A kind of methanol gasoline composite additive and its preparation method and application

A compound additive, methanol gasoline technology, used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of methanol gasoline stability destruction, auto parts corrosion, oil quality impact, etc., to improve startability, The effect of increasing the calorific value of combustion, improving oil quality and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

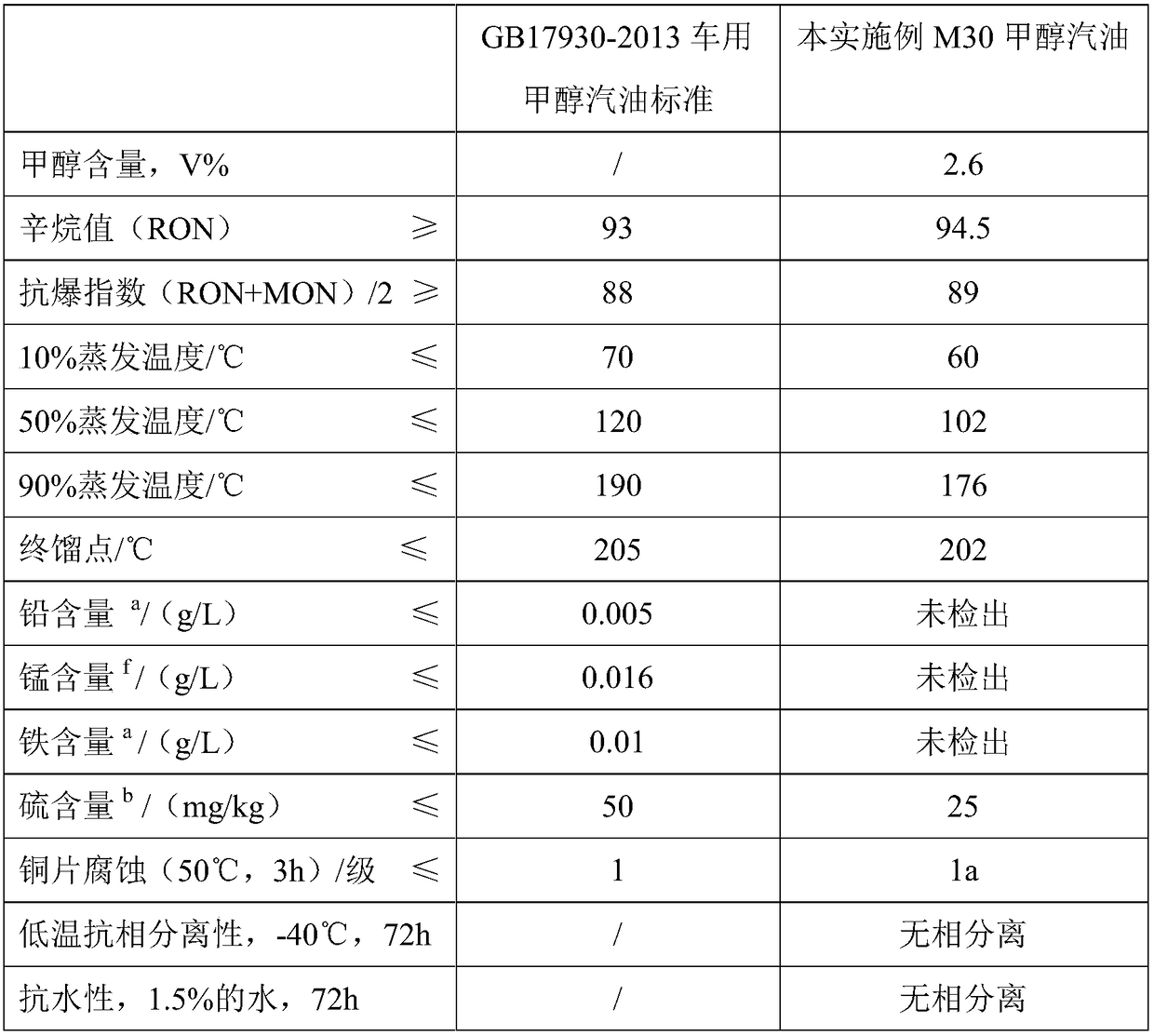

Embodiment 1

[0020] A methanol-gasoline composite additive and its application in M30, which is composed of the following raw materials in weight percentage: 70% of animal oil, 0.7% of vegetable oil, 0.3% of alkylbenzene, 0.25% of monoethanolamine, 0.25% of diethanolamine, and 0.25% of triethanolamine , 1.65% isooctyl nitrate, 1.65% isopropyl nitrate, 1.65% ethyl nitrate, 1.65% sodium hydroxide, 1.65% potassium hydroxide, 20% water.

[0021] The preparation method of a kind of methanol gasoline composite additive of the present invention comprises the following steps: (1) animal oil and water are miscible in the container in proportion and stirred for 15-25min to obtain mixed solution I; (2) monoethanolamine, diethanolamine and triethanolamine in proportion to mixed solution I, and after stirring, let it stand for 8 to 12 minutes to obtain mixed solution II; (3) put vegetable oil, potassium hydroxide and sodium hydroxide into mixed solution II in proportion and stir for 15 ~25min to obtain...

Embodiment 2

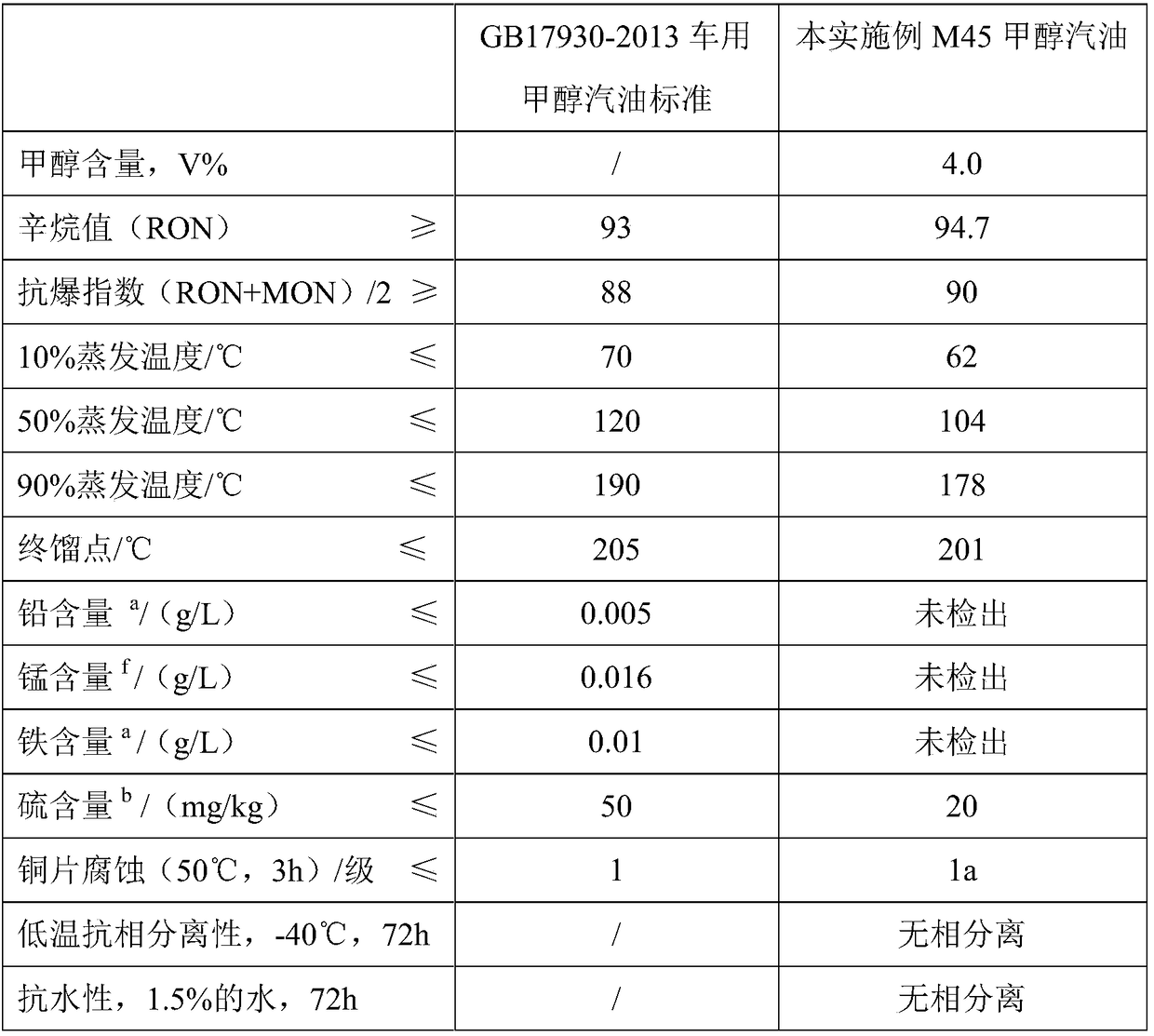

[0026] A methanol-gasoline compound additive and its application in M45, which is composed of the following raw materials in weight percentage: 68% of animal oil, 1.0% of vegetable oil, 0.5% of alkylbenzene, 0.7% of monoethanolamine, 0.7% of diethanolamine, and 0.6% of triethanolamine , 2.1% isooctyl nitrate, 2.1% isopropyl nitrate, 2.1% ethyl nitrate, 2.1% sodium hydroxide, 2.1% potassium hydroxide, 18% water.

[0027] The preparation method of composite additive in this embodiment is the same as embodiment 1.

[0028] A methanol-gasoline composite additive: methanol: 93# international gasoline volume ratio: 1:49:60 to prepare methanol-gasoline M45, the test results are shown in Table 2.

[0029] Table 2 The detection result of methanol gasoline M45 of the present invention

[0030]

Embodiment 3

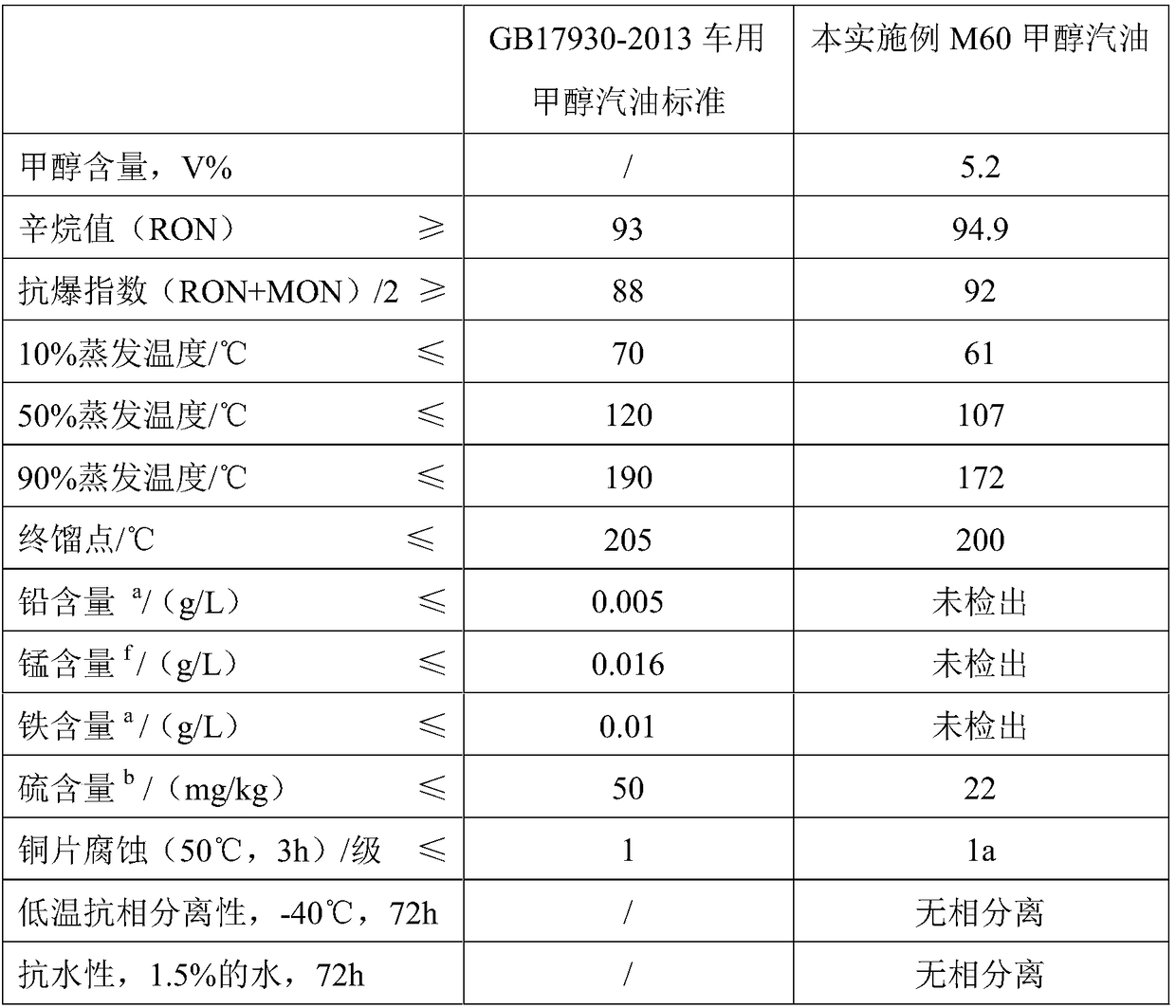

[0032] A methanol-gasoline composite additive and its application in M60, which is composed of the following raw materials in weight percentage: 72% of animal oil, 0.5% of vegetable oil, 0.2% of alkylbenzene, 0.1% of monoethanolamine, 0.1% of diethanolamine, and 0.1% of triethanolamine , Isooctyl nitrate 1.0%, Isopropyl nitrate 1.0%, Ethyl nitrate 1.0%, Sodium hydroxide 1.0%, Potassium hydroxide 1.0%, Water 22%.

[0033] The preparation method of composite additive in this embodiment is the same as embodiment 1.

[0034] A methanol-gasoline composite additive: methanol: 93# international gasoline volume ratio: 3:60:40 to prepare methanol-gasoline M60, the test results are shown in Table 3.

[0035] Table 3 The detection result of methanol gasoline M60 of the present invention

[0036]

[0037] As can be seen from Table 1, Table 2 and Table 3, the prepared composite additive of the present invention reduces the corrosivity of methanol gasoline to auto parts, improves the oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com