Rapid evaluation method for compaction uniformity of asphalt mixture

A technology of asphalt mixture and evaluation method, applied in the direction of material weighing, analyzing materials, weighing by removing certain components, etc., can solve the problem of high price, achieve the effect of rapid prediction and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

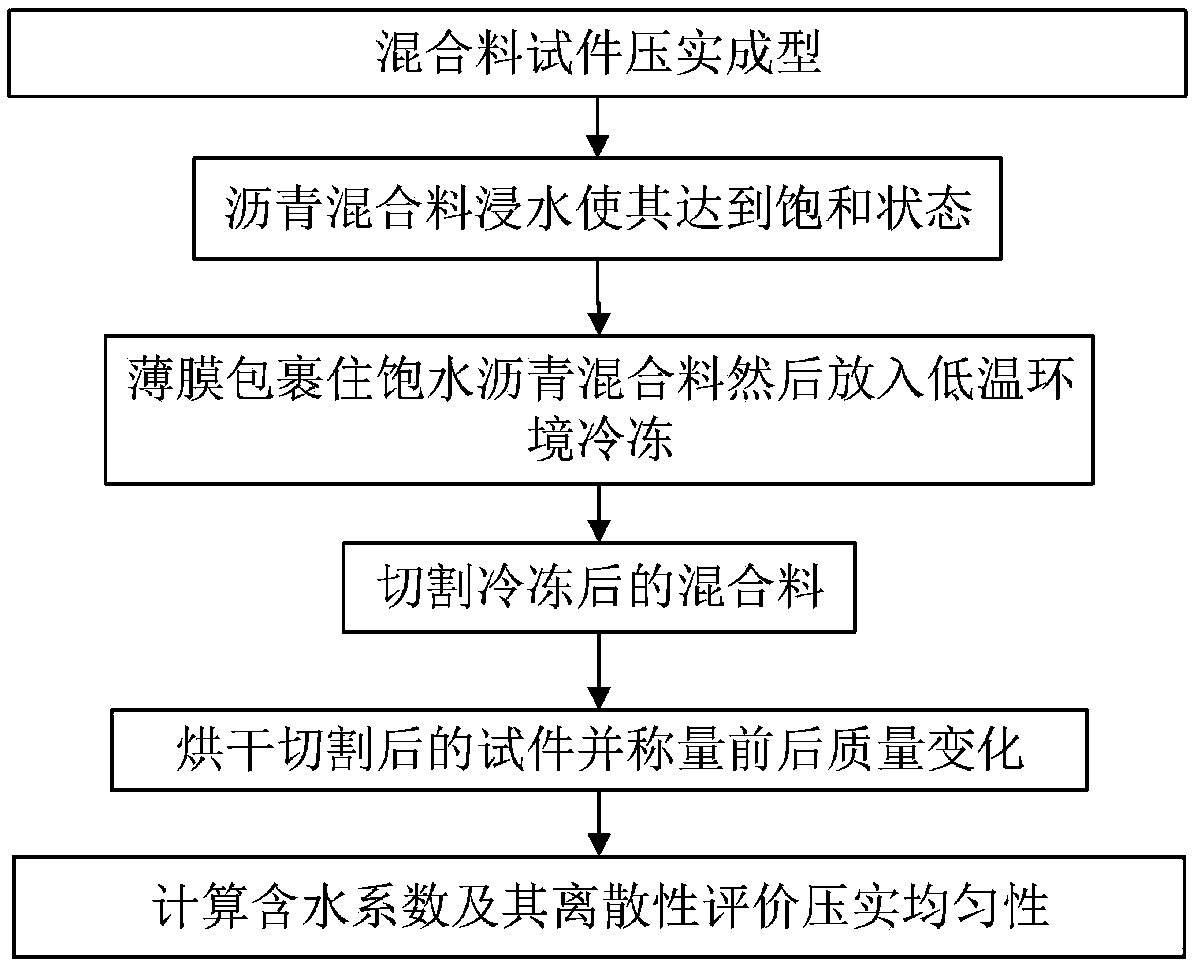

[0014] Specific embodiment one: In this embodiment, a rapid evaluation method for the compaction uniformity of asphalt mixture is carried out according to the following steps:

[0015] 1. According to the construction needs, select asphalt and aggregate to mix according to the design of the mix ratio, and then compact the mixture to obtain the asphalt mixture test piece;

[0016] 2. Immerse the asphalt mixture test piece in water, wrap the asphalt mixture with a film after it reaches the saturated state, take it out, and then transfer it to a low temperature environment for freezing to obtain the frozen asphalt mixture;

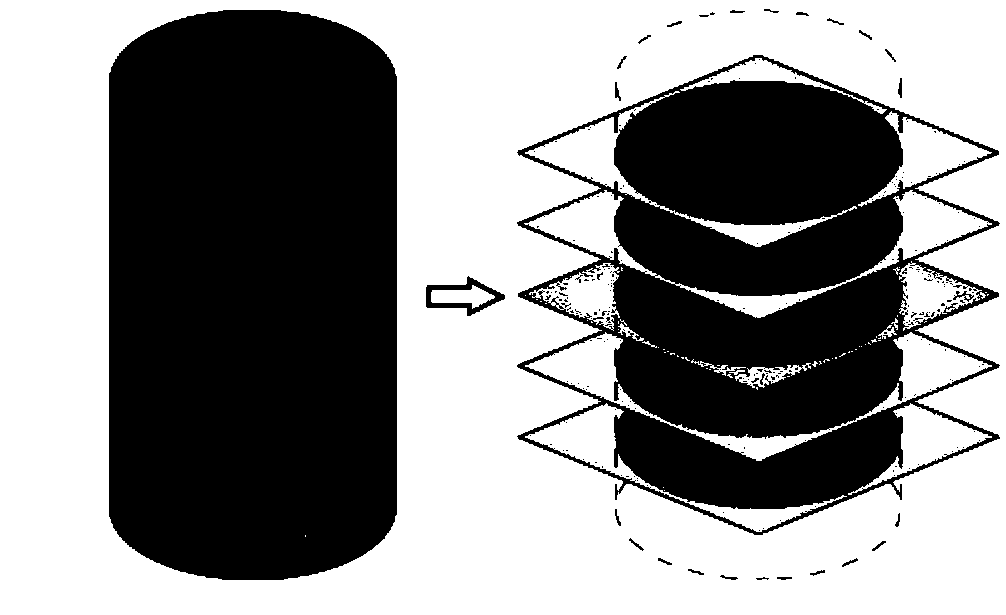

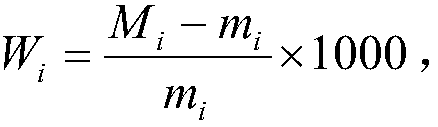

[0017] 3. Cut the frozen asphalt mixture into N small pieces to obtain N pieces of asphalt mixture. Weigh the mass of each single piece of asphalt mixture, then put it into the oven to a constant weight state, and record the constant weight. The quality of each individual asphalt mixture in the heavy state; calculate the water content coefficient of each indi...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the compaction described in Step 1 is the method of Marshall compaction, rotary compaction or shear compaction. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the low temperature environment described in Step 2 is -10°C. Others are the same as those in Embodiment 1 or 2.

[0022] In the freezing process of the asphalt mixture in this embodiment, damage phenomena such as low-temperature cracking of the mixture cannot occur.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com