Waterproof insulation board

A technology of thermal insulation board and Portland cement, which is applied in the field of building materials, can solve the problems of poor thermal insulation performance and waterproof performance of thermal insulation boards, and achieve the effects of good thermal insulation performance, excellent waterproof performance and improved thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

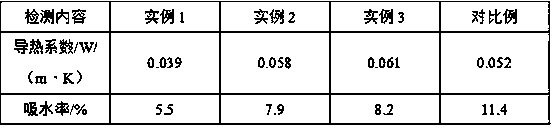

Examples

example 1

[0030]Pulverize the zeolite and pass it through a 150-mesh sieve to obtain a refined zeolite. After calcining the refined zeolite at a temperature of 600°C for 8 hours, a pretreated zeolite is obtained. Mix the block copolymer with 18% hydrochloric acid by mass Mix at a ratio of 1:55. Stir and mix for 8 hours at a temperature of 55°C and a rotational speed of 350r / min to obtain a pretreatment solution. Mix the pretreatment solution and mesitylene at a mass ratio of 160:1, and mix at a temperature of Under the conditions of 55°C and a rotating speed of 280r / min, after stirring and mixing for 80min, add tetraethyl orthosilicate 0.15 times the mass of the pretreatment liquid to the mixture of the pretreatment liquid and mesitylene. After stirring and mixing under the condition of 240r / min for 28 hours, the mixed solution was obtained. After the mixed solution was aged at room temperature for 15 hours, the filter cake was obtained by suction filtration, and the filter cake was wash...

example 2

[0032] Pulverize the zeolite and pass through a 150-mesh sieve to obtain a refined zeolite. After calcining the refined zeolite at a temperature of 600°C for 8 hours, a pretreated zeolite is obtained. Mix expanded perlite and silicone emulsion at a mass ratio of 1:8 Put it in a vacuum cylinder, and after evacuating for 55 minutes, filter to obtain modified expanded perlite; mix the pretreated zeolite with 15% hydrochloric acid at a mass ratio of 1:10, soak at room temperature for 2 hours, and filter to obtain To acidify zeolite, mix acidified zeolite and water in a conical flask at a mass ratio of 1:10, and add 0.3 times the mass of acidified zeolite to the conical flask. 0.2 times of calcium nitrate, stirred and mixed for 40 minutes at a temperature of 35°C and a speed of 350r / min to obtain an additive blank, which was left to stand for 8 hours at a temperature of 38°C, and then placed at a temperature of 65 ℃, the rotation speed is 180r / min, the pressure is 600KPa, rotary st...

example 3

[0034] Pulverize the zeolite and pass it through a 150-mesh sieve to obtain a refined zeolite. After calcining the refined zeolite at a temperature of 600°C for 8 hours, a pretreated zeolite is obtained. Mix the block copolymer with 18% hydrochloric acid by mass Mix at a ratio of 1:55. Stir and mix for 8 hours at a temperature of 55°C and a rotational speed of 350r / min to obtain a pretreatment solution. Mix the pretreatment solution and mesitylene at a mass ratio of 160:1, and mix at a temperature of Under the conditions of 55°C and a rotating speed of 280r / min, after stirring and mixing for 80min, add tetraethyl orthosilicate 0.15 times the mass of the pretreatment liquid to the mixture of the pretreatment liquid and mesitylene. After stirring and mixing under the condition of 240r / min for 28 hours, the mixed solution was obtained. After the mixed solution was aged at room temperature for 15 hours, the filter cake was obtained by suction filtration, and the filter cake was was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com