Synthesis technology of N-(ethoxycarbonylphenyl)-N'-methyl-N'-phenyl amidine

A technology of a carbonyl phenyl group and a synthesis process, applied in the field of chemical synthesis, can solve the problems of cumbersome reaction operation and post-processing, reduced yield and product purity, unfavorable industrial production, etc., and achieves high yield, low cost, and reaction time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

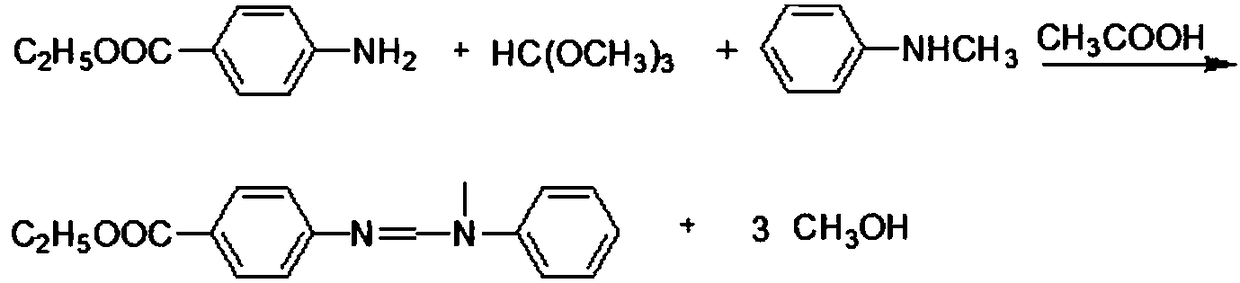

Image

Examples

Embodiment 1

[0034] A kind of synthetic technique of N-(ethoxycarbonylphenyl)-N'-methyl-N'-phenylamidine, comprising steps:

[0035] 1) Accurately weigh 16.5g of ethyl p-aminobenzoate, 16.5g of trimethyl orthoformate, and 16.8g of N-methylaniline into a 150mL three-necked flask, and add 60mL of petroleum ether into the three-necked flask, and put it into a magnetic stirrer A dropping funnel, a water separator and a thermometer were respectively placed on the three-necked flask, and the outer wall of the water separator was pre-passed with -5°C freezing liquid. Place the three-necked flask in a magnetic stirrer.

[0036] 2) Stir and heat up to the temperature in the three-necked flask to 50°C, add 9g of glacial acetic acid dropwise into the reaction vessel within 15min, and keep warm for 0.6h; heat up to 50°C, and react for 0.8h; then heat up to 65°C, and react for 0.6h; The liquid in the lower layer of the water separator is continuously separated, and the backflow is stopped at the upper...

Embodiment 2

[0041] A kind of synthetic technique of N-(ethoxycarbonylphenyl)-N'-methyl-N'-phenylamidine, comprising steps:

[0042] 1) Accurately weigh 16.5g of ethyl p-aminobenzoate, 11.7g of trimethyl orthoformate, and 12.1g of N-methylaniline into a 150mL three-necked flask, and add 40mL of petroleum ether into the three-necked flask, and put it into a magnetic stirrer A dropping funnel, a water separator and a thermometer were respectively placed on the three-necked flask, and the outer wall of the water separator was pre-passed with -3°C freezing liquid. Place the three-necked flask in a magnetic stirrer.

[0043] 2) Stir and heat up to the temperature in the three-necked flask to 40°C, add 5.5g of glacial acetic acid dropwise into the reaction vessel within 15min, and keep it warm for 1h; raise the temperature to 55°C, and react for 0.5h; then raise the temperature to 65°C, and react for 1h; Separate the liquid in the lower layer of the water separator, and stop the backflow at the...

Embodiment 3

[0048] A kind of synthetic technique of N-(ethoxycarbonylphenyl)-N'-methyl-N'-phenylamidine, comprising steps:

[0049] 1) Accurately weigh 16.5g of ethyl p-aminobenzoate, 29.7g of trimethyl orthoformate, and 30.1g of N-methylaniline into a 150mL three-necked flask, and add 50mL of petroleum ether into the three-necked flask, and put it into a magnetic stirrer A dropping funnel, a water separator and a thermometer were respectively placed on the three-necked flask, and the outer wall of the water separator was pre-passed with -7°C freezing liquid. Place the three-necked flask in a magnetic stirrer.

[0050] 2) Stir and heat up to the temperature in the three-necked flask to 60°C, add 14g of glacial acetic acid dropwise into the reaction vessel within 20 minutes, and keep warm for 0.5h; heat up to 65°C, and react for 0.5h; then heat up to 70°C, and react for 1h; Separate the liquid in the lower layer of the water separator, and stop the backflow at the upper end of the water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com