Preparation method of telescopic MXene/graphene composite aerogel with high electromagnetic shielding effect

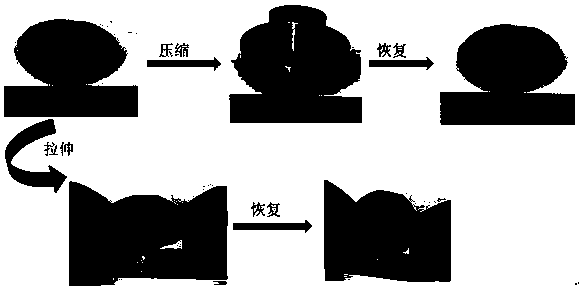

A graphene composite and electromagnetic shielding technology, which is applied in airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problem that the flexibility of the sheet is not as good as that of graphene, and achieve excellent scalability, simple method, and excellent Effects of conductivity and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

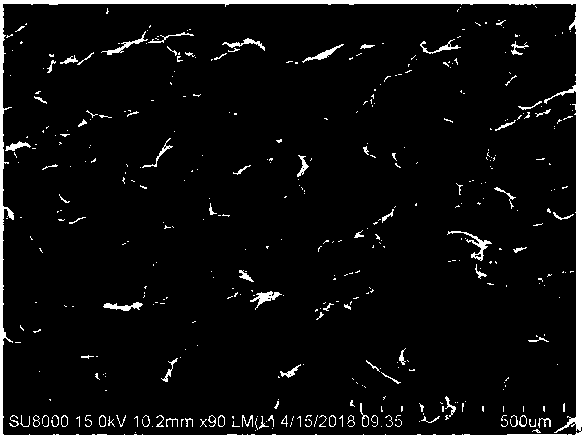

Examples

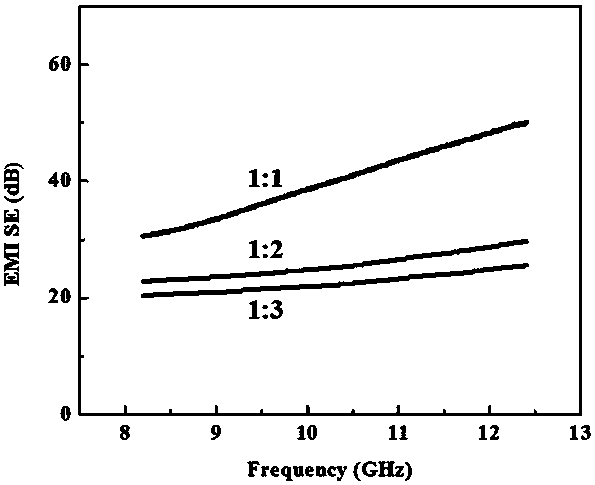

Embodiment 1

[0032] The scalable MXene / graphene composite airgel preparation method with high electromagnetic shielding effect provided by the present embodiment is realized through the following steps:

[0033] Step 1. Prepare reduced graphene oxide to a concentration of 4 mg mL -1 The reduced graphene oxide solution, i.e. solution A.

[0034] Step 2. Etching Ti by hydrofluoric acid 3 AlC 2 To prepare the MXene dispersion, and control its concentration to 1.5 mg mL with deionized water -1 . Mix the MXene dispersion with solution A at a mass ratio of 1:1 to obtain solution B.

[0035] Step 3. The solution B was magnetically stirred at a speed of 600 r / min for 30 minutes and then subjected to ultrasonic treatment for 40 minutes to obtain a solution C with an ultrasonic power of 200 W.

[0036] Step 4. Dissolve polyvinyl alcohol in deionized water, add it to solution C at a ratio of 5 wt%, and then magnetically stir it at 400 r / min for 20 min, and then perform 10 min of ultrasonic power...

Embodiment 2

[0040] The preparation method of the scalable MXene / graphene composite airgel with high electromagnetic shielding effect provided by the present embodiment is realized through the following steps:

[0041] Step 1. Prepare reduced graphene oxide to a concentration of 10 mg mL -1 The reduced graphene oxide solution, i.e. solution A.

[0042] Step 2. Etching Ti by hydrofluoric acid 3 AlC 2 to prepare the MXene dispersion and make up to a concentration of 3 mg mL with deionized water -1 . Mix the MXene dispersion with solution A at a mass ratio of 1:2 to obtain solution B.

[0043] Step 3. The solution B was magnetically stirred at a speed of 300 r / min for 20 minutes, and then ultrasonically treated for 30 minutes to obtain a solution C. The ultrasonic power was 100 W.

[0044] Step 4: Prepare a tris buffer solution with a pH of 8.5, then add solution C, and stir evenly, then add 4 wt% dopamine and stir magnetically at 400 r / min for 20 minutes, and then use 100W ultrasonic U...

Embodiment 3

[0048] The scalable MXene / graphene composite airgel preparation method with high electromagnetic shielding effect provided by the present embodiment is realized through the following steps:

[0049] Step 1. Prepare reduced graphene oxide to a concentration of 6 mg mL -1 The reduced graphene oxide solution, i.e. solution A.

[0050] Step 2. Etching Ti by hydrofluoric acid 3 AlC 2 To prepare MXene dispersion, and control its concentration to 2 mg mL with deionized water -1 . Mix the MXene dispersion with solution A at a mass ratio of 1:3 to obtain solution B.

[0051] Step 3. The solution B was magnetically stirred at a rotation speed of 500 r / min for 10 minutes, and then ultrasonically treated for 30 minutes to obtain a solution C. The ultrasonic power was 150 W.

[0052] Step 4: Add 3 wt% of cellulose nanofibers to solution C, then magnetically stir it at 200 r / min for 150 min, and then perform ultrasonic treatment at 150 W ultrasonic power for 200 min to obtain composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com