Aerated concrete drill plugging and pulling crane

A technology of aerated concrete and drilled crane, which is applied to cranes, traveling mechanisms, and trolley cranes, etc., can solve the problems of poor stability and single function, and achieve the effect of solving balance and stability, and the structure is simple and practical.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

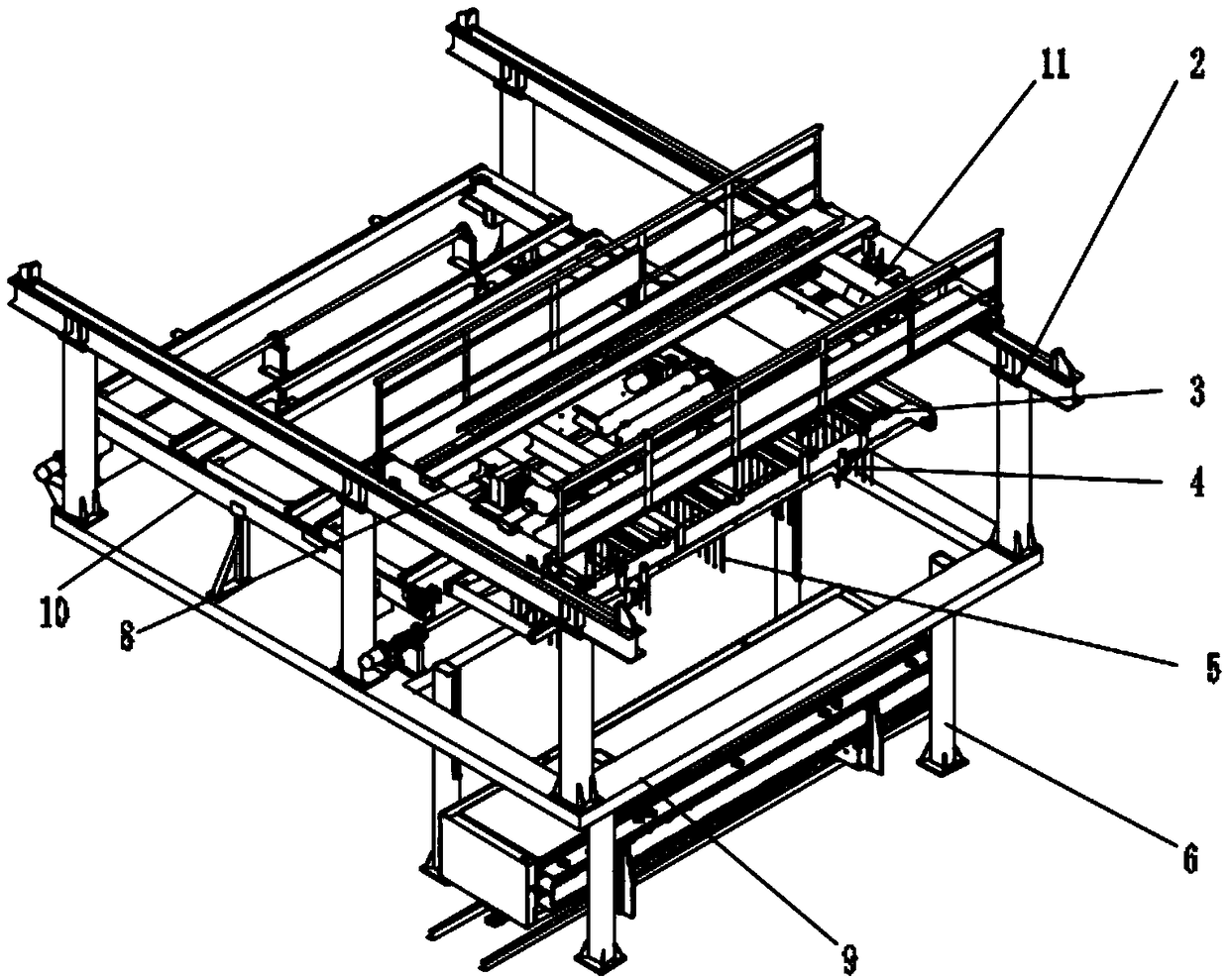

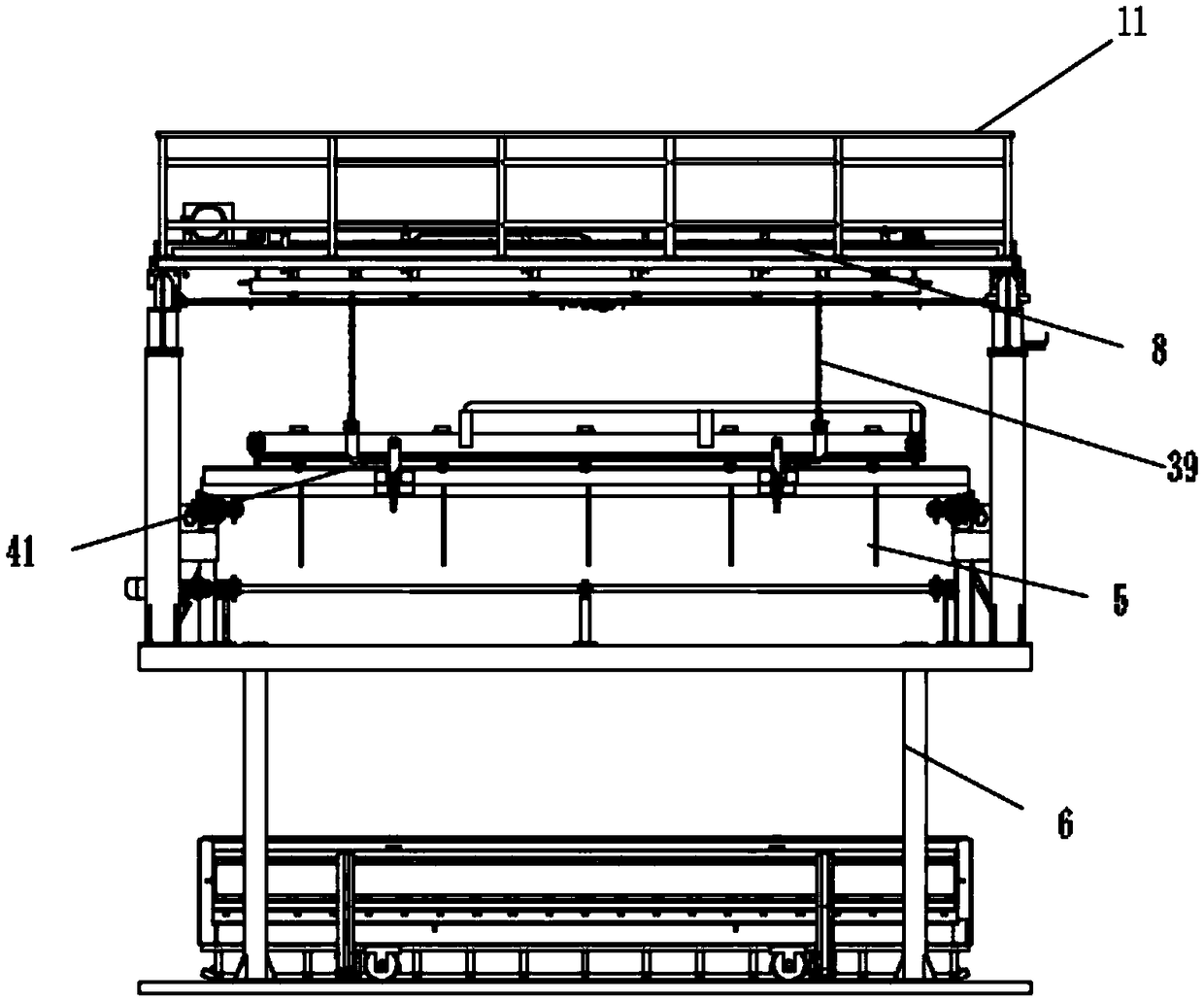

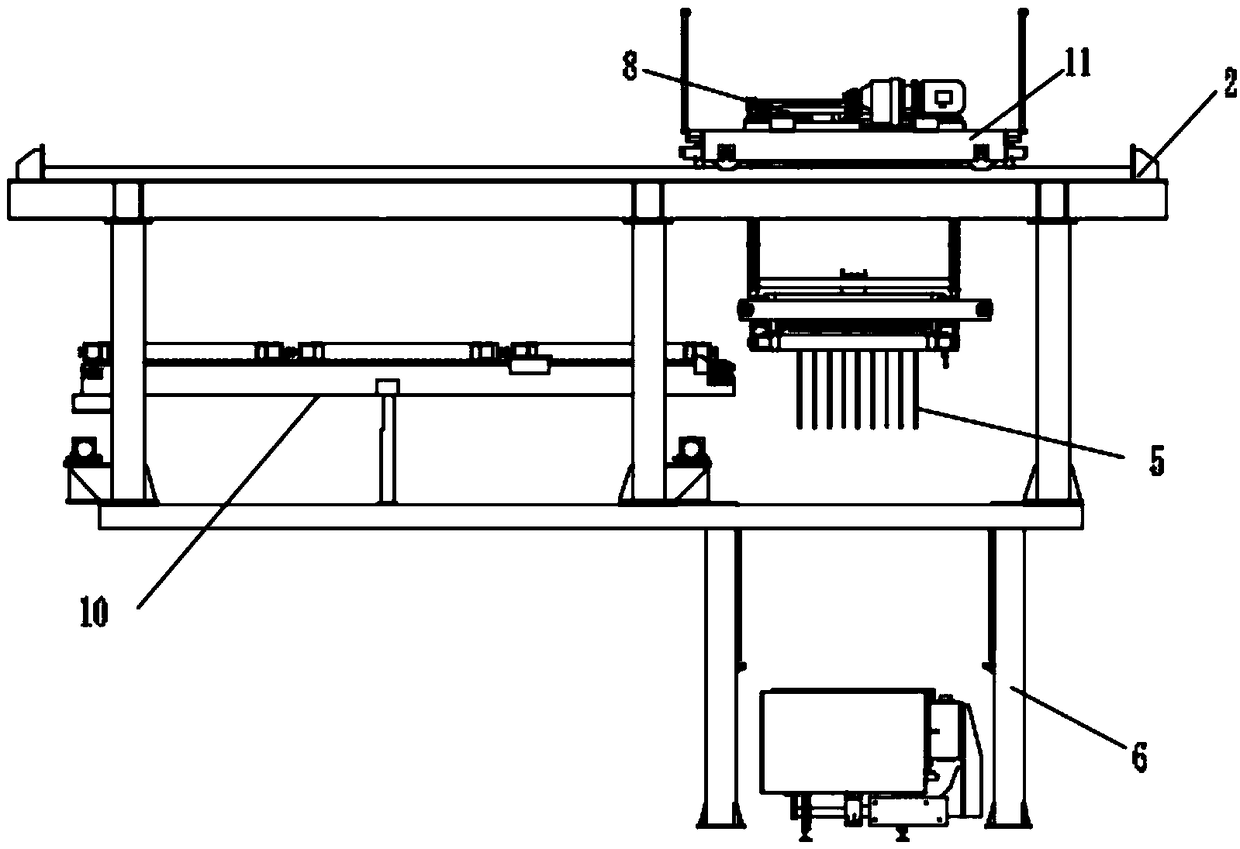

[0022] Such as Figure 1-6 As shown, this specific embodiment adopts the following technical solutions: an aerated concrete plug-in drill crane, including a crane body 1, and the crane body 1 is composed of a guide column 6, a floor 9, a beam column 2, and a cart 11 Composed of a spreader 3, the top of the guide column 6 is fixedly connected with a floor 9, and both sides of the top of the floor 9 are fixedly connected with a beam column 2 through a column with a seat 8, and the beam columns 2 are slidably connected with a A cart 11, the cart 11 is composed of a wheel assembly 30, a lifting chain assembly 28 and an inspection platform 31, the two ends of the cart 11 are rotatably connected to the wheel assembly 30, and the wheel assembly 30 The bottom of the cart 11 is slidingly connected with a light rail 26, and both sides of the cart 11 are fixedly connected with an inspection platform 31, and two main beams 27 are fixedly connected between the inspection platforms 31, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com