A kind of preparation method of hydrophilic polytetrafluoroethylene flat membrane

A technology of polytetrafluoroethylene and flat membrane, which is applied in the direction of chemical instruments and methods, membranes, membrane technology, etc. It can solve the problems of unsustainable modification effect, easy to appear holes, and different performances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

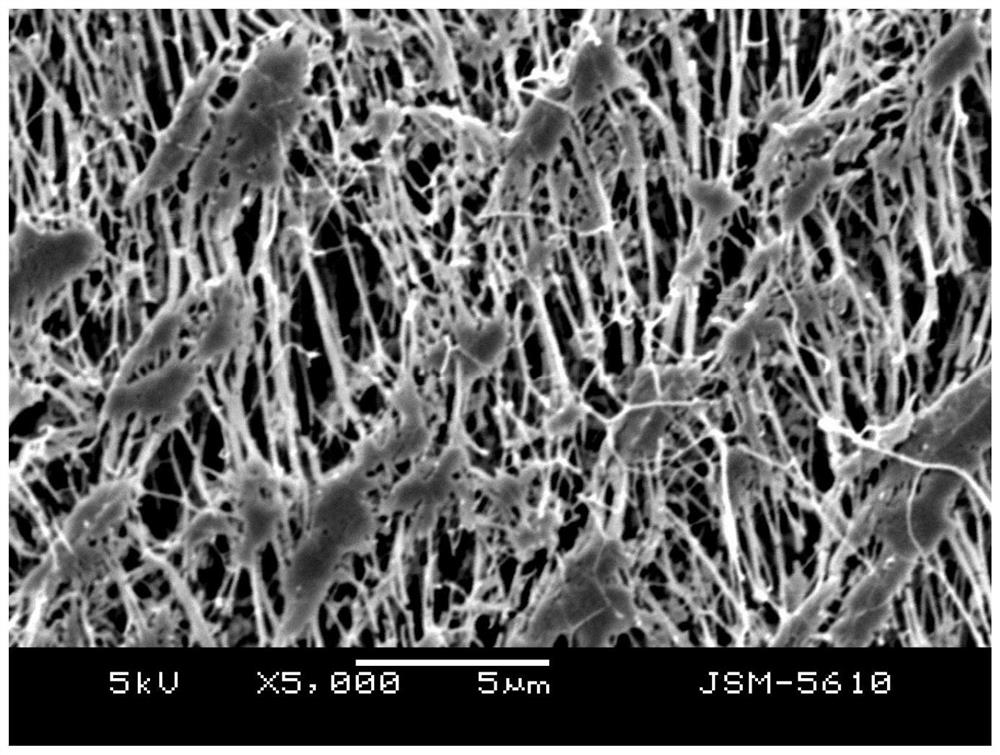

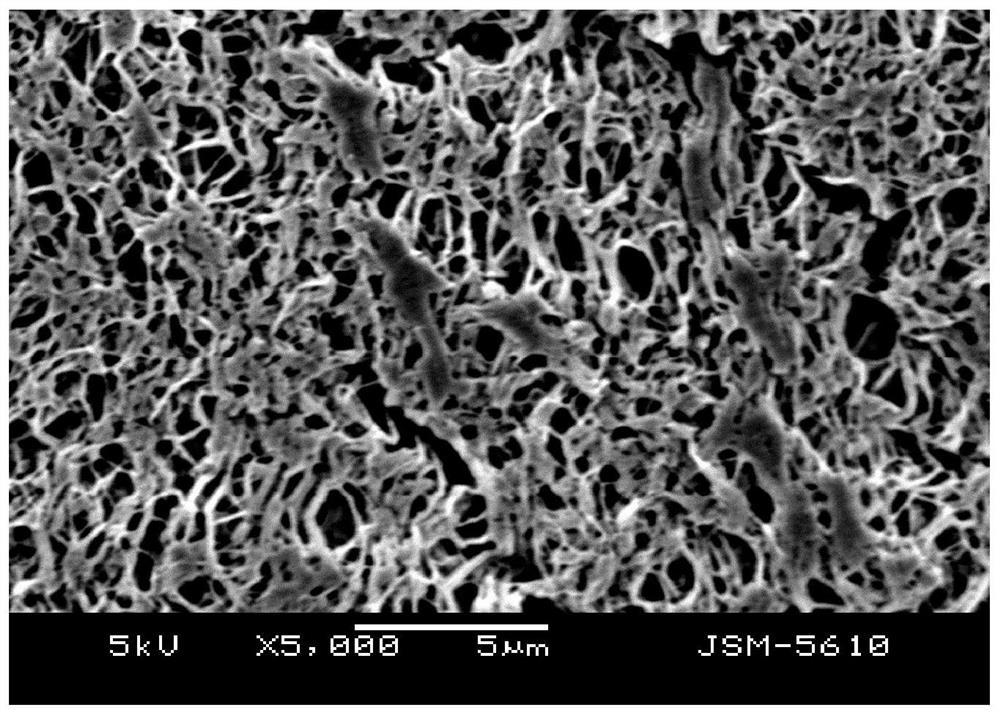

Image

Examples

Embodiment 1

[0030] 1. Relaxation treatment: wrap the PTFE flat film in a roll, place it in a closed container filled with water at a temperature of 130°C for 24 hours, then cool it down to 25°C at a rate of 1°C / min, take it out, and form a relaxed polymer Tetrafluoroethylene flat film;

[0031] 2. Filling: After uniformly mixing silica nanoparticles, ethanol, water, and γ-methacryloxypropyltrimethoxysilane according to the weight percentage of 1:3:0.1:0.01, the required filling material is obtained. The filling material is evenly scraped on the loose polytetrafluoroethylene flat film by a scraper to form a filled polytetrafluoroethylene flat film;

[0032] 3. Coating: Polyethylene glycol (600) diacrylate, acrylic acid, N,N-methylenebisacrylamide, azobisisobutyronitrile, and ethanol are mixed according to the weight percentage 1:3:0.01:0.01:10 After uniform mixing, the desired coating material is obtained, and the coating material is evenly scraped on the filled polytetrafluoroethylene fl...

Embodiment 2

[0039] 1. Relaxation treatment: wrap the PTFE flat film in a roll, place it in a closed container with water at 150°C for 10 hours, then cool it down to 25°C at a rate of 3°C / min, take it out, and form a relaxed polymer Tetrafluoroethylene flat film;

[0040] 2. Filling: Evenly mix silica nanoparticles, ethanol, water, and γ-methacryloxypropyltrimethoxysilane according to the weight percentage of 1:5:0.2:0.02 to obtain the required filling material. The filling material is evenly scraped on the loose polytetrafluoroethylene flat film by a scraper to form a filled polytetrafluoroethylene flat film;

[0041] 3. Coating: Polyethylene glycol (600) diacrylate, acrylic acid, N,N-methylenebisacrylamide, azobisisobutyronitrile, and ethanol are mixed according to the weight percentage 1:5:0.03:0.03:40 Mix evenly to obtain the required coating material, and scrape the coating material evenly on the filled polytetrafluoroethylene flat film with a scraper to form a coated polytetrafluoro...

Embodiment 3

[0046] 1. Relaxation treatment: wrap the PTFE flat film in a roll, place it in an airtight container filled with water at a temperature of 140°C for 18 hours, then cool it down to 25°C at a rate of 2°C / min, take it out, and form a relaxed polymer Tetrafluoroethylene flat film;

[0047] 2. Filling: Evenly mix silica nanoparticles, ethanol, water, and γ-methacryloxypropyltrimethoxysilane according to the weight percentage of 1:4:0.15:0.015 to obtain the required filling material. The filling material is evenly scraped on the loose polytetrafluoroethylene flat film by a scraper to form a filled polytetrafluoroethylene flat film;

[0048] 3. Coating: Polyethylene glycol (600) diacrylate, acrylic acid, N,N-methylenebisacrylamide, azobisisobutyronitrile, and ethanol according to the weight percentage 1:4:0.02:0.02:30 Mix evenly to obtain the required coating material, and scrape the coating material evenly on the filled polytetrafluoroethylene flat film with a scraper to form a coate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com