A kind of electrochemical preparation method of alkenyl sulfone compound

A compound, alkenyl sulfone technology, applied in the field of electrochemical preparation of alkenyl sulfone compounds, can solve the problems of harsh conditions, unfriendly environment, complex method conditions, etc., and achieves the effects of high yield, simple and efficient reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] With reticular glassy carbon (RVC electrode) as the anode and metal platinum as the cathode, add 1.0mmol NH 4 ClO 4 , 0.3mmolβ-bromostyrene, 0.9mmol sodium p-toluenesulfinate, 5mL NMP, 1mL H 2 O. Magnetic stirrer, cover the lid, turn on the power supply, adjust the current to 15mA, and electrolyze for 5h at room temperature. After the reaction, the crude product was extracted with ethyl acetate, the organic layers were combined, and anhydrous Na 2 SO 4 After drying and evaporating to dryness under reduced pressure, the corresponding product 3a was obtained after separation and purification, and the yield of product 3a was 86%.

[0032] The synthetic route of the present invention is as follows:

[0033]

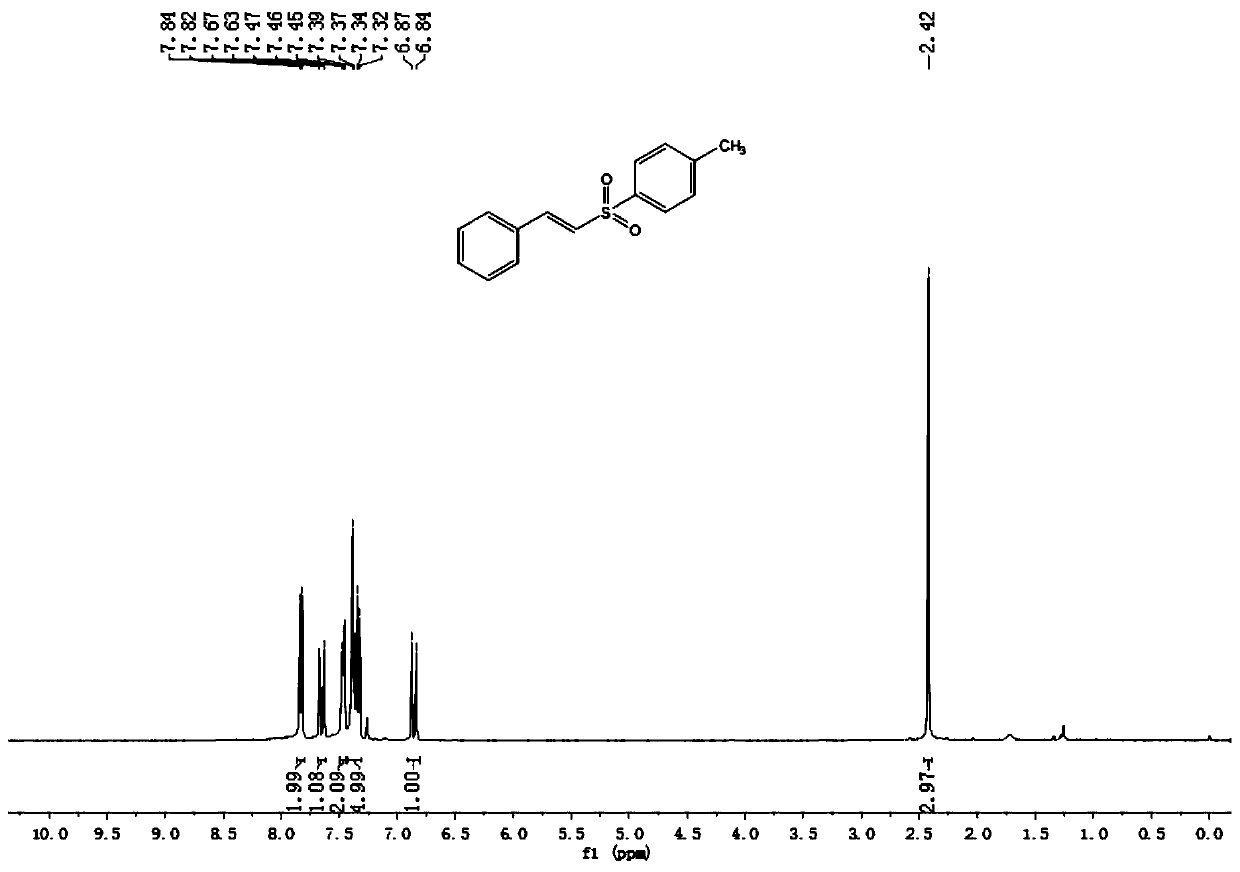

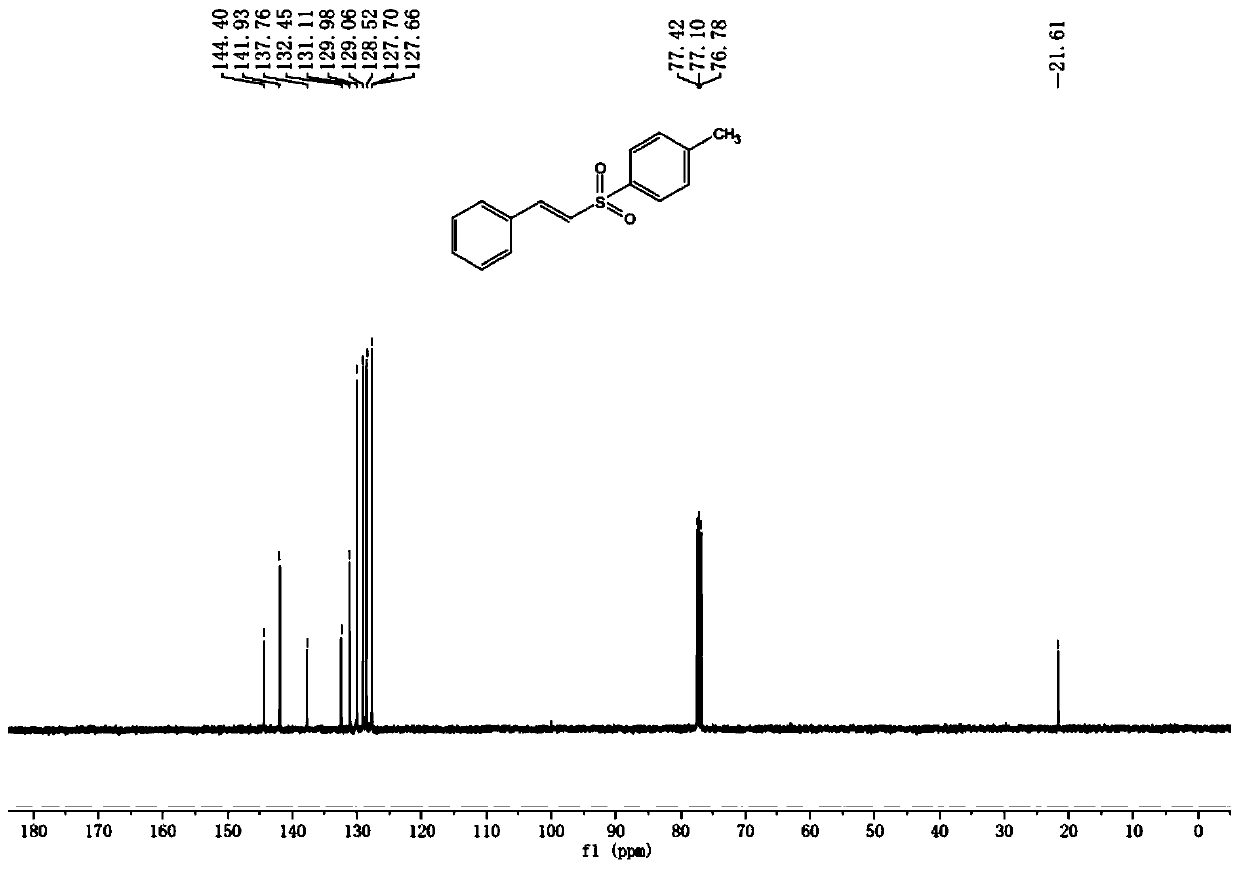

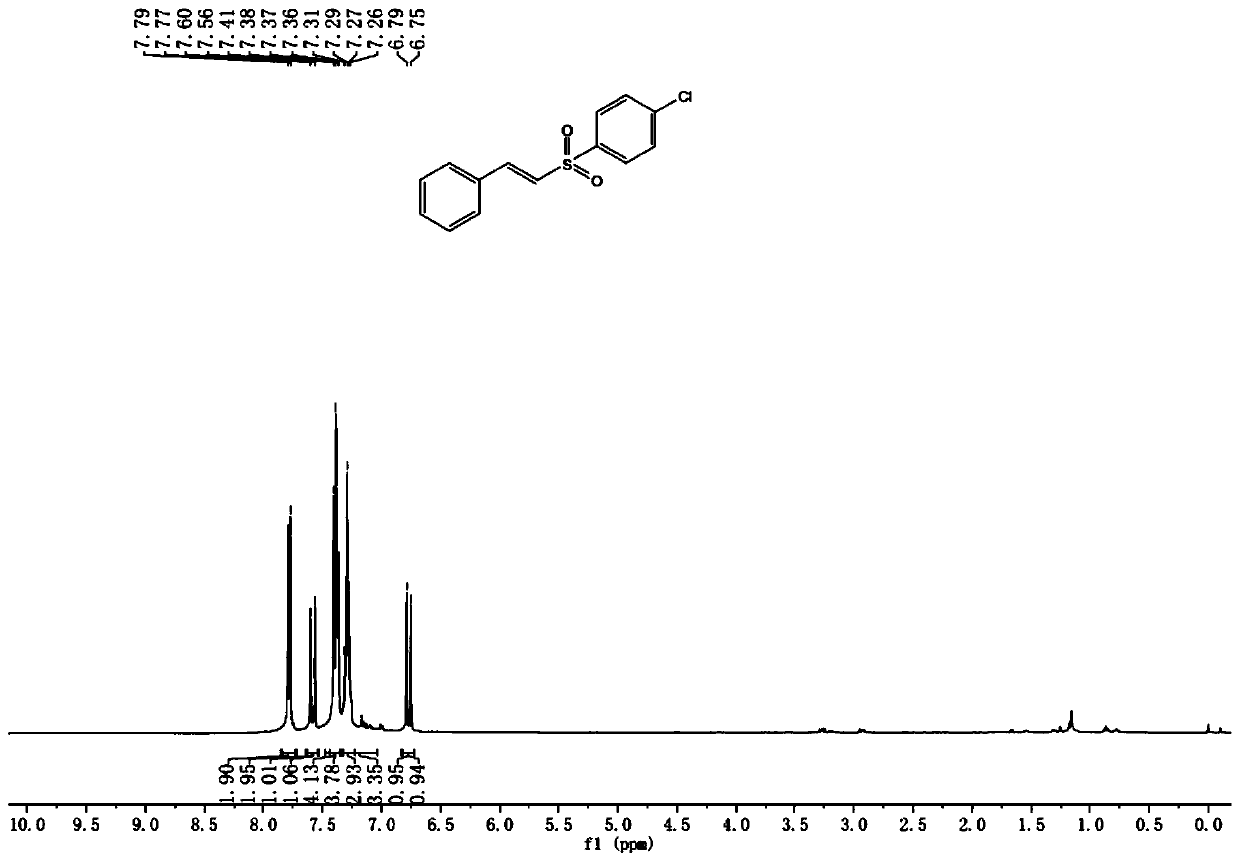

[0034] The resulting product results from 1 H NMR, 13 Confirmed by C NMR

[0035] Analysis of the product structure obtained in Example 1, the above results and the literature reported by Rueping et al. [Yue, H.-F.Zhu, C.Rueping, M.Angew.Chem.Int.Ed. In cont...

Embodiment 2

[0042] With metallic platinum as the anode and reticular glassy carbon (RVC electrode) as the cathode, add 1.0 mmol NH in turn to the round bottom flask 4 ClO 4 , 0.3mmolβ-bromostyrene, 0.9mmol sodium p-toluenesulfinate, 5mL NMP, 1mL H 2 O. Magnetic stirrer, cover the lid, turn on the power supply, adjust the current to 15mA, and electrolyze for 5h at room temperature. The crude product was extracted with ethyl acetate, the organic layers were combined, anhydrous Na 2 SO 4After drying and evaporating to dryness under reduced pressure, the corresponding product 3a was obtained after separation and purification, and the yield of product 3a was 60%.

Embodiment 3

[0044] With reticular glassy carbon (RVC electrode) as the anode and metal platinum as the cathode, add 1.0mmol NH 4 ClO 4 , 0.3mmolβ-bromostyrene, 0.9mmol sodium p-toluenesulfinate, 5mL NMP, 1mL H 2 O. Magnetic stirrer, cover the lid, turn on the power, adjust the current to 10mA or 20mA respectively, and the electrolysis time at room temperature is 6h or 4h respectively. The crude product was extracted with ethyl acetate, the organic layers were combined, anhydrous Na 2 SO 4 After drying, evaporation under reduced pressure, the corresponding product 3a was obtained after separation and purification, and the yields of product 3a were 75% (10mA, 6h) or 71% (20mA, 4h), respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com