Oil-water-soluble rosemary extract and preparation method and application thereof

A technology of rosemary extract and oil-water, which is applied in the field of oil-water soluble rosemary extract and its preparation, can solve the problems of limited application range, and achieve the effects of convenient use, low cost, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

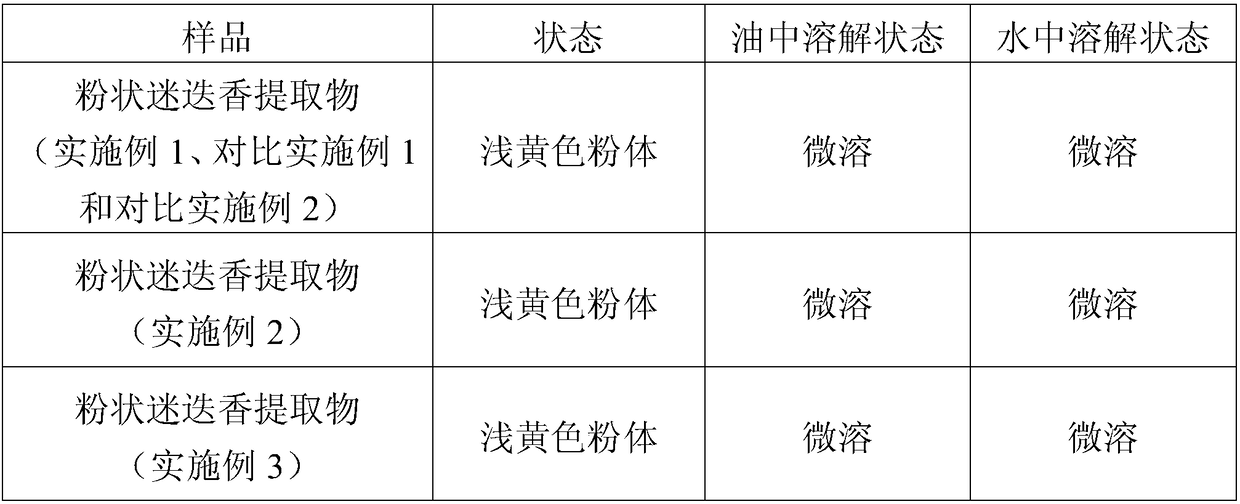

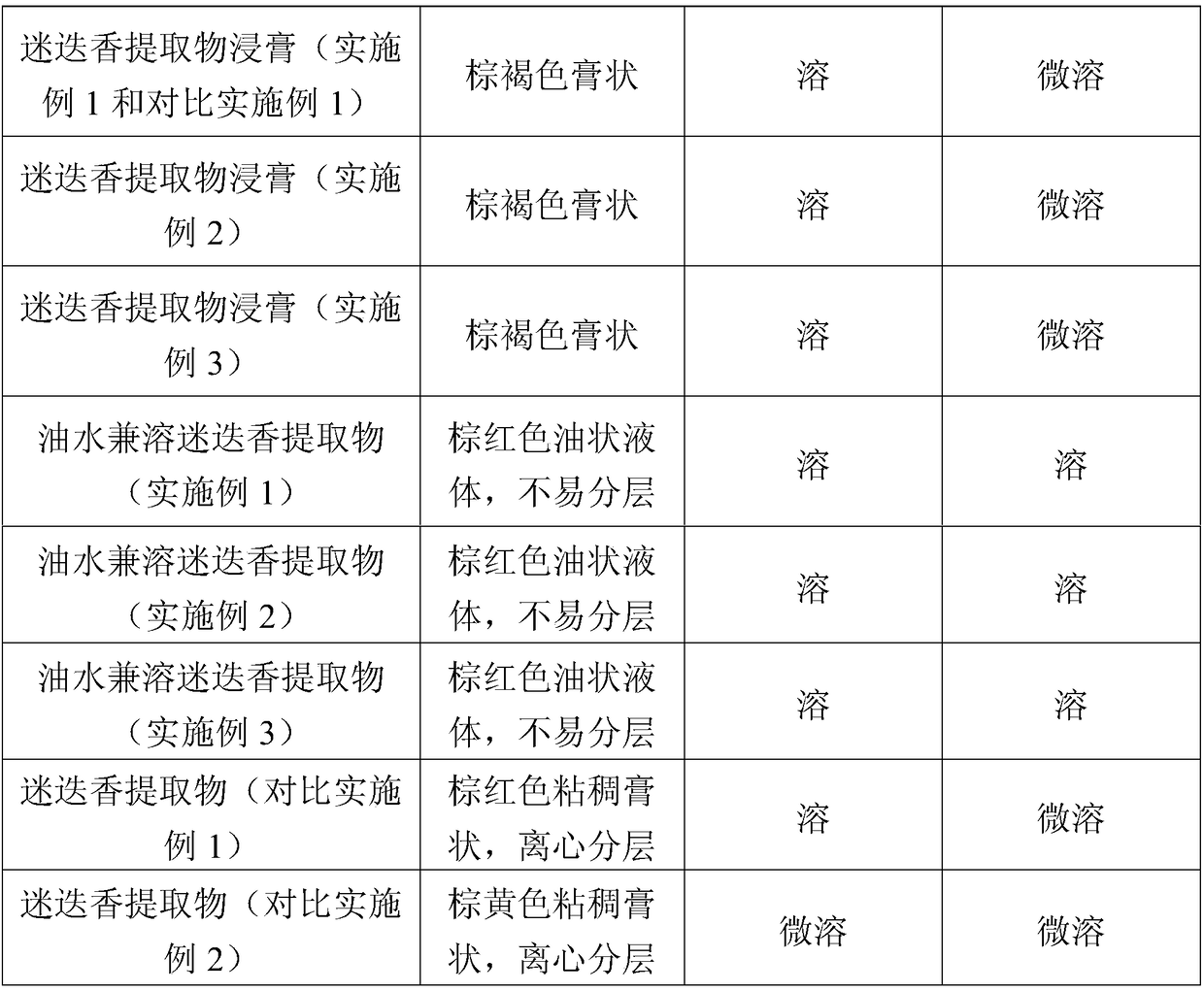

Examples

Embodiment 1

[0049] (1) get 10kg powdery rosemary extract (preparation method is with comparative example 2 step (1), wherein, carnosic acid and carnosol content add up to 25.1%) and 200kg vegetable oil extraction solvent mix, then 40 Under the condition of ℃, stir and extract at 80r / min for 30min, filter under normal pressure to obtain clear liquid;

[0050] (2) The clear liquid prepared in step (1) is concentrated under reduced pressure at 40~45°C and -0.04Mpa until there is no solvent residue, and 6.4kg of rosemary extract (carnosic acid and carnosic acid) are obtained. The glucophenol content is 31.2% in total);

[0051] (3) Place the rosemary extract extract prepared in step (2) in an emulsification kettle, preheat to 80°C, then add 6.4kg of oil-soluble emulsifier caprylic capric acid glyceride, at 80°C, 120r / Stir and emulsify for 30 minutes under the condition of min to obtain the mixed material;

[0052] (4) Add 3.2kg of water-soluble emulsifier Tween 80 to the mixed material pre...

Embodiment 2

[0054] (1) get 10kg powdery rosemary extract (preparation method is the same as comparative example 2 step (1), wherein, carnosic acid and carnosol content add up to 22.6%) and 250kg ethyl acetate mix, then 20 ℃ Under the conditions, stirring and extracting at 180r / min for 50min, filtering under normal pressure to obtain clear liquid;

[0055](2) Concentrate the clear liquid prepared in step (1) under reduced pressure at 30~35°C and -0.06Mpa until no solvent remains, and obtain 6.2kg of rosemary extract (carnosic acid and carnosic acid) The glucophenol content is 28.4% in total);

[0056] (3) Place the rosemary extract extract prepared in step (2) in an emulsification kettle, preheat to 70°C, then add 1.32kg of oil-soluble emulsifier caprylic capric acid glyceride, at 70°C, 80r / Stir and emulsify for 60min under the condition of min to obtain the mixed material;

[0057] (4) Add 1.32kg of water-soluble emulsifier Tween 80 to the mixed material prepared in step (3), stir and ...

Embodiment 3

[0059] (1) Get 10kg powdery rosemary extract (preparation method is the same as comparative example 2 step (1), wherein, carnosic acid and carnosol content add up to 35.7%) and 300kg ethyl acetate mix, then 50 ℃ Under heating conditions, stirring and extracting at 100r / min for 60min, filtering under reduced pressure to obtain clear liquid;

[0060] (2) Concentrate the clear liquid prepared in step (1) under reduced pressure under the conditions of 45~50°C and -0.05Mpa until no solvent remains, and obtain 6.3kg of rosemary extract (carnosic acid and carnosic acid) The grass phenol content is 45.8% in total);

[0061] (3) Put the rosemary extract prepared in step (2) in an emulsification kettle, preheat to 60°C, then add 3.15kg polyglycerol fatty acid ester, and put it under the conditions of 60°C and 180r / min Stir and emulsify for 50 minutes to obtain the mixed material;

[0062] (4) Add 3.15kg of water-soluble emulsifier sucrose fatty acid ester and 3.15kg of glycerin to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com