N-type SnSe thermoelectric material and preparation method thereof

A thermoelectric material, N-type technology, applied in thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, chemical instruments and methods, etc., can solve problems such as hindering electron transmission, reducing electrical conductivity, etc., and achieve electrical performance improvement , The effect of improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a preparation method of the N-type SnSe thermoelectric material, comprising the following steps:

[0027] Mixing Sn, Se and SnBr to obtain a mixed material, the atomic molar ratio of Sn, Se and Br in the mixed material is 1:0.97~0.99:0.01~0.03;

[0028] The mixed material is synthesized according to a vertical gradient single temperature zone cooling method to synthesize an N-type SnSe thermoelectric material.

[0029] The present invention mixes Sn, Se and SnBr to obtain a mixed material, and the atomic molar ratio of Sn, Se and Br in the mixed material is 1:0.97-0.99:0.01-0.03.

[0030] In the present invention, the mass purity of the Sn and Se is independently preferably greater than 99.99%, and the SnBr 2 The mass purity is preferably greater than 99%.

[0031] In the present invention, the atomic molar ratio of Sn, Se and Br in the mixed material is preferably 1:0.98:0.02. In the preparation process of the present invention, t...

Embodiment 1

[0048] Sn and Se blocks with a purity greater than 99.99% and SnBr with a purity greater than 99% 2 The mixed material is obtained by mixing the atomic molar ratio of Sn, Se and Br in a ratio of 1:0.97:0.03;

[0049] The mixed material is synthesized according to a vertical gradient single temperature zone cooling method to synthesize an N-type SnSe thermoelectric material.

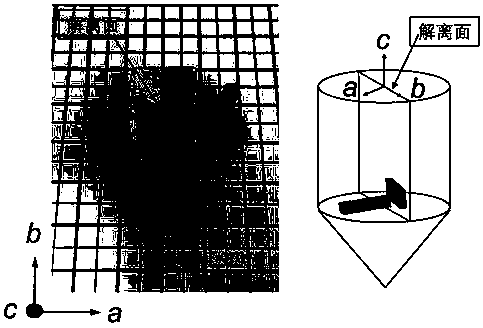

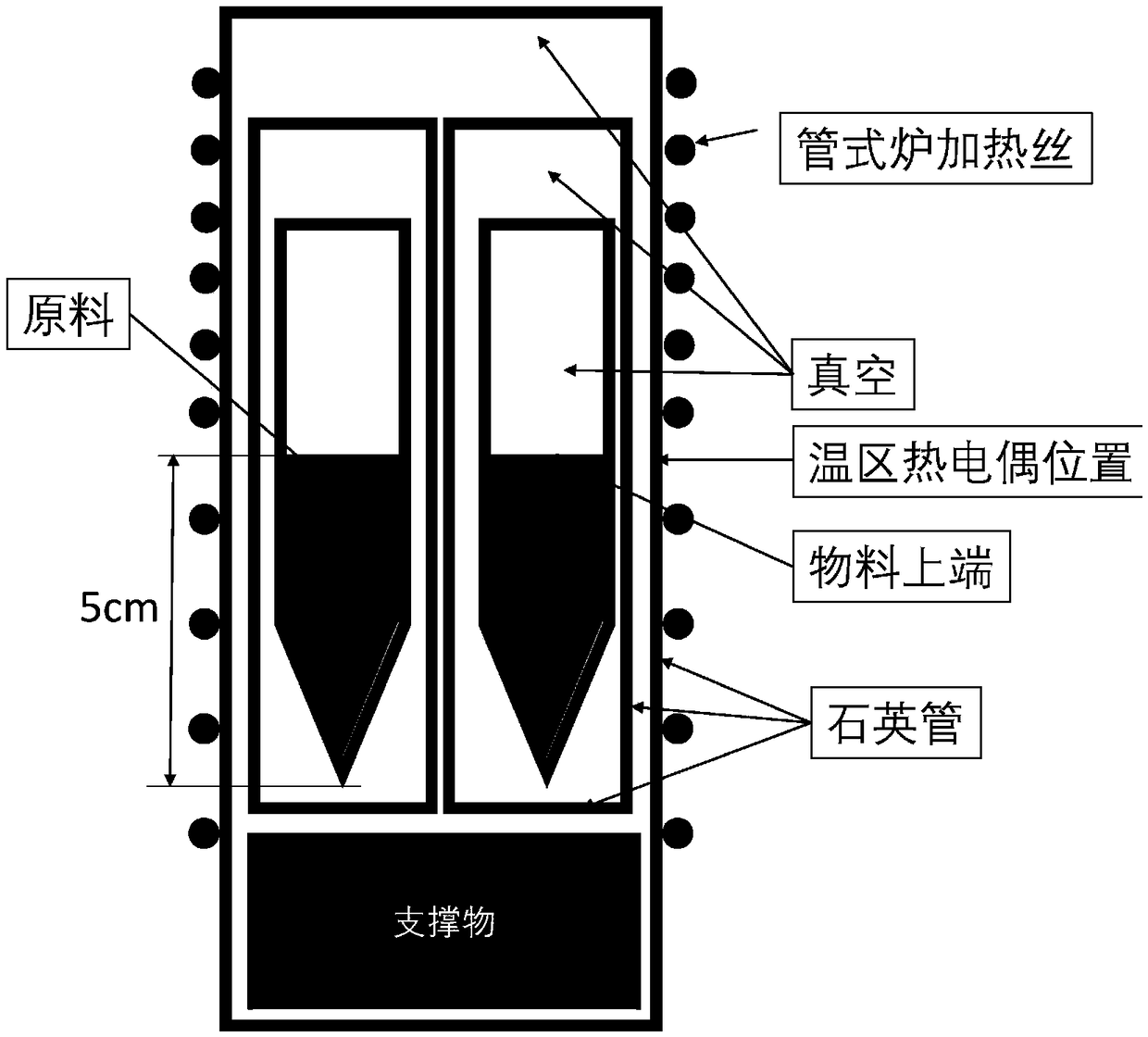

[0050] The vertical gradient single temperature zone cooling method specifically includes the following steps:

[0051] 1) Put the above-mentioned mixed material into a small quartz tube (5mm in diameter) with a tapered front end, and evacuate the small quartz tube containing the mixed material until the vacuum degree is less than 10 -2 Pa, filled with argon, and then evacuated to a vacuum degree of less than 10 -3 Pa, a small quartz tube sealed with a flame;

[0052] 2) Place the small quartz tube obtained in step 1) in a large quartz tube with a diameter greater than 5 mm, and carry out secondary vac...

Embodiment 2~5

[0057] The atomic molar ratios of Sn, Se and Br in Examples 2 to 5 are 1:0.975:0.025, 1:0.98:0.02, 1:0.985:0.015 and 1:0.99:0.01 respectively, and the conditions in Example 1 of the remaining steps are the same . Table 1 shows the carrier concentration and the highest ZT value in Examples 1-5.

[0058] Carrier concentration and the highest ZT value in Table 1 embodiment 1~5

[0059]

[0060]

[0061] It can be seen from Table 1 that the atomic molar ratio of Sn, Se and Br in the mixed material is 1:0.97~0.99:0.01~0.03, that is, the molar percentage of the Br component varies from 1% to 3%, and the carrier concentration of the material varies from 8.3 E18~1.21E19cm -3 , and it is an electron, indicating that the prepared material is an N-type semiconductor material. The carrier fluctuation directly affects the final performance value ZT value. The range of ZT value is 2.5-2.8, and the change value is 0.3. The ZT value of all examples is much higher than that of N-type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com