Flavor-enhancing umami tripeptide and derivatives and application thereof

A technology of derivatives and amino acids, which is applied in the field of tripeptide and its derivatives, to achieve the effect of improving meat taste and savory taste, and improving umami taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The solid-phase synthesis method synthesizes Ser-Phe-Glu polypeptide, comprises the following steps:

[0044] Swell and wash 1 g of dichloro resin, remove the Fmoc protecting group, add amino acid for condensation reaction, repeat the deprotection-condensation process until all amino acids are connected. Cut the resin to obtain the crude peptide Ser-Phe-Glu. Purified by reversed-phase high-performance liquid chromatography to obtain pure polypeptide.

Embodiment 2

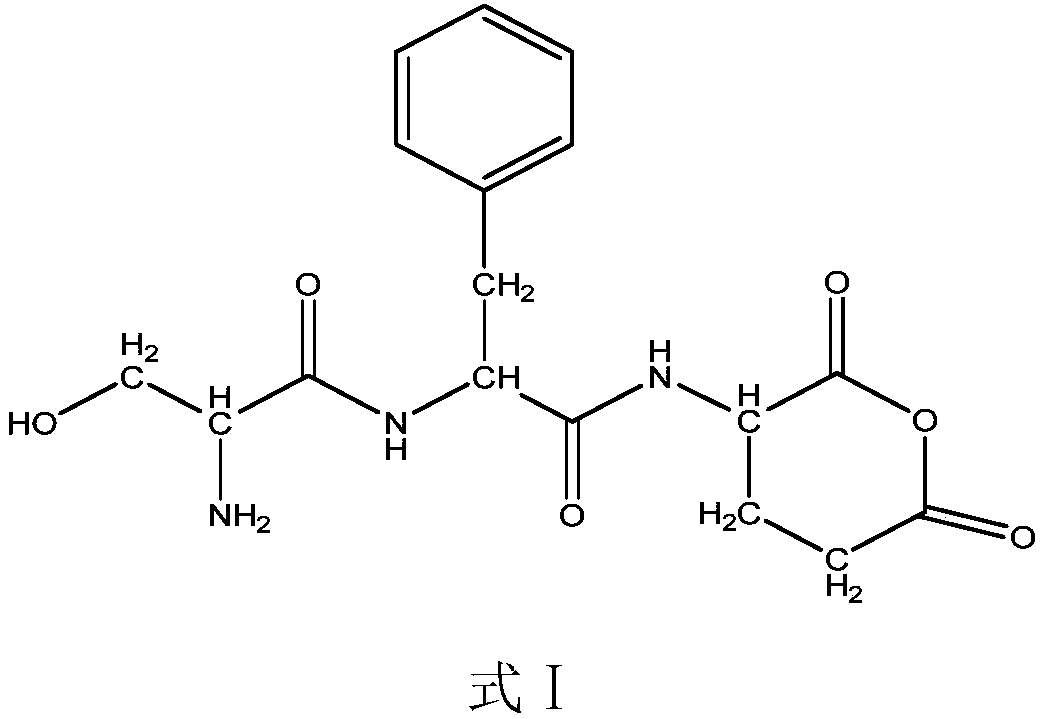

[0046] The preparation method of polypeptide Ser-Phe-Glu derivative (formula I), comprises the following steps:

[0047] The N-terminal of Glu is protected by a common protecting group (such as benzyloxyformyl), and a catalyst is added to promote the dehydration and condensation of the C-terminal carboxyl group of Glu and the side-chain carboxyl group to form a ring, and then the protecting group is removed to obtain the dehydrated compound of Glu. Then synthesize the polypeptide derivative I by solid-phase synthesis, swell and wash 1g of dichloro resin, remove the Fmoc protecting group, add the dehydration compound of amino acid and Glu to carry out condensation reaction, repeat the deprotection-condensation process until all the compounds are connected . The resin was cleaved to obtain the crude product of polypeptide derivative I. Purified by reverse-phase high-performance liquid chromatography to obtain pure polypeptide derivative I.

Embodiment 3

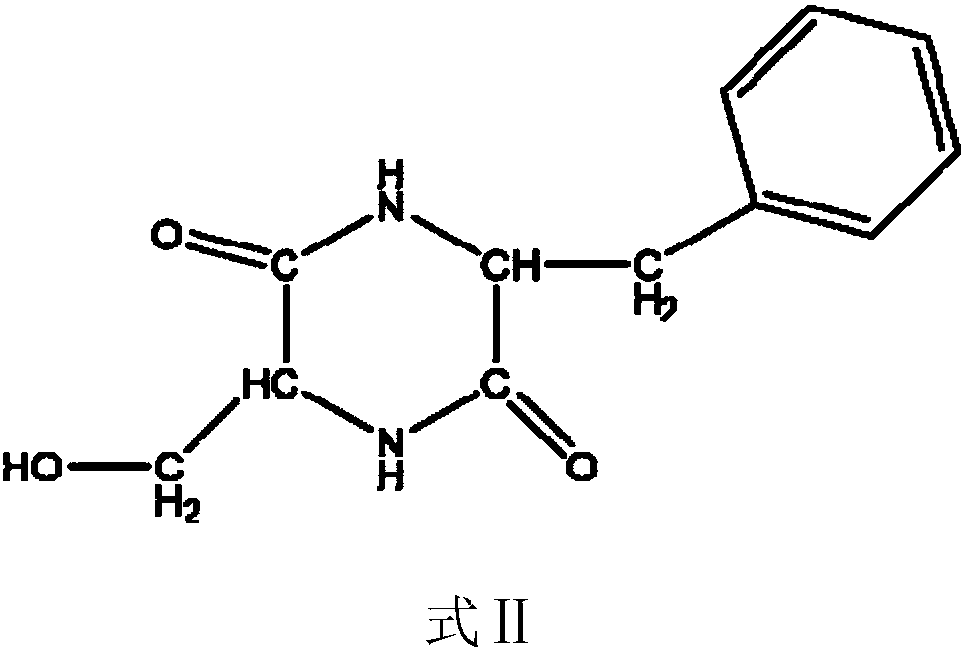

[0049] The preparation method of polypeptide Ser-Phe-Glu derivative (formula II), comprises the following steps:

[0050] The pH value of the pure polypeptide (10% solids concentration) system of Example 1 was adjusted to 6.5, and then heated at 110° C. for 90 minutes to obtain the polypeptide derivative II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com