A kind of ramie fiber harvesting method

A harvesting method, ramie fiber technology, applied in fiber processing, fiber mechanical separation, harvester, etc., can solve problems such as poor reliability, complex structure, and large loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is described below in conjunction with accompanying drawing.

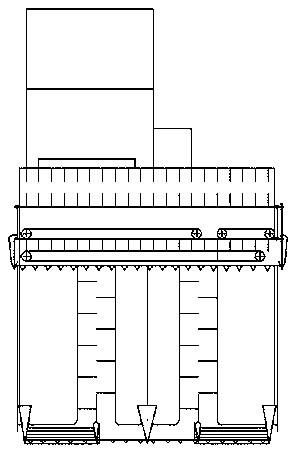

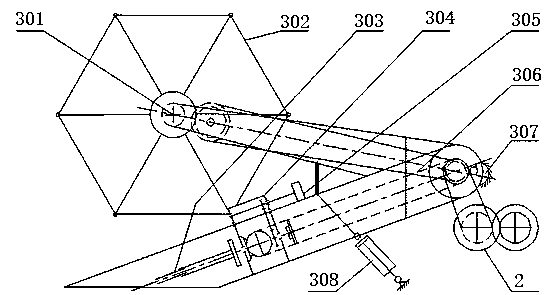

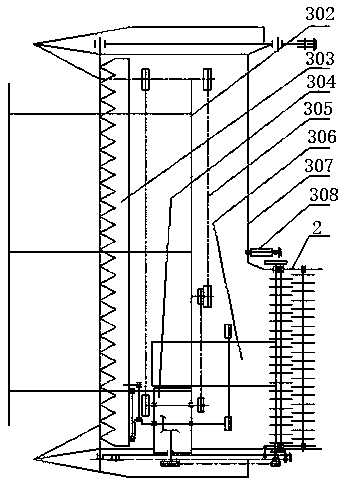

[0058] Such as figure 1 , figure 2 , image 3 The double-harvester ramie fiber-feeding double-harvesting combine shown in the figure consists of a vertical header 1, a shredder 2, a horizontal header 3, a control system 4, a power and power transmission system 5, a hemp removing machine 6, and a feed Storehouse 7, fiber storehouse 8, walking system 9 forms.

[0059] The horizontal header 3 and the vertical header 1 are arranged in the front, the shredder 2 is arranged in the upper right front, and the desemping machine is arranged in the upper right rear of the middle, and the horizontal header 3 and the shredder 2 are composed The hemp shoot (leaf) combined harvesting system, the vertical header 1 and the hemp threshing machine 6 form the hemp stalk fiber combined harvesting system, the control system 4, the engine and the power transmission system 5, and the walking system 9 form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com