A special synthetic processing fluid for tantalum plates and its preparation method

A processing fluid and oil-soluble technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of low yield, ear making, orange peel, etc., and achieve the effects of convenient operation, environmentally friendly working environment, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

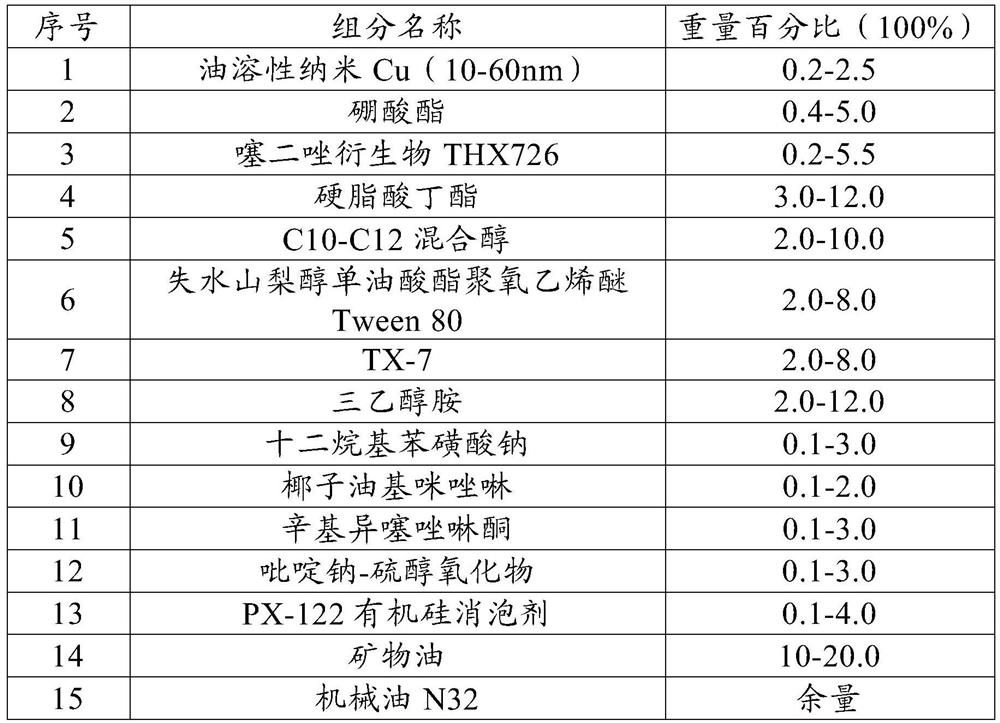

[0012] Embodiment 1 formula sees the following table:

[0013] serial number component name Weight percent (100%) 1 Oil-soluble nano-Cu (10-60nm) 2 2 Borate 4 3 Thiadiazole derivative THX726 2 4 Butyl stearate 30 5 C10-C12 mixed alcohol 30 6 Sorbitan Monooleate Polyoxyethylene Ether Tween 80 20 7 TX-7 20 8 Triethanolamine 20 9 Sodium dodecyl benzene sulfonate 3 10 Coco imidazoline 3 11 Octylisothiazolinone 3 12 Sodium pyridinium-thiol oxide 3 13 PX-122 silicone defoamer 3 14 mineral oil 120 15 Machine oil N32 738

[0014] Production method: According to the weight formula of each component in the above table, first put 120kg of mineral oil and 738kg of mechanical oil N32 into the reaction kettle with a rotation speed of 50-120 rpm for heating and stirring, when the temperature reaches 60-80°C, then sequentially 2kg oil-soluble nano Cu (10-60nm), 4kg borate e...

Embodiment 2

[0016] Production method is with embodiment 1, and component name and percentage by weight thereof are shown in the following table:

[0017] serial number component name Weight percent (100%) 1 Oil-soluble nano-Cu (10-60nm) 10 2 Borate 20 3 Thiadiazole derivative THX726 30 4 Butyl stearate 60 5 C10-C12 mixed alcohol 80 6 Sorbitan Monooleate Polyoxyethylene Ether Tween 80 50 7 TX-7 40 8 Triethanolamine 80 9 Sodium dodecyl benzene sulfonate 20 10 Coco imidazoline 15 11 Octylisothiazolinone 30 12 Sodium pyridinium-thiol oxide 30 13 PX-122 silicone defoamer 25 14 mineral oil 150 15 Machine oil N32 360

[0018] Production method: According to the weight formula of each component in the above table, first put 150kg of mineral oil and 360kg of mechanical oil N32 into the reaction kettle with a rotation speed of 50-120 rpm for heating and stirring, when the temperat...

Embodiment 3

[0020] Embodiment 3 formula sees the following table:

[0021] serial number component name Weight percent (100%) 1 Oil-soluble nano-Cu (10-60nm) 15 2 Borate 30 3 Thiadiazole derivative THX726 45 4 Butyl stearate 100 5 C10-C12 mixed alcohol 80 6 Sorbitan Monooleate Polyoxyethylene Ether Tween 80 60 7 TX-7 60 8 Triethanolamine 100 9 Sodium dodecyl benzene sulfonate 30 10 Coco imidazoline 20 11 Octylisothiazolinone 30 12 Sodium pyridinium-thiol oxide 30 13 PX-122 silicone defoamer 40 14 mineral oil 180 15 Machine oil N32 170

[0022] Production method: According to the weight formula of each component in the above table, first put 180kg of mineral oil and 170kg of mechanical oil N32 into the reaction kettle with a rotation speed of 50-120 rpm for heating and stirring, when the temperature reaches 60-80°C, then sequentially 15kg oil-soluble nano Cu (10-60nm), 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com