Buffer system for impact ground pressure resisting of hydraulic support, and application thereof

A technology of buffer system and hydraulic support, which is applied in pillars/supports, mining equipment, earthwork drilling and mining, etc. It can solve the problems of increasing the complexity of manufacturing process and production cost, the failure of large flow safety valve to respond in time, and the failure of active adjustment and response of supports and other problems, to achieve the effect of ensuring safe and effective work, stable buffering process, and convenient replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

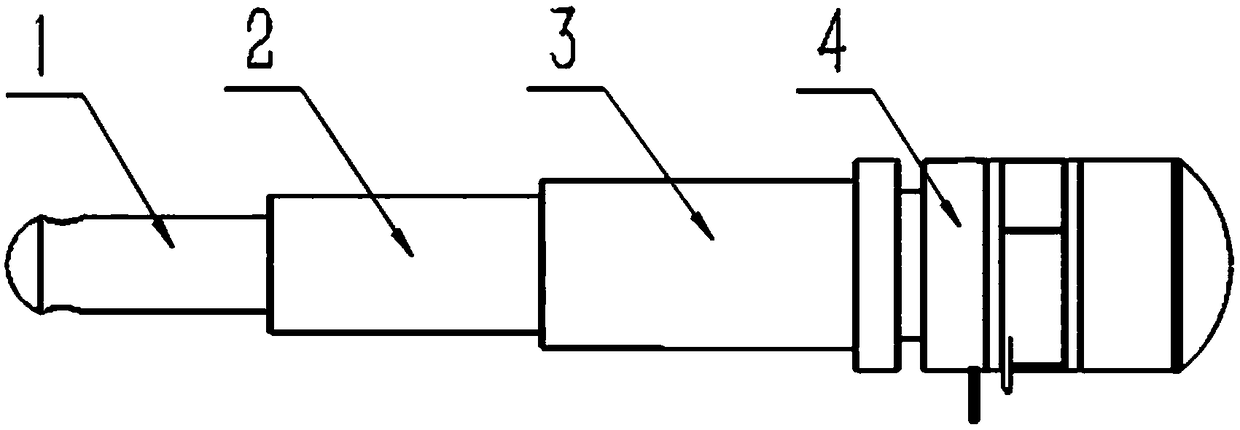

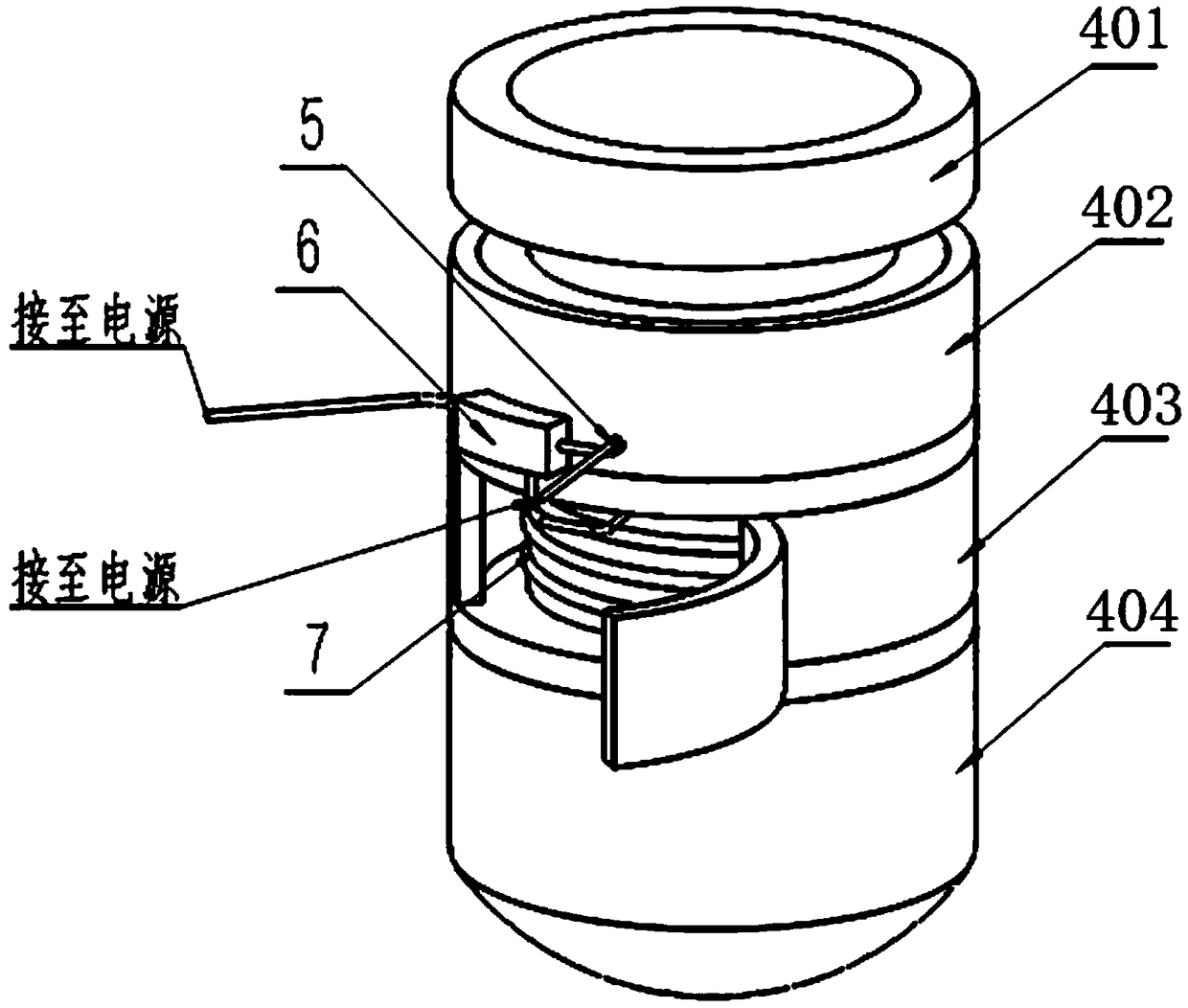

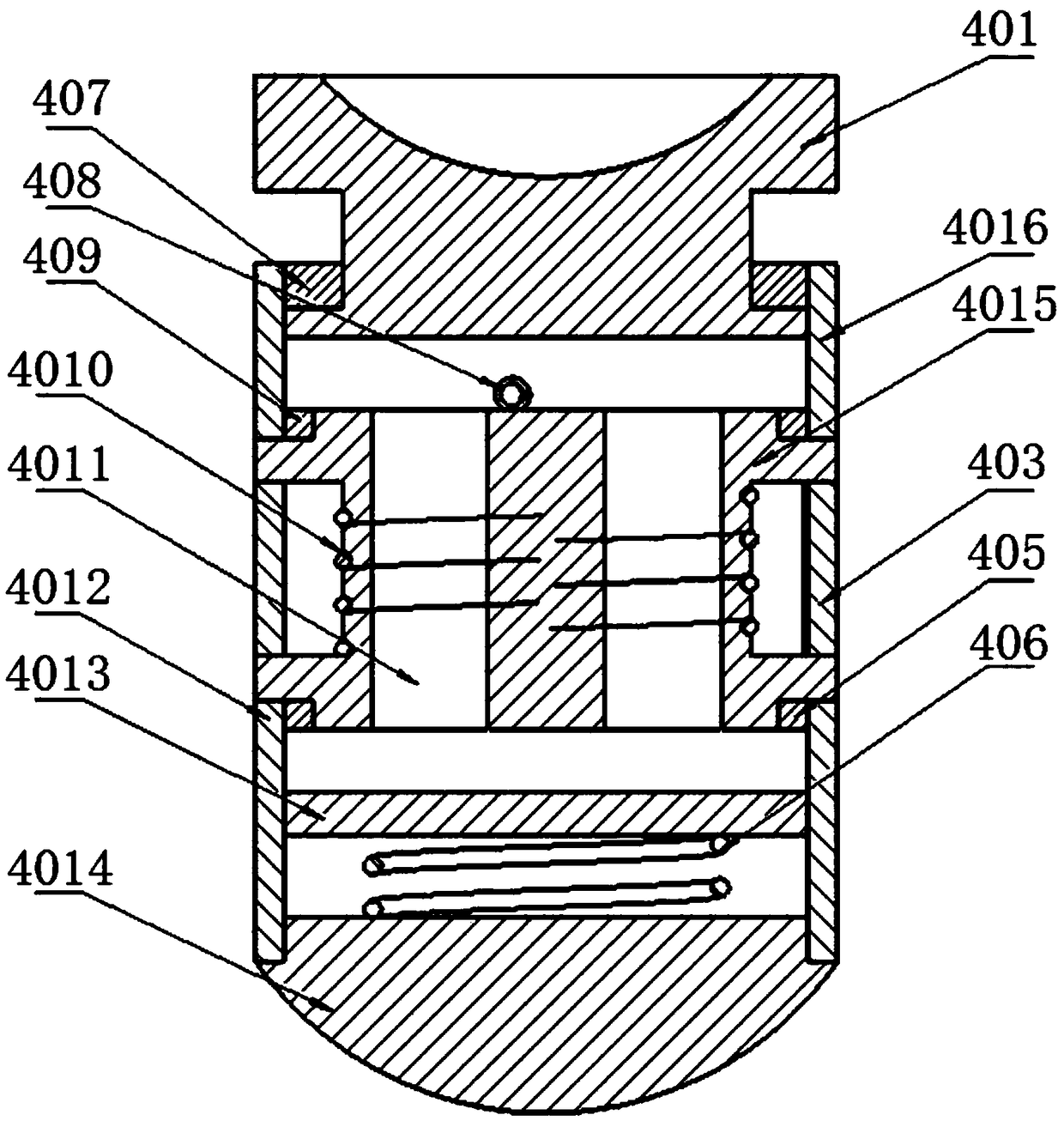

[0043] Such as Figure 1 to Figure 6As shown, this embodiment provides a buffer system for hydraulic supports against shock ground pressure. The buffer system mainly includes an improved column, and the column includes a live column 1, a middle cylinder 2, and a bottom cylinder 3 sequentially connected from top to bottom. And anti-shock buffer 4, anti-shock buffer 4 is provided with connected pressure sensor 5 and controller 6, and controller 6 is also electrically connected with the magneto-rheological coil in the anti-shock buffer 4; The pressure information is adjusted in real time by the controller 6 and the current of the magneto-rheological coil is switched on and off, so that the anti-shock buffer 4 assists in buffering the impact ground pressure received by the column.

[0044] The technical solution provided in this embodiment, in the traditional way of only relying on the large-flow safety valve to buffer the impact ground pressure of the column, by adding an intelli...

Embodiment 2

[0071] A hydraulic support, including a top beam, a base and the buffer system described in Embodiment 1, the improved column of Embodiment 1 is installed between the top beam and the base, the live column 1 is connected with the top beam, and the shock-resistant buffer The base 4014 is connected with the base of the hydraulic support.

Embodiment 3

[0073] As the working method of the buffer system for hydraulic support anti-shock rock pressure as described in embodiment 1, the specific working process includes the following steps:

[0074] (1) Install the column in the buffer system of Embodiment 1 instead of the traditional column on the hydraulic support, wherein the live column 1 is connected to the top beam, the base 4014 of the shock-resistant buffer is connected to the base of the hydraulic support, the pressure sensor 5 and the controller 6 are also respectively connected to an external power supply;

[0075] (2) When the impact ground pressure occurs on the roof of the hydraulic support and the column is subjected to impact load, the support top beam moves down, the pressure sensor 5 collects the pressure signal and transmits it to the controller 6, and the controller 6 adjusts and switches the magneto-rheological coil in real time The current makes the anti-shock buffer generate damping force, which works before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com