A novel photocatalytic material and its preparation method and application

A photocatalytic material, a new type of technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of mild preparation conditions, phase transfer promotion, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 5g of melamine and place it in a crucible, cover tightly and place it in a muffle furnace for calcination. The calcination temperature is 550°C, and the calcination time is 5h. Take it out at room temperature to obtain the pure phase g-C 3 N 4 .

[0032] Such as figure 1 Shown in c, g-C prepared for the implementation of the present invention 3 N 4 physical map.

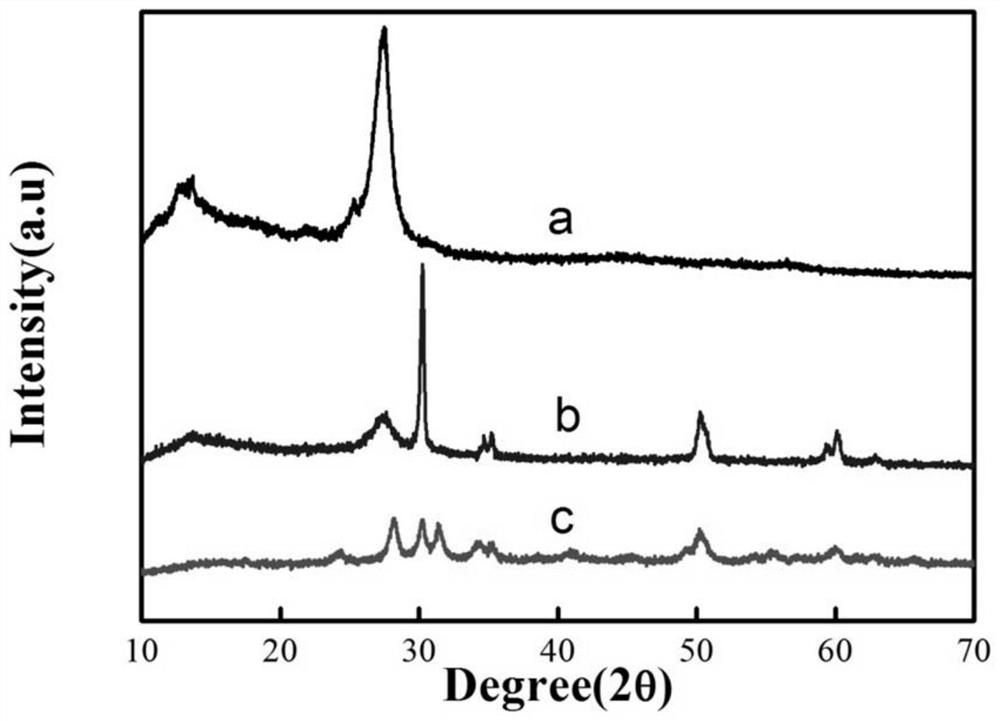

[0033] Such as figure 2 Shown in the line a in the middle, g-C prepared for the implementation of the present invention 3 N 4 The XRD picture, shows that the prepared g-C 3 N 4 With graphite phase crystal.

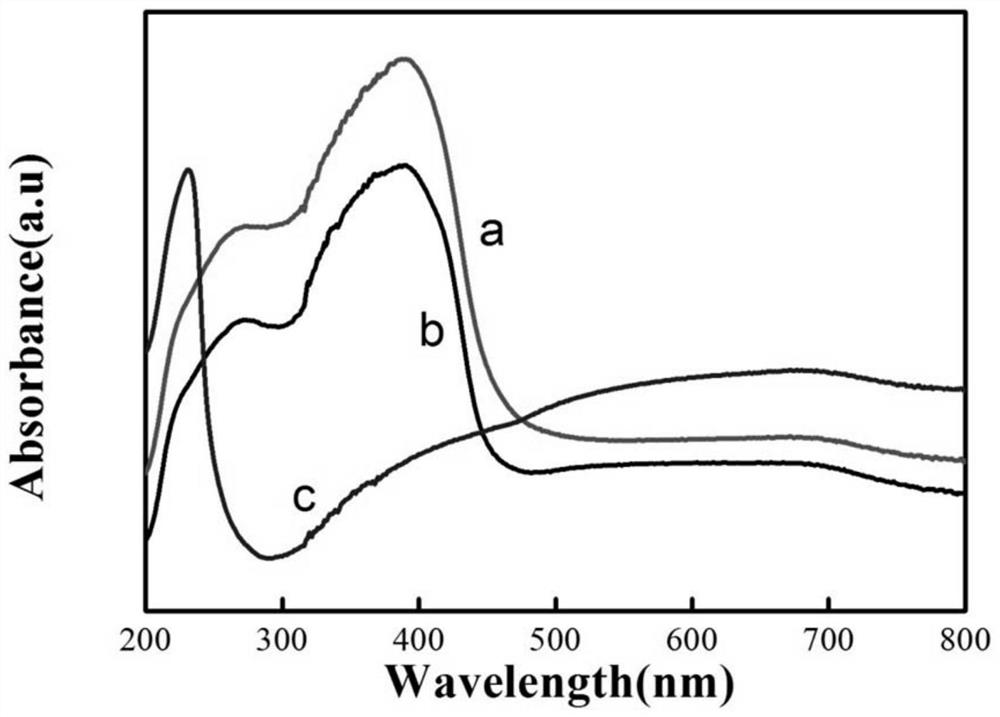

[0034] Such as image 3 Shown in the b line in the middle, it is the layered g-C prepared by the implementation of the present invention 3 N 4 The UV-Vis absorption spectrum of the prepared layered g-C 3 N 4 It can absorb visible light, and has a certain absorption capacity in the range of 600-800nm.

Embodiment 2

[0036] Weigh 5g of zirconium nitrate and place it in a crucible, cover tightly and place it in a muffle furnace for calcination. The calcination temperature is 550°C, the calcination time is 5h, and the pure phase ZrO is obtained by taking it out at room temperature. 2 .

[0037] Such as figure 1 Shown in a, is the ZrO prepared by the implementation of the present invention 2 physical map of

[0038] Such as figure 2 Shown in line c in the middle, it is the ZrO prepared by the implementation of the present invention 2 The XRD picture shows that the ZrO prepared by direct calcination of zirconium nitrate 2 It has the characteristics of co-existence of monoclinic phase and tetragonal phase.

[0039] Such as image 3 Shown in line c in the middle, it is the ZrO prepared by the implementation of the present invention 2 The UV-Vis absorption spectrum of the prepared ZrO 2 It hardly absorbs visible light, and only has certain absorption ability in the ultraviolet range.

Embodiment 3

[0041] Weigh 5g of melamine and 2.5g of zirconium nitrate (mass ratio, melamine: zirconium nitrate = 2:1) and place in a crucible, cover tightly and place in a muffle furnace for calcination, the calcination temperature is 550°C, the calcination time is 5h, room temperature Take out to get the initial tetragonal ZrO 2 Nanoparticle-regulated layered g-C 3 N 4 , and then, the sample was fully washed with deionized water, centrifuged, and dried to obtain the tetragonal ZrO 2 Nanoparticle-regulated layered g-C 3 N 4 Final sample of photocatalyst material.

[0042] Such as figure 2 Shown in the b line in the middle, it is the tetragonal phase ZrO prepared by the implementation of the present invention 2 Nanoparticle-modified layered g-C 3 N 4 The XRD picture shows that the directly obtained sample contains layered g-C 3 N 4 and ZrO 2 nanoparticles, and basically only tetragonal ZrO 2 .

[0043] Such as image 3 Shown in a line in the middle, prepare tetragonal phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com