Microalgae sterile culture device and method suitable for mixotrophic culture

A culture device and microalgae technology, applied in the direction of microorganism-based methods, enzymology/microbiology devices, biochemical cleaning devices, etc., can solve the problems of easy contamination of miscellaneous bacteria, so as to avoid contamination of miscellaneous bacteria and improve biomass production rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

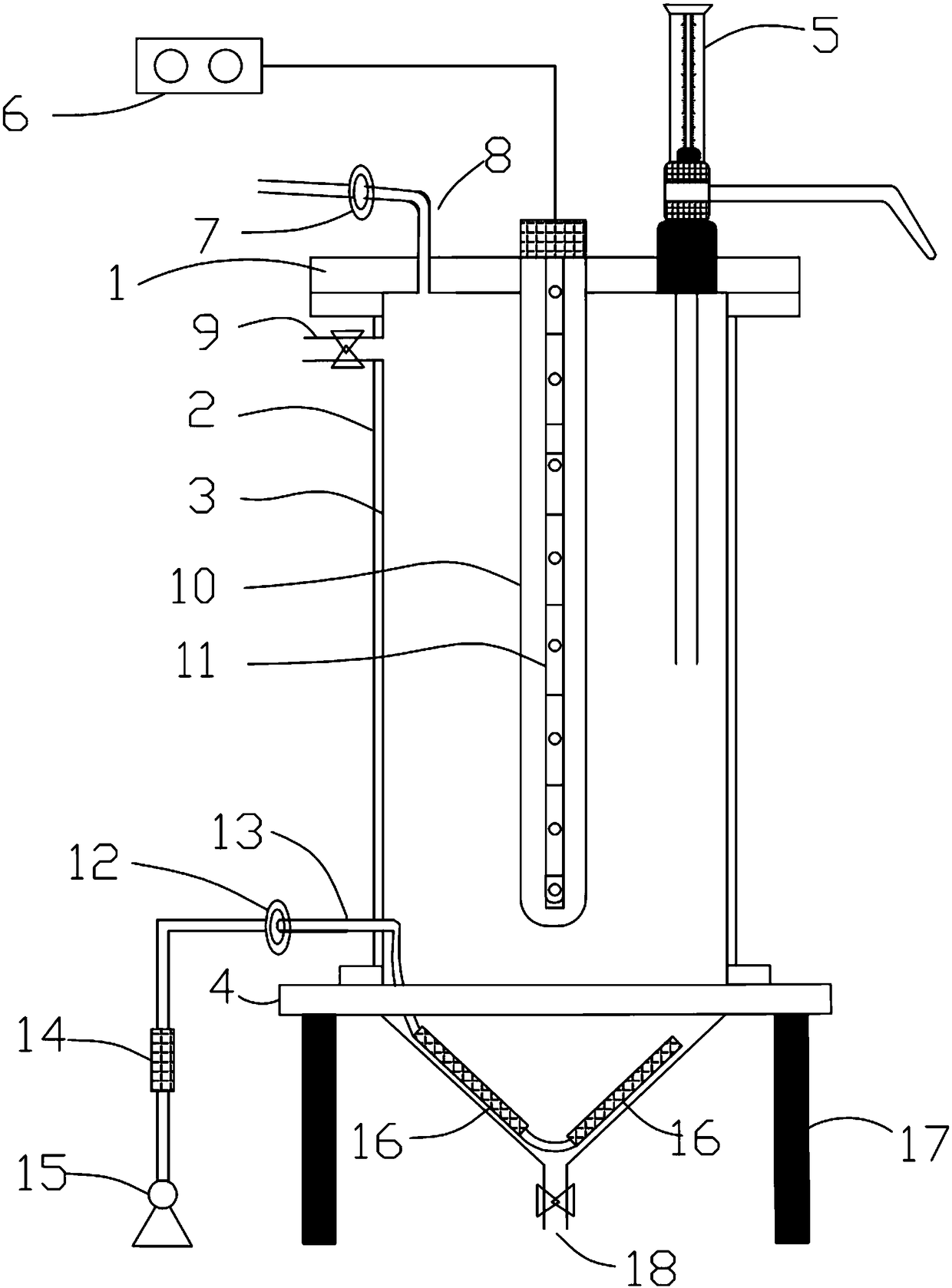

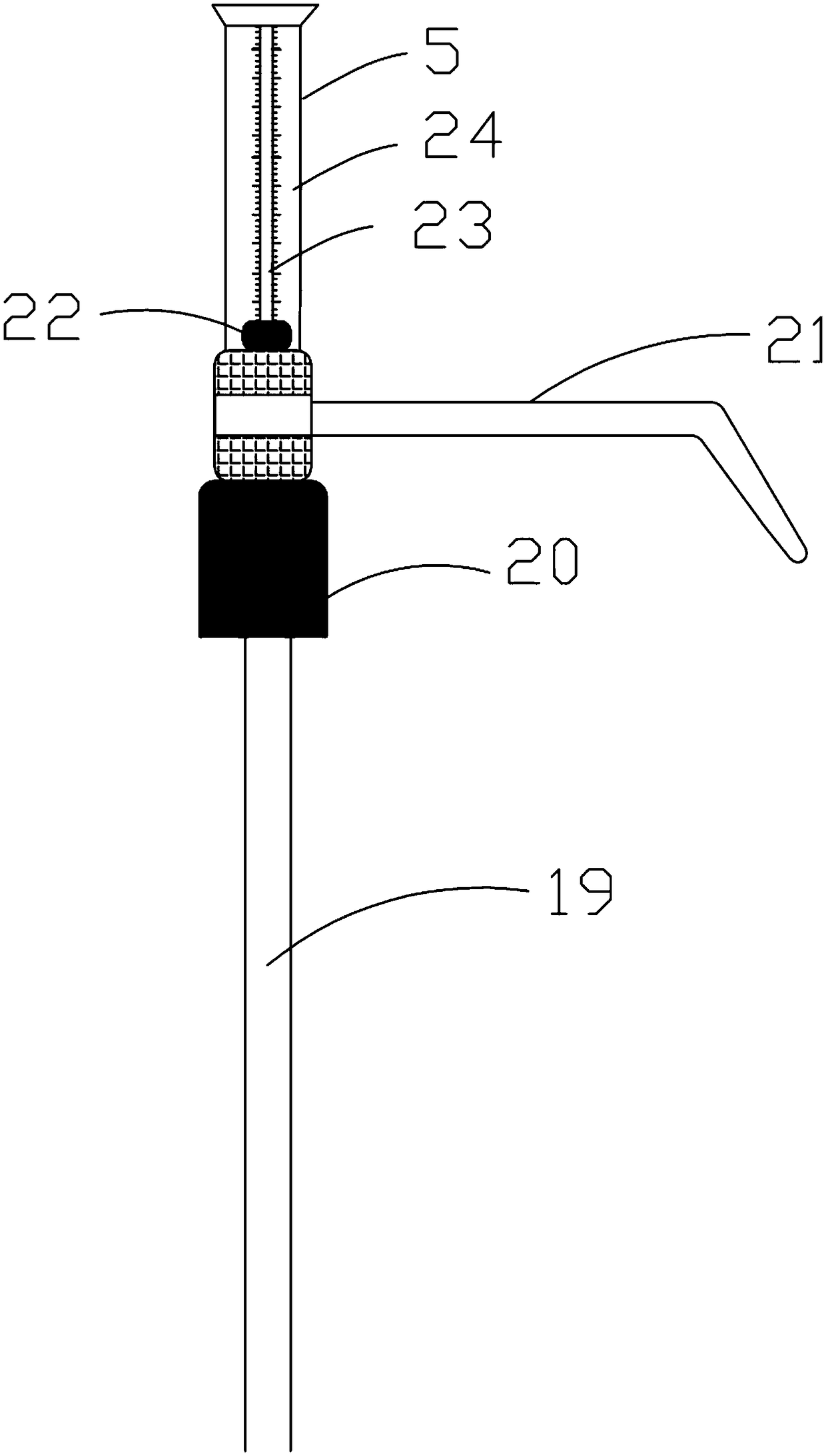

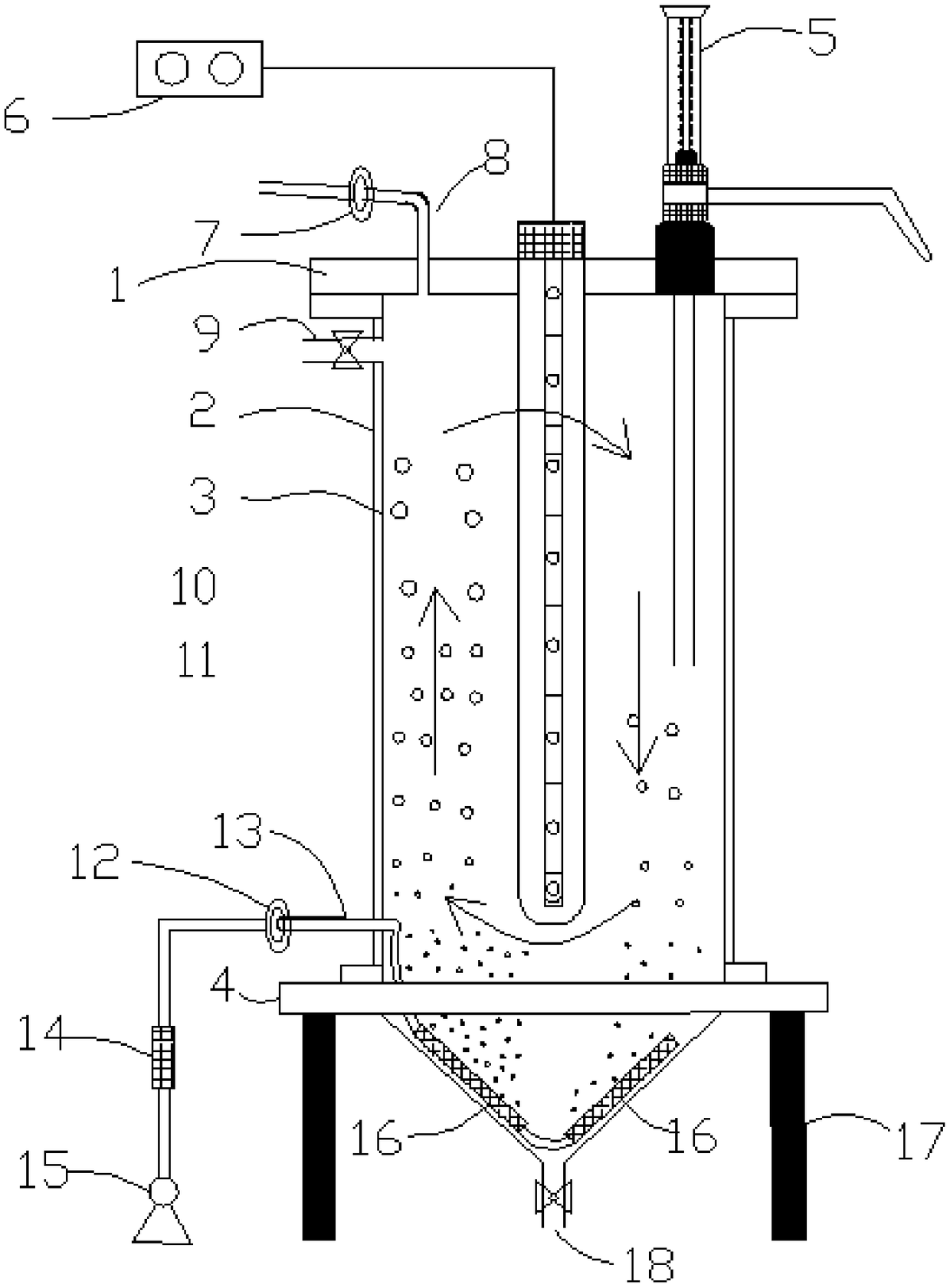

[0051] Such as Figure 1-3 Described, a microalgae aseptic culture device suitable for concurrent cultivation, the culture device comprises: a culture tank top cover 1, a tank body, a base 4, the upper and lower bottom surfaces of the tank body are open, and the culture tank The top cover 1 is detachably arranged at the opening of the upper bottom surface of the tank body, the lower bottom surface of the tank body is detachably connected with the base 4 , the bottom of the base 4 is a funnel-shaped structure, and the lower end of the funnel-shaped structure is provided with a discharge port 18 .

[0052] The tank body is composed of double walls, wherein the outer wall 2 is made of reflective material, the inner wall 3 is made of transparent material, the reflective material is a reflective one-way see-through film, and the transparent material is polyacrylic methyl acrylate, and the outer wall 2 of the tank is detachably pasted to the outer surface of the inner wall.

[0053...

Embodiment 2

[0061] A method for cultivating microalgae suitable for concurrent culture, comprising the steps of:

[0062] (1) thoroughly cleaning and disinfecting the microalgae aseptic culture device described in embodiment 1;

[0063] (2) Mix the isolated and purified strain of Septoria splendens with the sterile BG11 culture solution that added glucose, sucrose, soluble starch, sodium acetate, and sodium citrate as carbon sources, and add it to the culture medium under aseptic conditions. In the tank, the seeding density of algae cells was 10 6 cells / ml;

[0064] (3) The reaction system is placed in an artificial climate chamber, and the ambient temperature is set to 25°C;

[0065] (4) Adjust the initial light intensity to 2000 Lux, and increase the light intensity in the same proportion as the algae cell density increases, so that the average light intensity in the culture medium is stable;

[0066] (5) During the adjustment period, the logarithmic growth period and the stable peri...

Embodiment 3

[0070] A method for cultivating microalgae suitable for concurrent culture. The difference is that the tank body of the cultivating device has only an inner wall made of a transparent material, and does not include an outer wall made of a reflective material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inoculation density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com