Polyester aqueous dispersion for painting in automobile and preparation method thereof

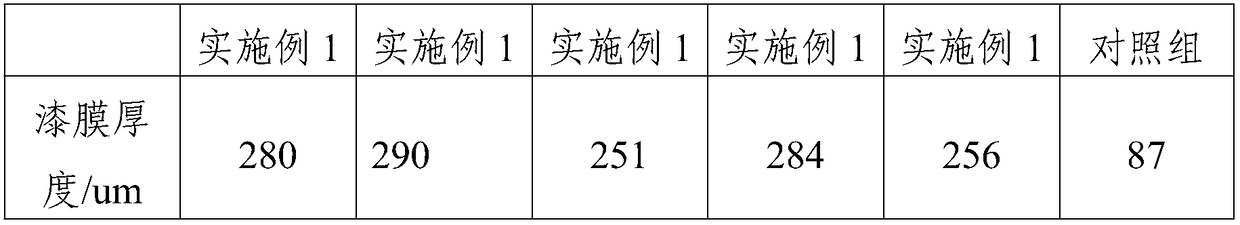

A technology of dispersion and polyester, which is applied in the field of polyester water dispersion system, can solve the problems of low viscosity, low force, and low toughness of paint, and achieve the effect of large paint film thickness, sufficient toughness, and not easy to foam and crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The invention provides an aqueous polyester dispersion used as a paint for automobiles. The aqueous polyester dispersion consists of the following components in parts by weight: 5-10 parts of modified polyacrylic acid and 1-3 parts of water.

[0022] Wherein, as the preparation method of the polyester aqueous dispersion of paint in the automobile comprises the steps,

[0023] (1) Put tert-butyl acrylate, distilled water, sodium hydroxide and emulsifier into a four-necked flask, then respectively install a thermometer, a stirrer, and a reflux condenser in the four-necked flask, and keep one mouthful to stop it with a wooden stopper Feeding tube; the mass ratio of tert-butyl acrylate, distilled water, sodium hydroxide and emulsifier is 50:20:10:5;

[0024] (2) Turn on the stirrer and keep the mixed solution hydrolyzed and emulsified at room temperature for 1.5h;

[0025] (3) Add potassium persulfate to the emulsion in step (2), the mass ratio of potassium persulfate and ...

Embodiment 2

[0031] The invention provides an aqueous polyester dispersion used as a paint for automobiles. The aqueous polyester dispersion consists of the following components in parts by weight: 5-10 parts of modified polyacrylic acid and 1-3 parts of water.

[0032] Wherein, as the preparation method of the polyester aqueous dispersion of paint in the automobile comprises the steps,

[0033] (1) Put tert-butyl acrylate, distilled water, sodium hydroxide and emulsifier into a four-necked flask, then respectively install a thermometer, a stirrer, and a reflux condenser in the four-necked flask, and keep one mouthful to stop it with a wooden stopper Feeding tube; the mass ratio of tert-butyl acrylate, distilled water, sodium hydroxide and emulsifier is 60:30:15:8;

[0034] (2) Turn on the stirrer and keep the mixed solution hydrolyzed and emulsified at room temperature for 1.5h;

[0035] (3) Add potassium persulfate to the emulsion in step (2), the mass ratio of potassium persulfate and ...

Embodiment 3

[0041] The invention provides an aqueous polyester dispersion used as a paint for automobiles. The aqueous polyester dispersion consists of the following components in parts by weight: 5-10 parts of modified polyacrylic acid and 1-3 parts of water.

[0042] Wherein, as the preparation method of the polyester aqueous dispersion of paint in the automobile comprises the steps,

[0043] (1) Put tert-butyl acrylate, distilled water, sodium hydroxide and emulsifier into a four-necked flask, then respectively install a thermometer, a stirrer, and a reflux condenser in the four-necked flask, and keep one mouthful to stop it with a wooden stopper Feeding tube; the mass ratio of tert-butyl acrylate, distilled water, sodium hydroxide and emulsifier is 52:22:11:6;

[0044] (2) Turn on the stirrer and keep the mixed solution hydrolyzed and emulsified at room temperature for 1.5h;

[0045] (3) Add potassium persulfate to the emulsion in step (2), the mass ratio of potassium persulfate and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap