Carbon nanotube fiber composite covering yarn and preparation method and application thereof

A carbon nanotube fiber and carbon nanotube composite technology, which is applied in the direction of yarn, textiles and papermaking, can solve the problems of affecting the performance of yarn or downstream materials, increasing the complexity of the process, and unfavorable production efficiency, etc., to achieve large-scale continuous production The effect of stable preparation, reduction of energy consumption and improvement of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

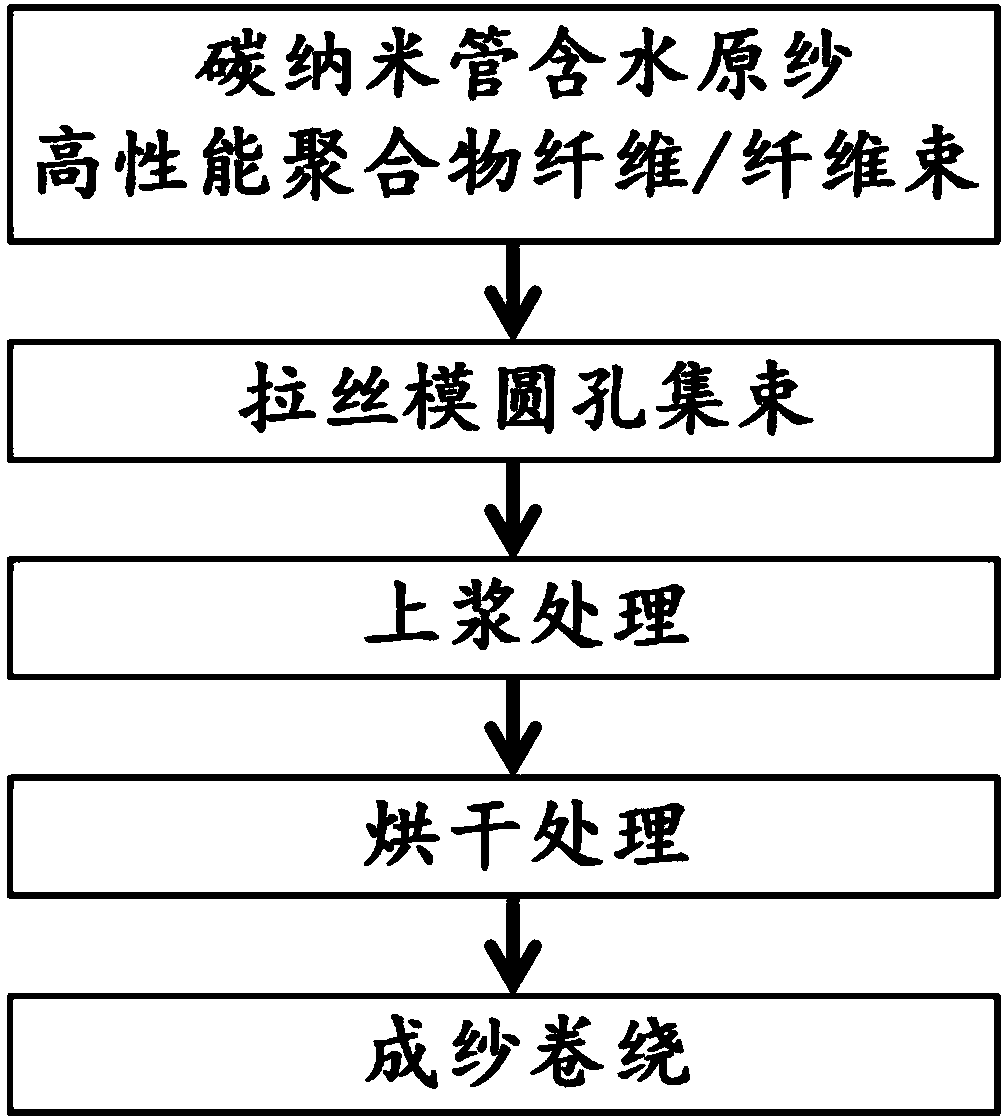

[0026] One aspect of the embodiments of the present invention provides a method for preparing a carbon nanotube fiber composite core-spun yarn, which includes:

[0027] Provide carbon nanotube water-containing raw yarn and polymer fiber;

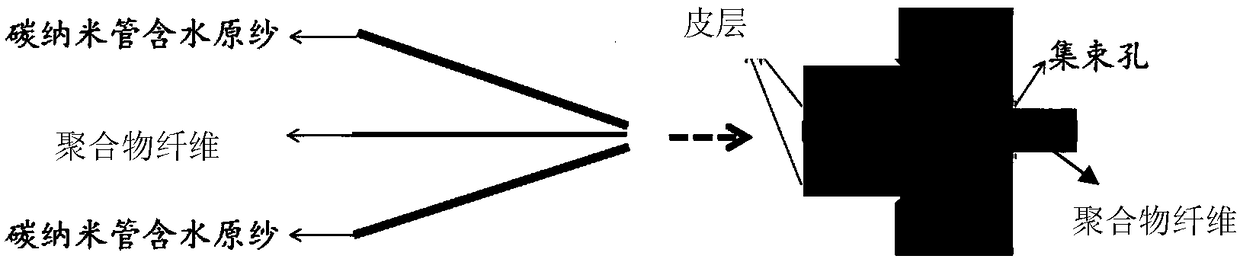

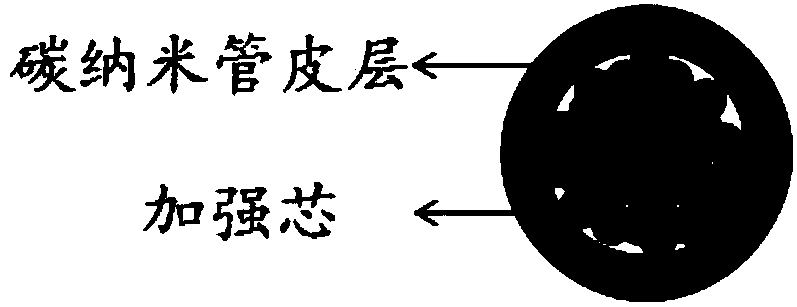

[0028] The carbon nanotube fiber composite core-spun yarn is formed by completely covering the surface of the polymer fiber with the carbon nanotube water-containing original yarn by adopting a round hole bundling technology.

[0029] The present invention has no limitation on the diameter and length of the carbon nanotube water-containing raw yarn and the polymer fiber. Moreover, the polymer fiber can be a monofilament or a fiber bundle, and the carbon nanotube water-containing original yarn can be one or more.

[0030] Preferably, the carbon nanotubes contained in the carbon nanotube water-containing raw yarn are fully infiltrated with water, wherein the mass of the water is 70 to 200 times that of the carbon nanotubes.

[0031] The carb...

Embodiment 1

[0063] Example 1: Take an ultra-high molecular weight polyethylene fiber (UHMWPE) with a single diameter of about 10 μm, and a water-containing raw yarn with a single width of about 60 μm and a mass ratio of water to carbon nanotubes of 70:1 to 80:1. At the same time, it passes through the drawing die hole with a diameter of 20 μm. After clustering, the carbon nanotube water-containing raw yarn is wrapped in the outer layer of UHMWPE to form a core-spun yarn. After the yarn is pulled out from the cluster hole, it enters the size tank for sizing treatment. Penetrating agent, softener and PVA solution with a concentration of 1wt%, the temperature of the size tank is 60°C, and then it enters the drying box for drying, the drying temperature is 60°C, and the walking time of the yarn in the drying box is 3 minutes , and finally wound onto a spool to form yarn. The tensile breaking load of the core-spun yarn formed in this embodiment is 480~520mN, and the conductivity is 3.2~3.6×10 ...

Embodiment 2

[0064] Embodiment 2: Take the ultra-high molecular weight polyethylene fiber (UHMWPE) bundle with a fineness of 150D / 72F, a water-containing raw yarn with a single width of about 3 mm, and a water-to-carbon nanotube mass ratio of 100:1 to 120:1, and two At the same time, it passes through the drawing die hole with a diameter of 250 μm. After the clustering, the carbon nanotube water-containing raw yarn is wrapped in the outer layer of UHMWPE to form a core-spun yarn. After the yarn is pulled out from the clustering hole, it enters the size tank for sizing treatment. Penetrating agent, softener and PVA solution with a concentration of 1%. The temperature of the size tank is 60°C, and then it enters the drying oven for drying. The drying temperature is 60°C, and the yarn travels in the oven for 3 minutes. Finally, Winding onto a spool to form yarn. The tensile breaking load of the core-spun yarn formed in this embodiment is about 4.5~5.2N, and the conductivity is 1.0~1.3×10 4 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com