Detection compensation control system for aerostatic spindle

An aerostatic spindle and compensation control technology, applied in manufacturing tools, measuring/indicating equipment, large fixed members, etc., to achieve detection compensation control, real-time compensation for rotor unbalanced displacement, and good dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be described further below in conjunction with the accompanying drawings.

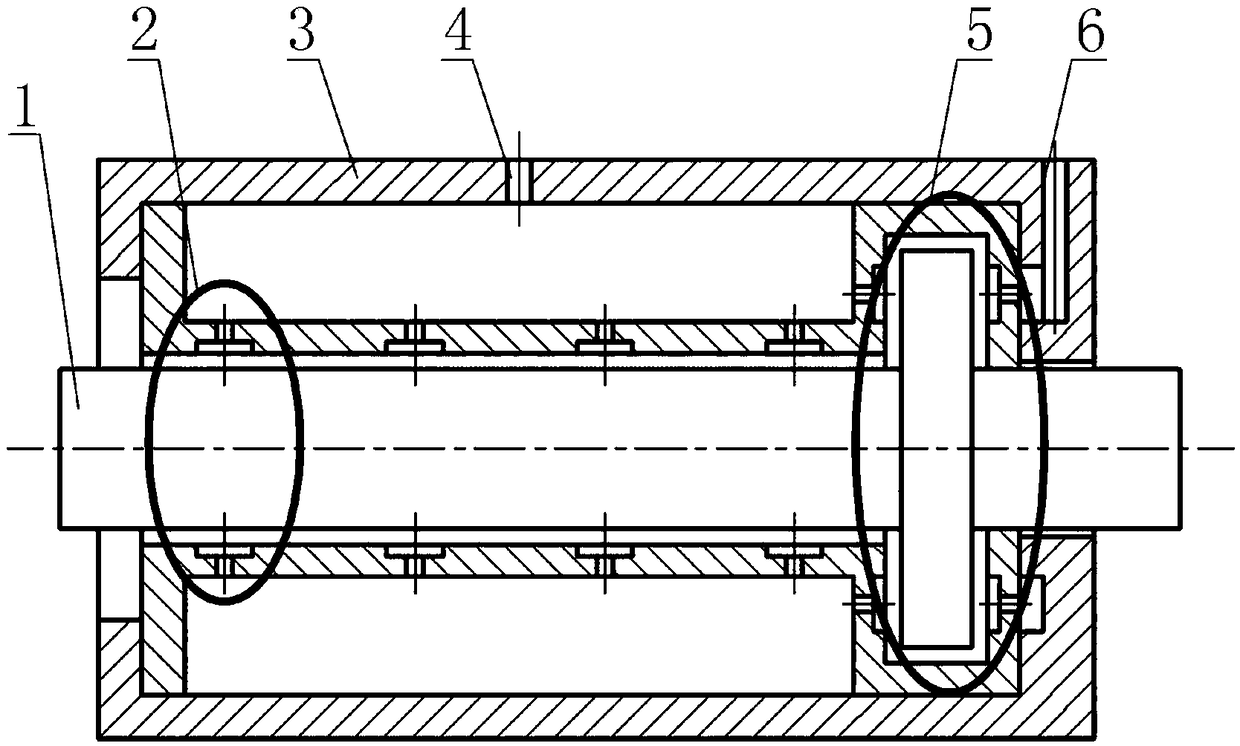

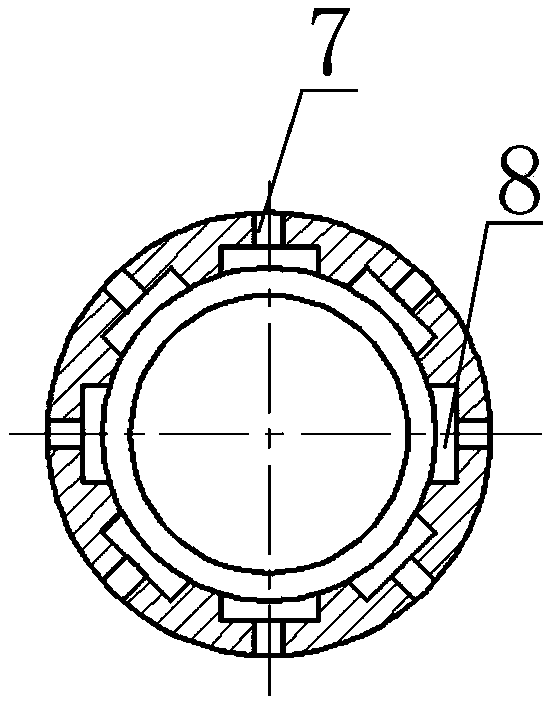

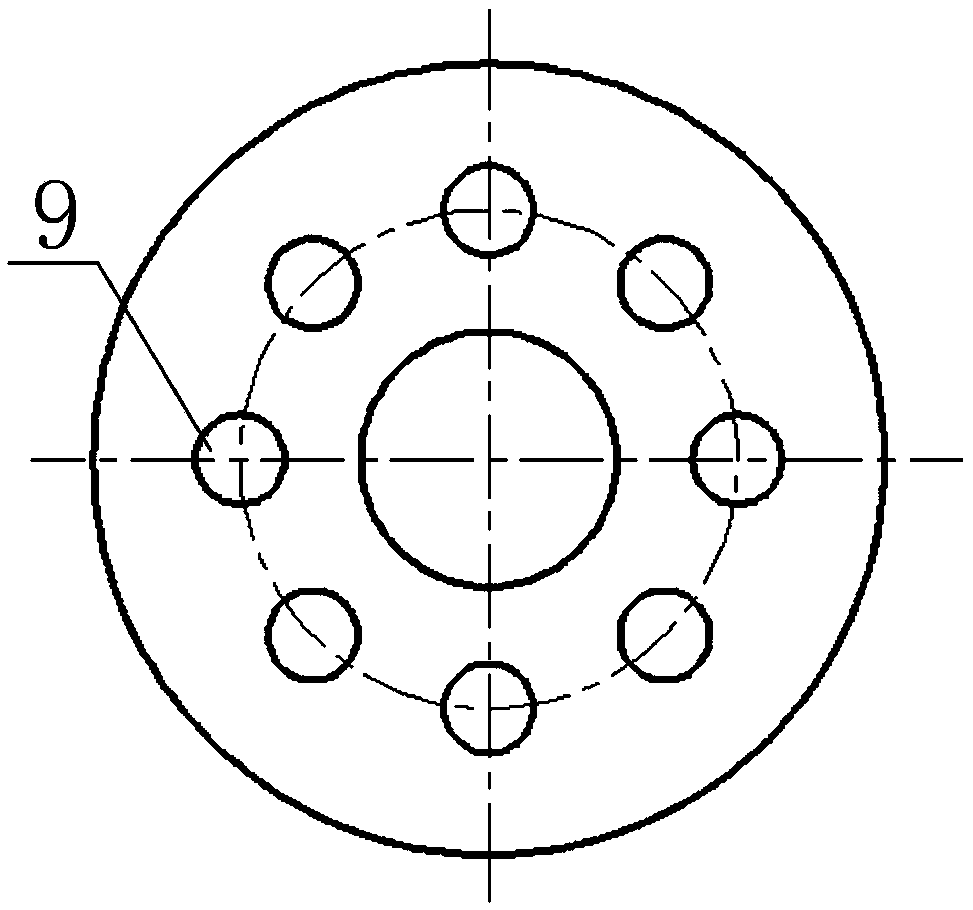

[0020] see figure 1 , the embodiment of the present invention is provided with an aerostatic spindle system. A detection compensation control system for an aerostatic spindle, the system includes a spindle rotor 1, a radial bearing 2, a bearing housing 3, a radial bearing air inlet 4, a thrust bearing 5, and a thrust bearing air inlet 6, The air enters the throttle hole and the air chamber through the radial bearing air inlet and the thrust bearing air inlet, forming a thin air film between the main shaft rotor 1 and the bearing sleeve, and the main shaft rotor 1 hardly generates friction.

[0021] This system includes a main shaft rotor 1, a radial bearing 2, a bearing housing 3, a radial bearing air inlet 4, a thrust bearing 5, and a thrust bearing air inlet 6. The main shaft rotor 1 is connected to and driven by a stepping motor, and has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com