Method for preparing supercapacitor carbon electrode material by using combined method

A technology of supercapacitors and carbon materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of energy waste, disadvantage, and low primary energy conversion and utilization efficiency, so as to overcome the collapse of mesopores and reduce costs. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

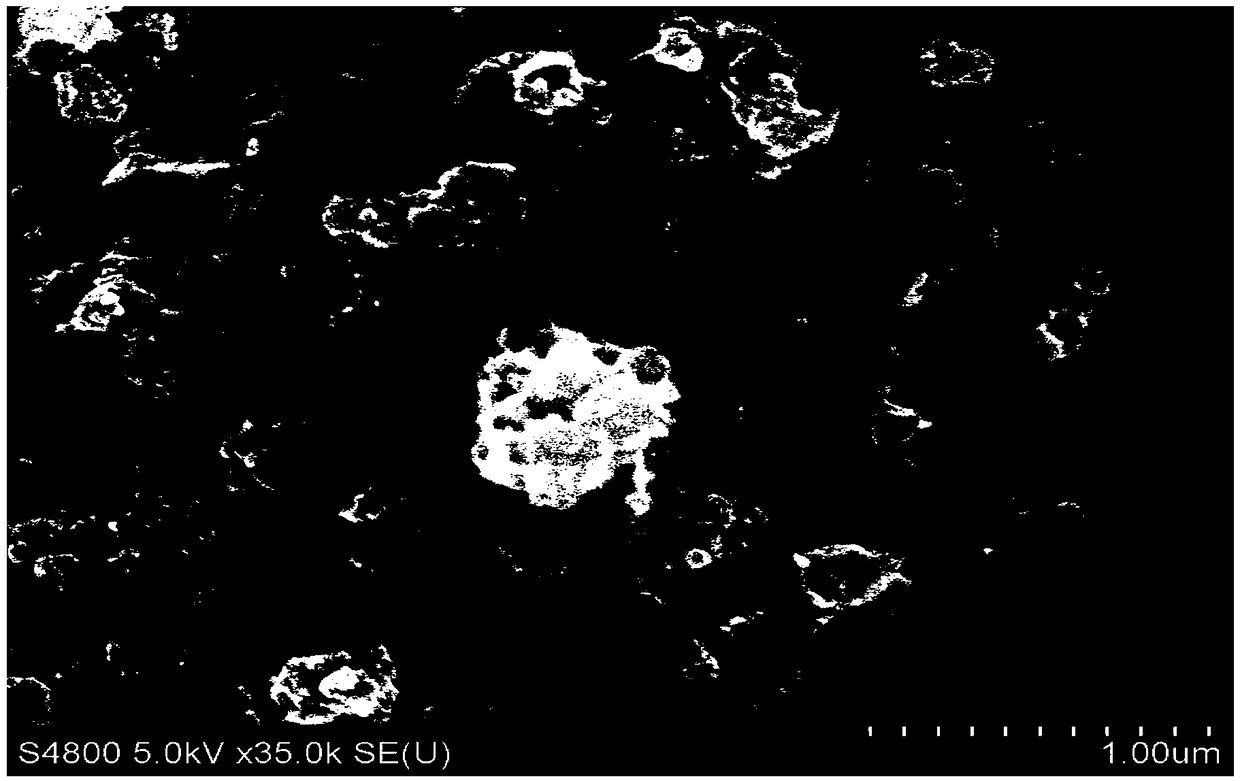

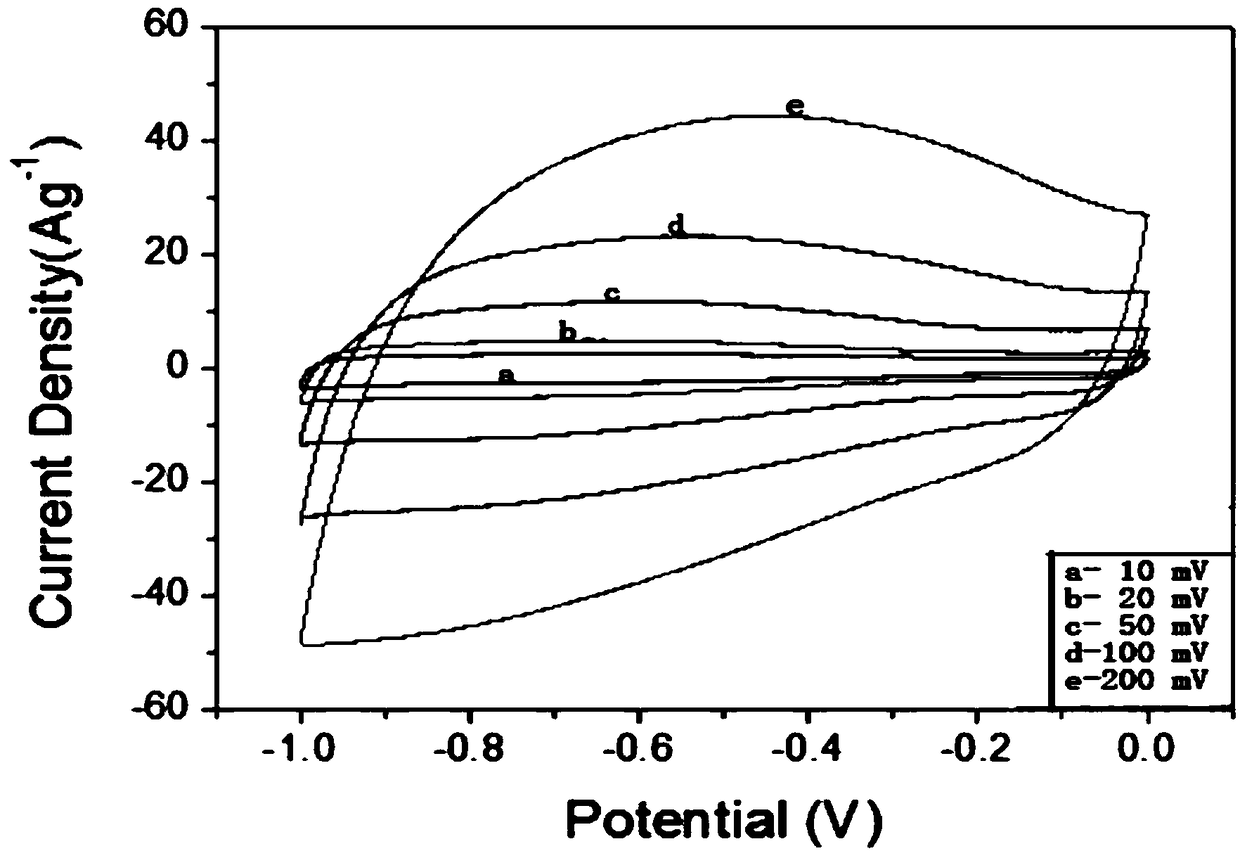

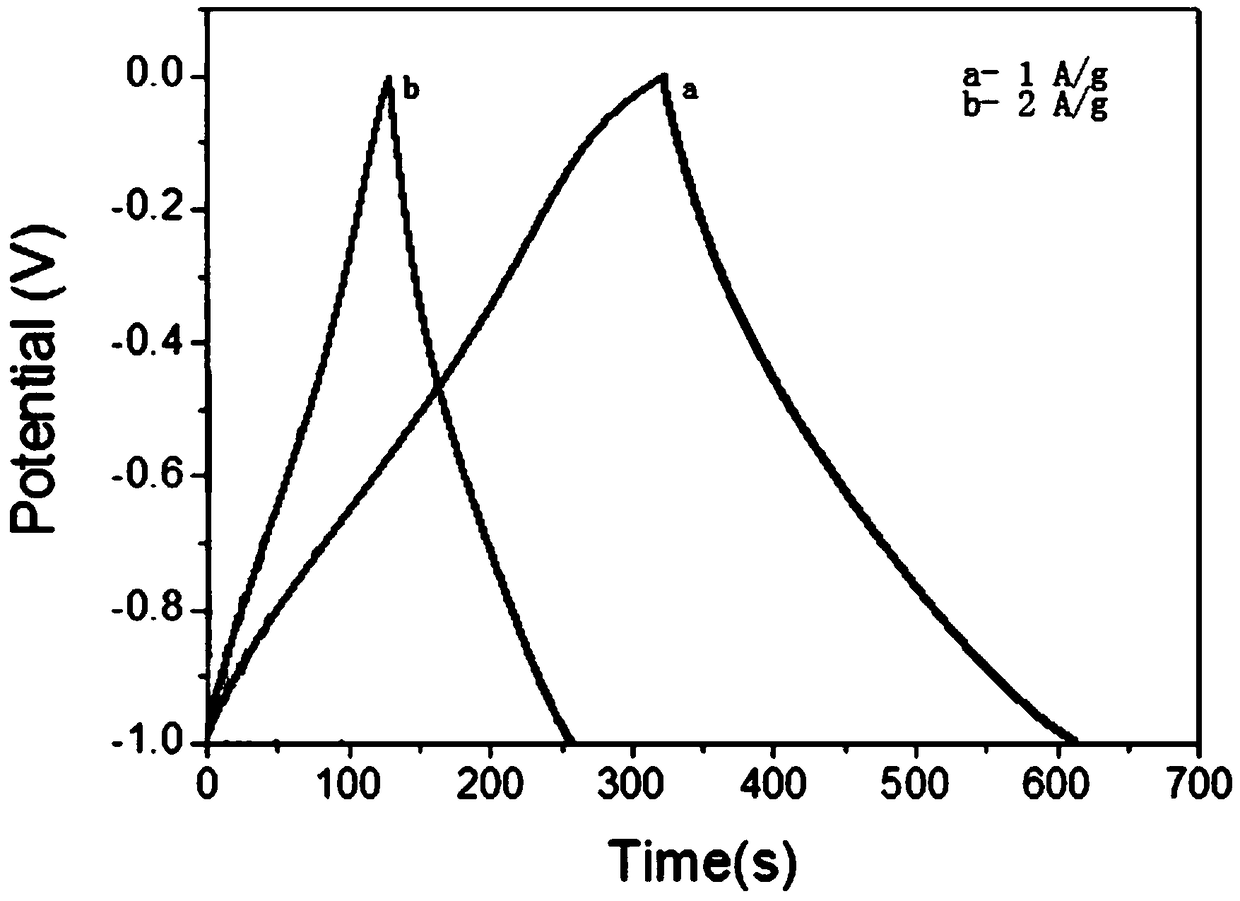

Image

Examples

Embodiment 1

[0024] 1. Preparation method

[0025] 1) Take discarded grapefruit peels and dry them in an oven at 90°C to constant weight. Take 25g of the dried peel, put it in a 500ml beaker, add 150ml of deionized water and a magnetic stirrer, cover with plastic wrap, and stir at a medium speed for 24h.

[0026] 2) Take out the insoluble matter, squeeze out the moisture absorbed by the peel with tweezers and put it in the original beaker. Make up to 150ml with deionized water. Add 0.5 g of anhydrous zinc gluconate granules, cover with plastic wrap, and stir at a medium speed for 24 hours. The mixture was transferred into a Petri dish and dried in an oven at 100°C.

[0027] 3) After drying, scrape up the solid matter, weigh it, put the solid into the combustion boat and lay it flat, push it into the center of the tube furnace, and turn on the nitrogen gas to flow into the tube furnace for 30 minutes. Cover the furnace plug and the nozzle cover. Turn on the tube furnace, heat up to 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com