Flexible supporting mechanism with vibration and thermal insulation and deformation absorbing functions

A support mechanism and functional technology, applied in the field of flexible support mechanism, can solve the problems of rising ambient temperature, increased rotor wear, and reduced viscosity of lubricating oil, etc., to achieve the effect of improving service life and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution is described in detail with reference to the drawings and embodiments.

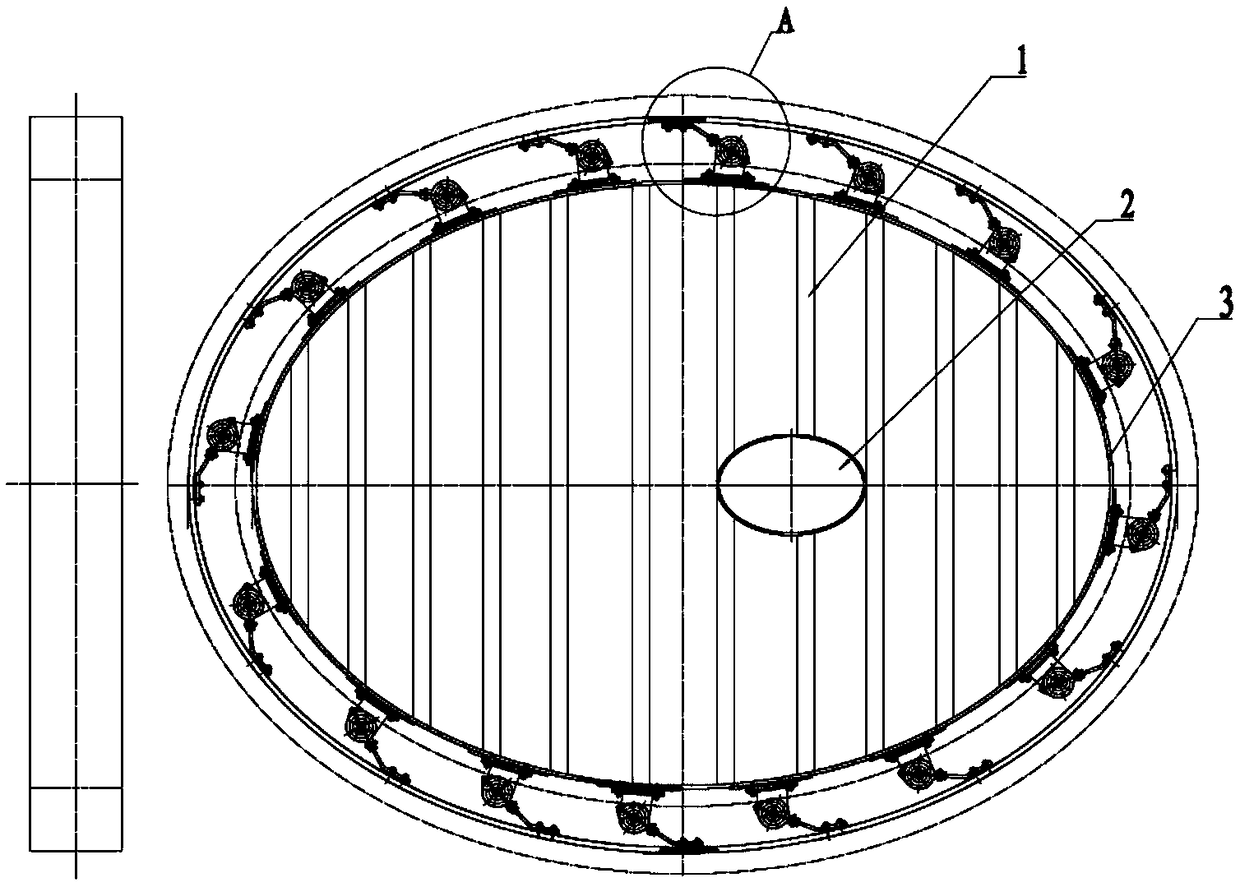

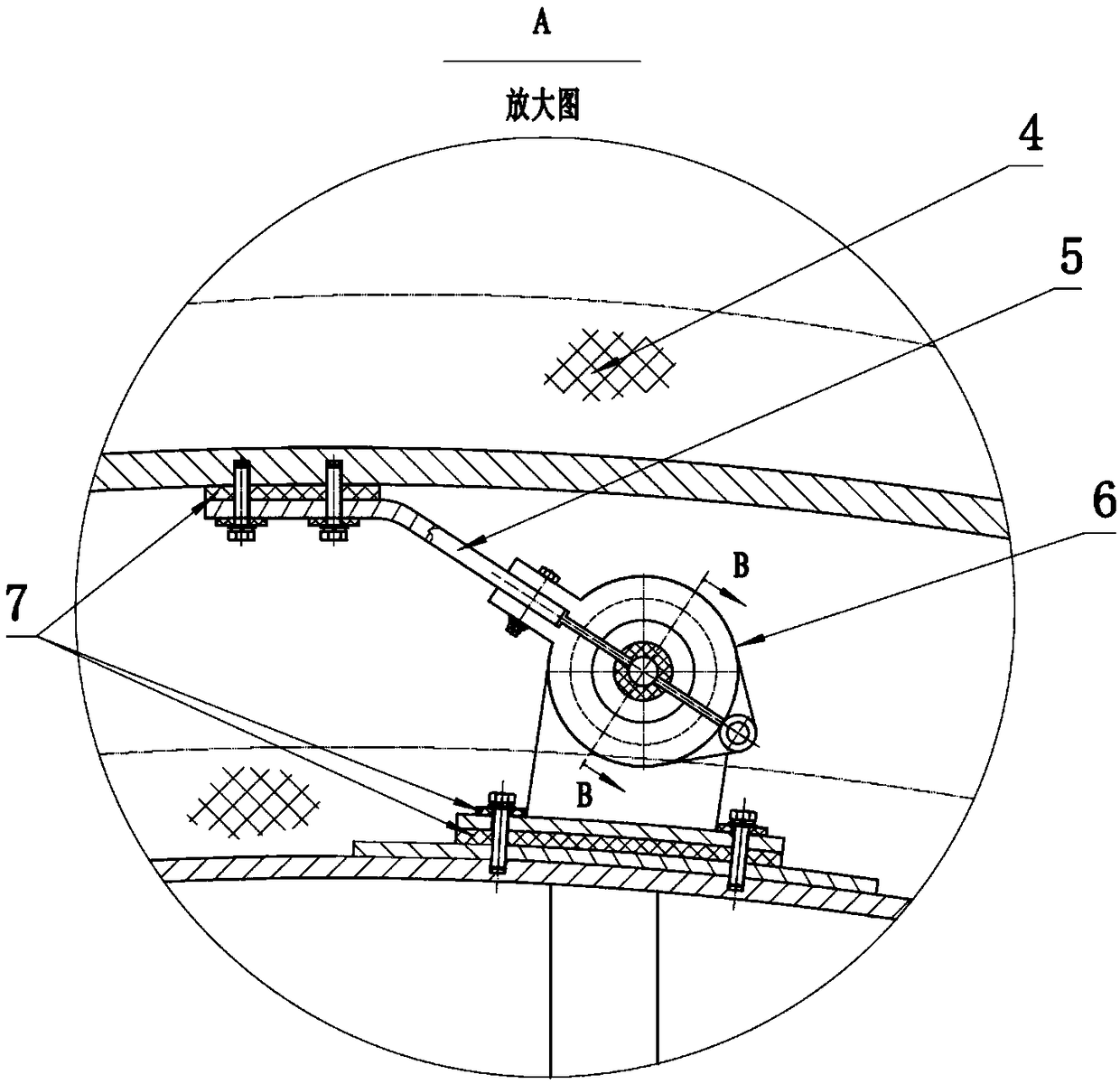

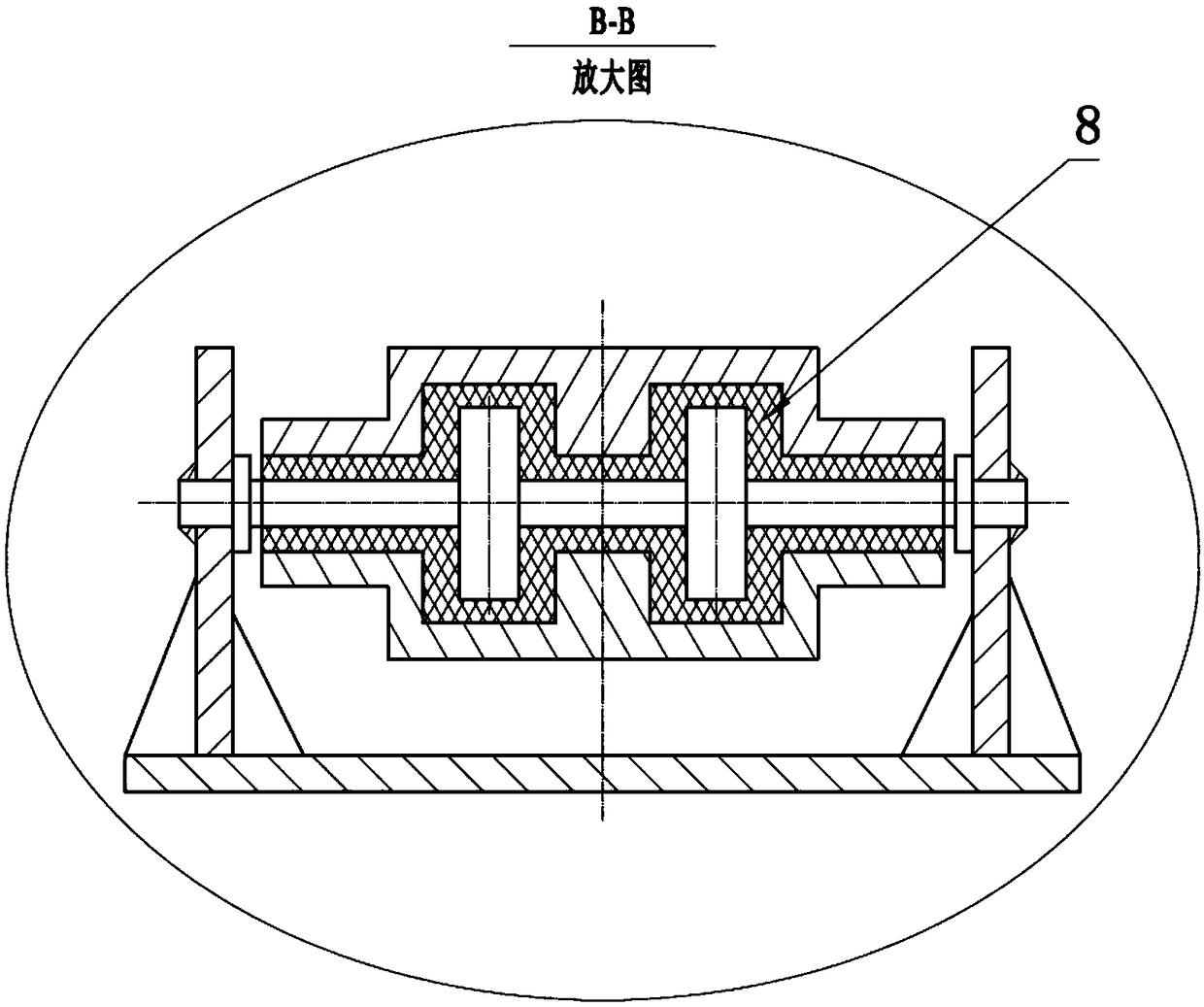

[0023] The main compressor is arranged between the first and second corner sections, and the long axis driven by the compressor passes through the supporting structure by cooperating with the shaft sleeve 2; the deflector 1 is circularly supported on the inner wall of the cave. When passing through the air duct, the deflector 1 will change the direction of the airflow to continue to move forward; the flexible support frame A is distributed between the inner wall 3 and the outer wall of the cave, and is connected with the inner wall 3 of the cave by bolts, and heat insulating pads are used at each joint Sheet 7 can be made of low-temperature-resistant materials such as special polytetrafluoroethylene, which can avoid the effects of low compressor efficiency caused by unsatisfactory lubricating effect. In addition, this heat-insulating gasket 7 has both pressure-resistant and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com