Method for realizing co-production of anaerobic biogas production and aerobic fertilizer production of agricultural wastes

A technology of agricultural waste and aerobic fermentation, which is applied in the field of organic waste resource treatment, can solve the problems of difficult heat collection, time-consuming and labor-intensive raw material transfer, and large floor area, so as to save land occupation and construction costs, and eliminate stirring The effect of dead angle and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0027] In each of the following embodiments or examples, if there are no specially specified raw materials, it means that they are all conventional commercially available products in this field; if there are no specially specified functional parts or structures, it means that they are all used in this field to realize corresponding functions. Instead, conventional components or conventional structures are used.

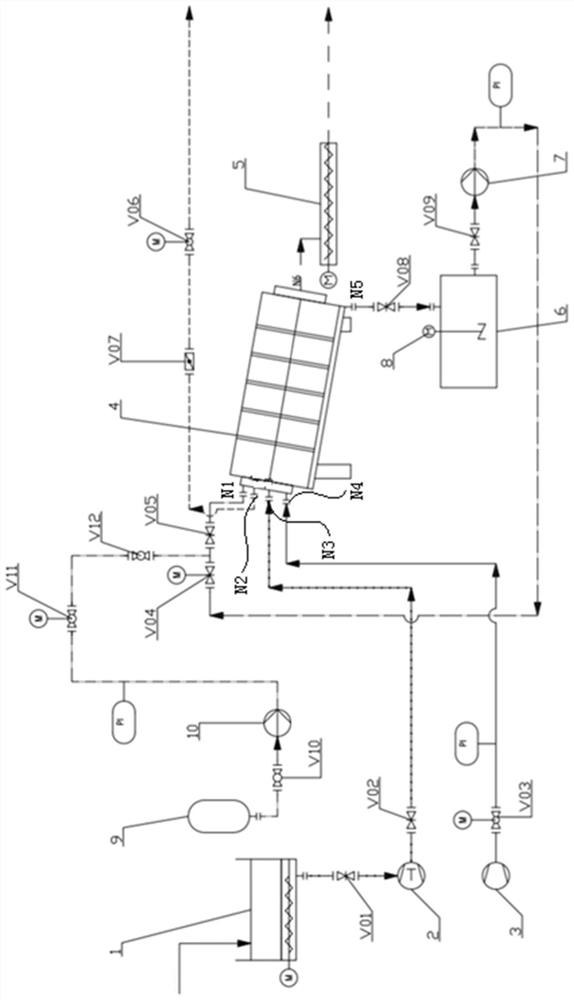

[0028] The purpose of the present invention is to provide a method for realizing the joint production of anaerobic biogas production and aerobic fertilizer production of agri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com