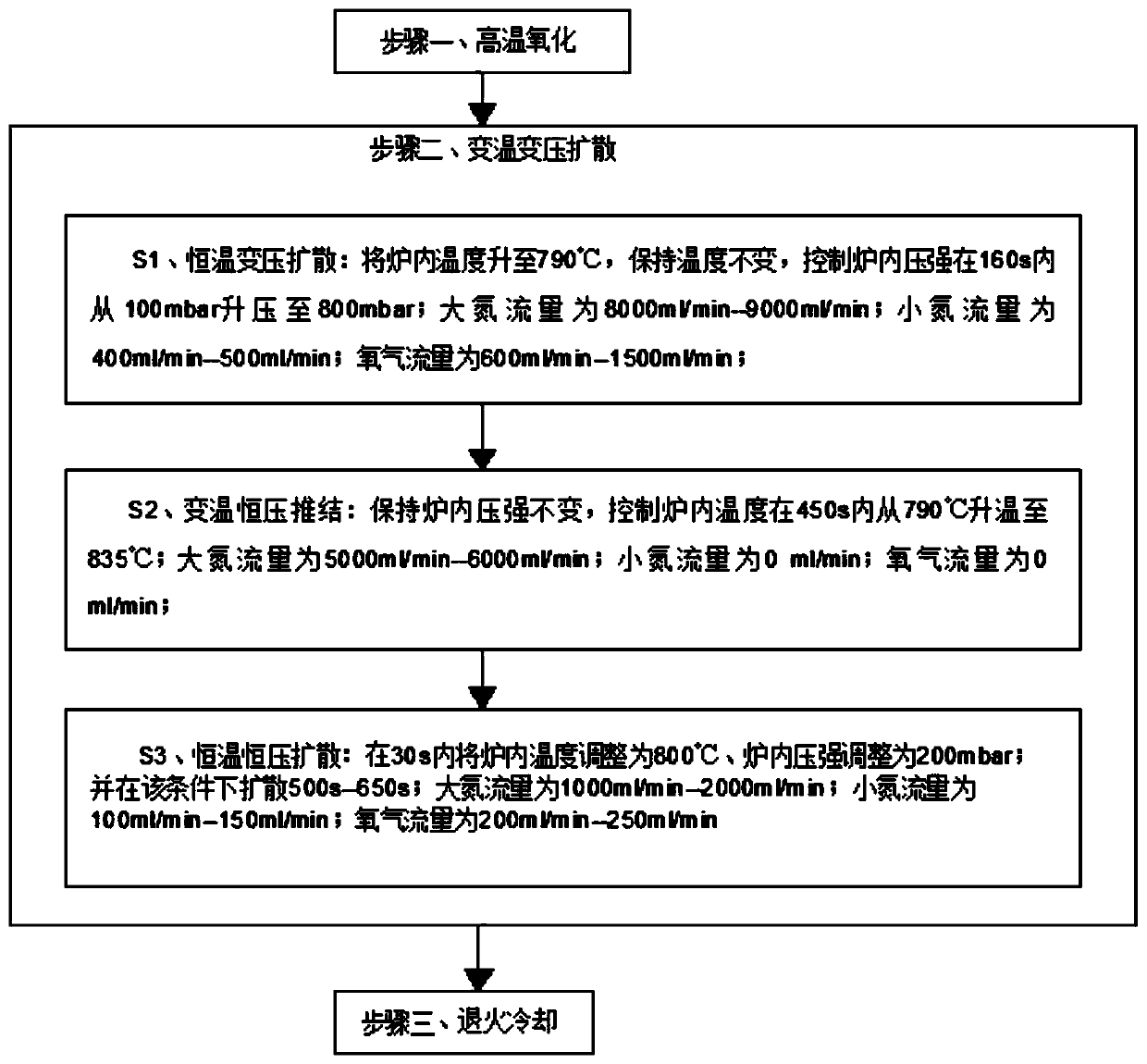

[0035] A variable temperature variable pressure diffusion process for improving photoelectric conversion efficiency, comprising the following steps:

[0036] Step 1. High-temperature oxidation: After putting the silicon wafer into the diffusion furnace, set the pressure in the furnace to 100mbar and the temperature to 780°C, and oxidize the silicon wafer for 100s;

[0037] Step 2. Variable temperature and variable pressure diffusion: Diffusion is carried out by step-by-step diffusion method, and the specific steps are as follows:

[0038] S1. Constant temperature variable pressure diffusion: raise the temperature in the furnace to 790°C, keep the temperature constant, control the pressure in the furnace to increase from 100mbar to 800mbar within 160s; the maximum nitrogen flow rate is 8000ml / min; the small nitrogen flow rate is 400ml / min ;Oxygen flow rate is 600ml / min;

[0039] S2. Variable temperature and constant pressure pushing knot: keep the pressure in the furnace const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com