RC-IGBT device and preparation method thereof

A technology of devices and drift regions, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as reliability, performance and hazards of devices in negative resistance regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

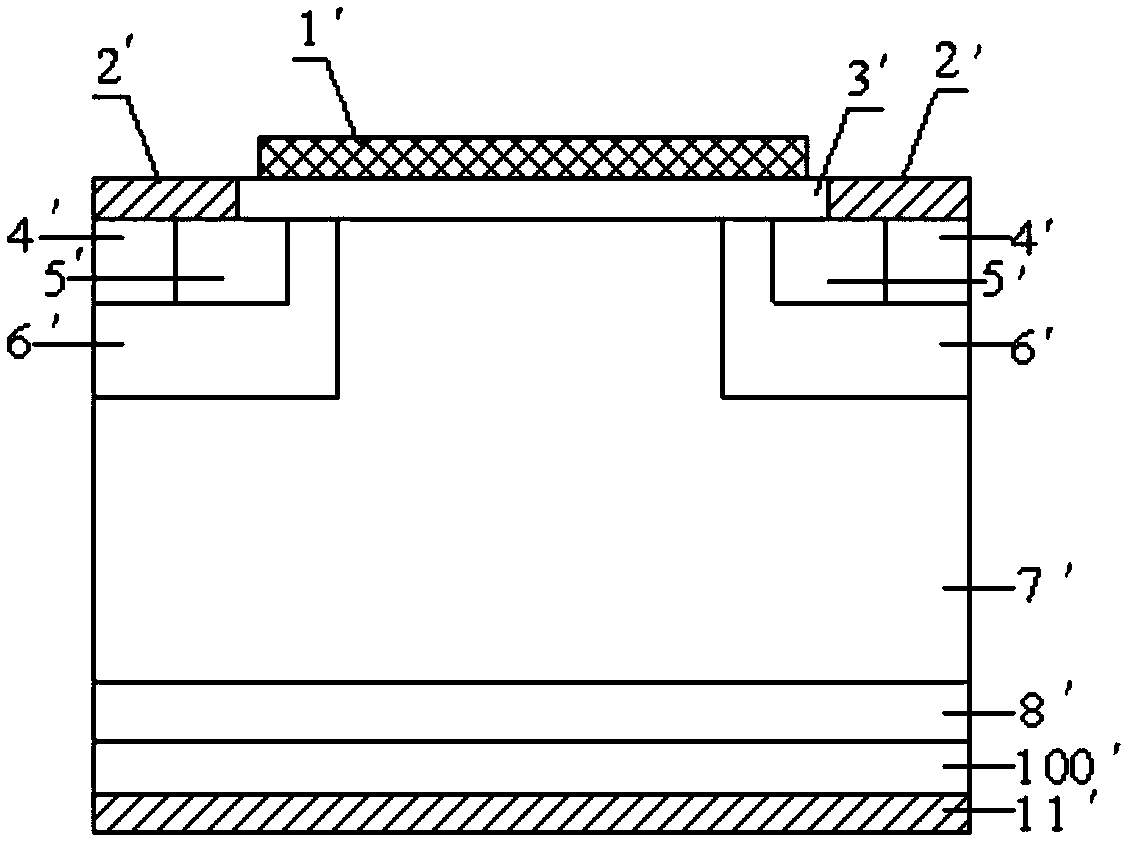

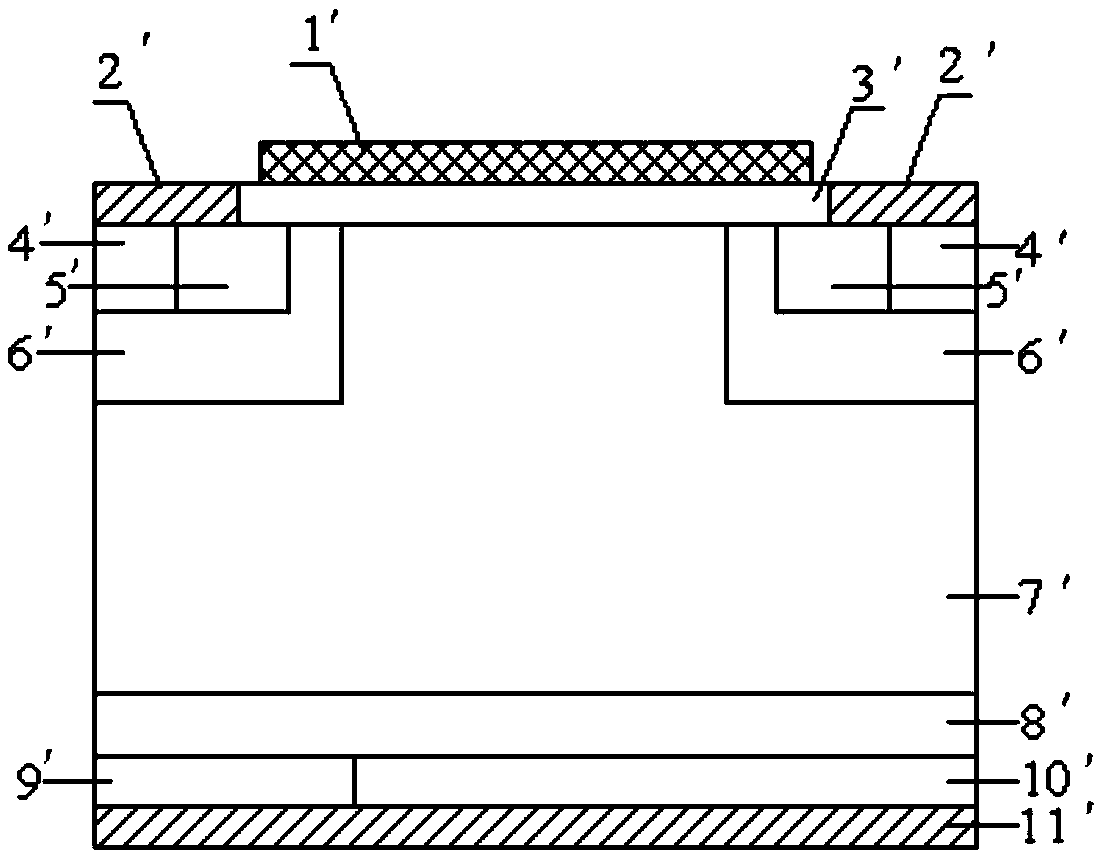

[0046]According to another aspect of the present invention, there is also provided a method for preparing an RC-IGBT device, comprising the following steps: forming a first substrate having a drift region 7 and a field stop region 8, the field stop region 8 being located on one side of the drift region 7 Both the drift region 7 and the field stop region 8 have the first conductivity type; the first collector region 10 and the second collector region 9 are formed on the side of the first substrate close to the field stop region 8, and the first collector region 10 It has a first end, and the first end runs through the field stop region 8 to isolate the field stop region 8 into a first stop region and a second stop region, and the part of the first collector region 10 other than the first end Set in contact with the first cut-off region, the second collector region 9 is arranged in contact with the second cut-off region, the second collector region 9 has the first conductivity ty...

Embodiment 1

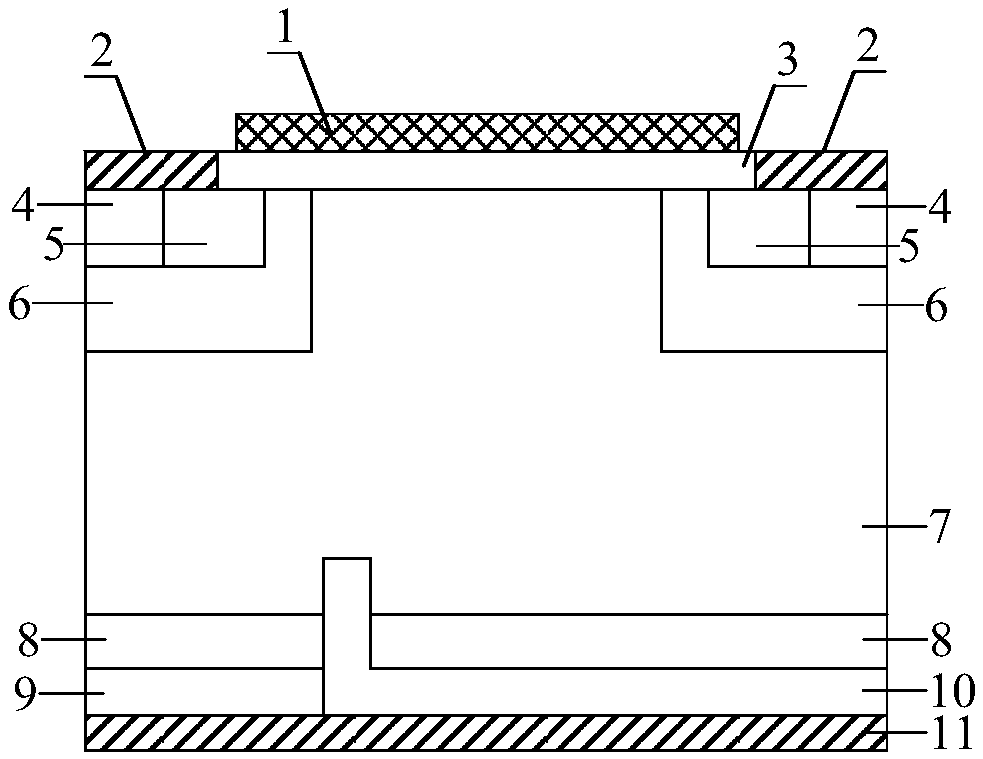

[0056] The RC-IGBT device provided by this embodiment is as image 3 As shown, its cells include gate 1, source 2, gate oxide layer 3, silicon carbide P + The contact area 4, silicon carbide N + The source region 5, silicon carbide P + The base region 6, silicon carbide N + The drift region 7, silicon carbide N + The field stop region 8, silicon carbide N + The second collector region 9, silicon carbide P + The first collector region 10 and the collector electrode 11 , the first collector region 10 has a first end portion, and the first end portion penetrates the field stop region 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com