Isosorbide plasticizer and preparation method and application thereof

A technology of isosorbide ester and plasticizer, applied in the field of isosorbide ester plasticizer and preparation thereof, can solve the problem of high price, and achieve the effects of reducing production cost, improving plasticity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

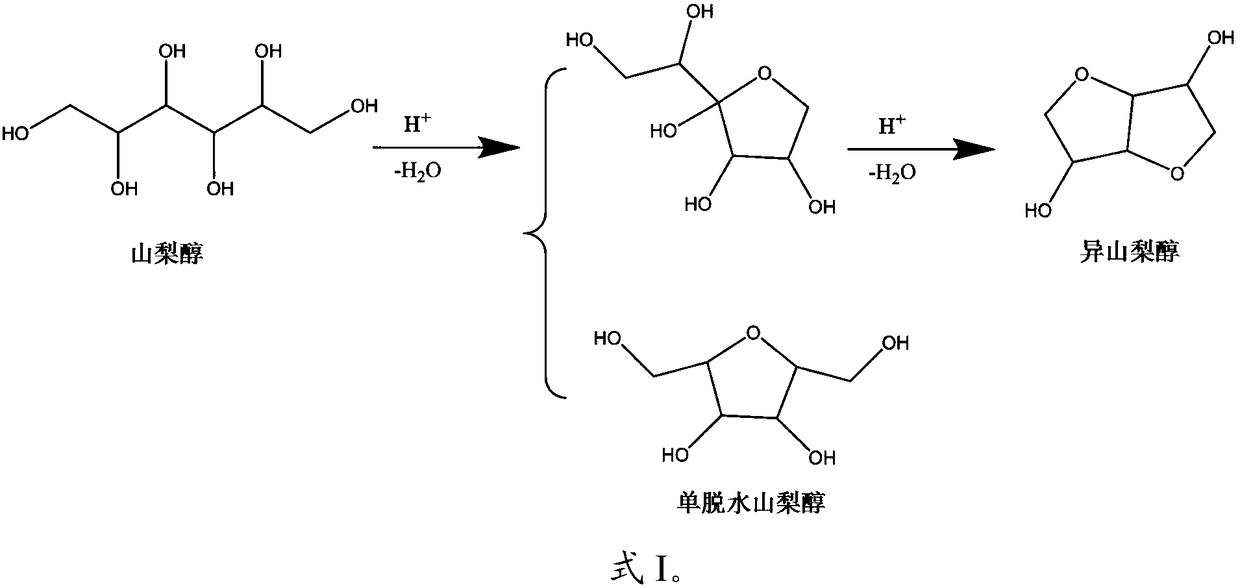

[0021] The invention provides a kind of preparation method of isosorbide plasticizer, comprises the following steps:

[0022] (1) dehydrating sorbitol under the action of an acidic catalyst to obtain sorbitan; the temperature of the dehydrating reaction is 60-180° C.;

[0023] (2) mix the sorbitan and fatty acid that described step (1) obtains, carry out esterification reaction under the effect of acidic catalyst, then carry out neutralization treatment to the product of described esterification reaction, obtain isosorbide ester plasticized agent; the temperature of the esterification reaction is 100~180°C;

[0024] The acid catalyst in the step (1) and step (2) is independently sulfuric acid, phosphoric acid, trifluoromethanesulfonic acid, trifluoroacetic acid, sulfamic acid or p-toluenesulfonic acid.

[0025] In the present invention, unless otherwise specified, each raw material component is a commercially available product well known to those skilled in the art.

[0026]...

Embodiment 1

[0064] 365 g of sorbitol were placed in a 1 L reactor equipped with a constant temperature heating mantle, stirring paddles, thermometer, condenser and distillation receiver.

[0065] Open stirring system and open heating system by 300rpm, when reactor temperature reaches 140 ℃, add the mass concentration of 1.5g and be the sulfuric acid of 98%, wherein the mass ratio of sorbitol and the vitriol oil is 100:0.4, then the heating mantle The temperature was set at 140 °C and the rotation speed was maintained at 500 rpm, the mounted assembly was connected to a vacuum pump equipped with a vacuum gauge, and its pressure was set at 0.01 MPa.

[0066] When the temperature of the reactor was raised to 140° C., the water generated by the dehydration reaction was distilled off and collected in a receiver, and the reaction was continued for 6 hours.

[0067] Then cool the reactor to 30°C, add 576g of n-octanoic acid, start the stirring and heating system, when the temperature reaches 60°C...

Embodiment 2

[0071] 365 g of sorbitol were placed in a 1 L reactor equipped with a constant temperature heating mantle, stirring paddles, thermometer, condenser and distillation receiver.

[0072] Open stirring system and open heating system by 300rpm, when reactor temperature reaches 70 ℃, add the mass concentration of 1.5g and be the sulfuric acid of 98%, wherein the mass ratio of sorbitol and the vitriol oil is 100:0.4, then the heating mantle The temperature was set at 140 °C and the rotation speed was maintained at 500 rpm, the mounted assembly was connected to a vacuum pump equipped with a vacuum gauge, and its pressure was set at 0.01 MPa.

[0073] When the temperature of the reactor was raised to 140° C., the water of the dehydration reaction was distilled off and collected in a receiver, and the reaction was continued for 6 hours.

[0074] Then the reactor was cooled to 30°C, and 688g of n-decanoic acid was added, and the stirring system was turned on. When the contents of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com