Method of producing pharmaceutical grade sodium hyaluronate from phytone

A technology of sodium hyaluronate and plant peptone, which is applied in the field of biological fermentation, can solve the problems of excessive endotoxin content, few sources of raw materials, and unstable quality, and achieve the effects of small nucleic acid content, avoiding the risk of germs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

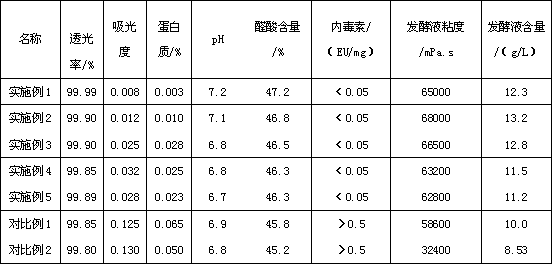

Examples

Embodiment 1

[0040] In this example, the method for producing pharmaceutical-grade sodium hyaluronate using plant peptone includes a) using vegetable protein as a raw material to prepare a fermentation medium, b) using the prepared fermentation medium to prepare sodium hyaluronate by microbial fermentation,

[0041] 1. The preparation of fermentation medium comprises the steps:

[0042] (1) Dissolve the material in the dissolving tank, add 800L of water, start stirring, open the steam valve until the temperature rises to 75°C, close the steam valve, put 125kg of zein into the dissolving tank, and then open the steam valve to maintain the temperature of the material at 95°C and dissolve for 10 minutes ;

[0043] (2) Enzymolysis After the dissolution is completed, turn on the cold water and lower the temperature to 50°C, adjust the pH of the material to 8.5 with alkali, then add 0.8kg of protease for enzymolysis for 5 hours, and continue to add alkali during the enzymolysis to keep the pH at...

Embodiment 2

[0067] In this example, the method for producing pharmaceutical-grade sodium hyaluronate using plant peptone includes a) using vegetable protein as a raw material to prepare a fermentation medium, and b) using the prepared fermentation medium to prepare sodium hyaluronate by microbial fermentation. The preparation of fermentation medium comprises the steps:

[0068] (1) Dissolve the material in the dissolution tank, add 800L of water, start stirring, open the steam valve until the temperature rises to 90°C, close the steam valve, put 125kg of soybean protein into the dissolution tank, and then open the steam valve to maintain the temperature of the material at 100°C and dissolve for 30 minutes ;

[0069] (2) Enzymolysis After the dissolution is completed, turn on the cold water and lower the temperature to 40°C, adjust the pH of the material to 7 with alkali, then add 0.8kg of protease for enzymolysis for 10 hours, and keep adding alkali during the enzymolysis to keep the pH a...

Embodiment 3

[0077] In this example, the method for producing pharmaceutical-grade sodium hyaluronate using plant peptone includes a) using vegetable protein as a raw material to prepare a fermentation medium, and b) using the prepared fermentation medium to prepare sodium hyaluronate by microbial fermentation. The preparation of fermentation medium comprises the steps:

[0078] (1) Dissolve the material in the dissolution tank, add 800L of water, start stirring, open the steam valve until the temperature rises to 85°C, close the steam valve, put 125kg of wheat gluten flour into the dissolution tank, and then open the steam valve to maintain the temperature of the material at 95°C for dissolution 1h;

[0079] (2) Enzymatic hydrolysis After the dissolution is completed, turn on cold water and lower the temperature to 60°C, adjust the pH of the material to 10 with alkali, then add 0.8kg of protease for enzymatic hydrolysis for 1 hour, and continue to add alkali during the enzymatic hydrolysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com