Low-formaldehyde adhesive and application thereof to production of solid wood composite floors

An adhesive and low-aldehyde technology, applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of low solid content, long production cycle, poor fluidity, etc., and achieve low formaldehyde emission , Formaldehyde emission reduction, the effect of reducing formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

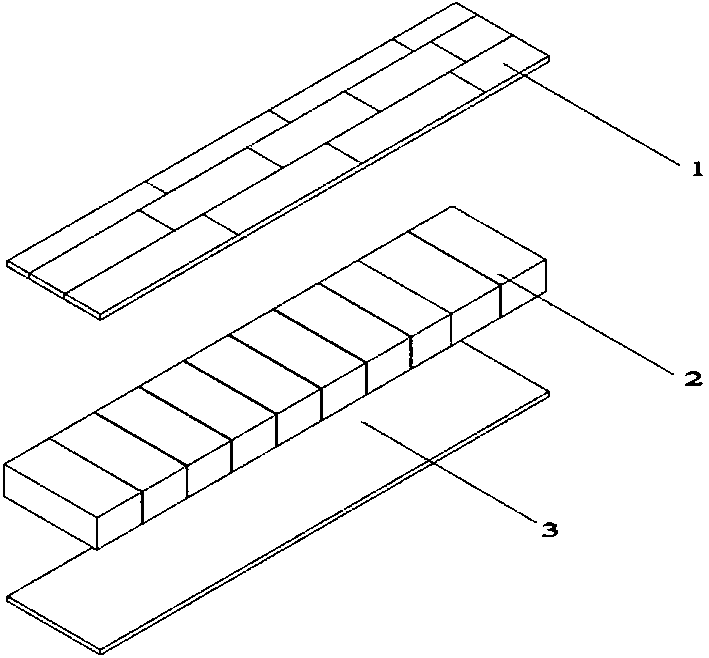

Image

Examples

Embodiment 1

[0040] A low-aldehyde adhesive, which is composed of ingredients GP and ingredients HP, mixed according to the mass ratio of 90-110:15-25, wherein:

[0041] The composition of described batching GP is:

[0042] New 4405 90-100 parts by mass,

[0043] 194C or 5915 20-30 parts by mass,

[0044] 4865 15-25 parts by mass,

[0045] 50-60 parts by mass of water;

[0046] The composition of the ingredient HP is 172C, and the parts by mass are 15-25 parts.

Embodiment 2

[0048] The low aldehyde adhesive that embodiment 1 is made is applied to the production of parquet, comprises the steps:

[0049] A. Prepare the surface board: select ebony wood, saw, sort and process it into sheets, and dry it in a conventional kiln, with a moisture content of 6.5 ± 0.6%;

[0050] B, prepare core board: select fish scale pine for use, routine drying, moisture content reaches 7.5 ± 1.6%;

[0051] C, prepare the backboard: select sylvestris sylvestris for use, utilize conventional kiln drying, make the backboard moisture content be 6.5 ± 1.0%, make the bottom board of required thickness and width through sanding, shearing;

[0052] D, gluing: select the low aldehyde glue that embodiment 1 makes for use, coat adhesive on the gluing surface of well-balanced table board and back board, described ebony wood coating amount 160 ± 5 g / m 2 , coating amount of back plate 140±5 g / m 2 ;

[0053] E. Blank assembly and hot pressing: Arrange the front panel, core panel an...

Embodiment 3

[0061] The surface board is made of three-piece ebony wood, the core board is made of fish-scale pine, and the back board is made of sylvestris pine. The low-aldehyde glue was prepared, and the coating amount of the surface and the back plate were 162 g / m² and 161 g / m², respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com