Antipollution medical waste treatment device

A technology of medical waste and processing equipment, applied in the field of medical equipment, can solve the problems of excessive total number of bacteria and coliform value, damage to the surrounding environment of medical pollution, and inability to process medical waste, so as to achieve easy control, save labor costs, and prevent germs Diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

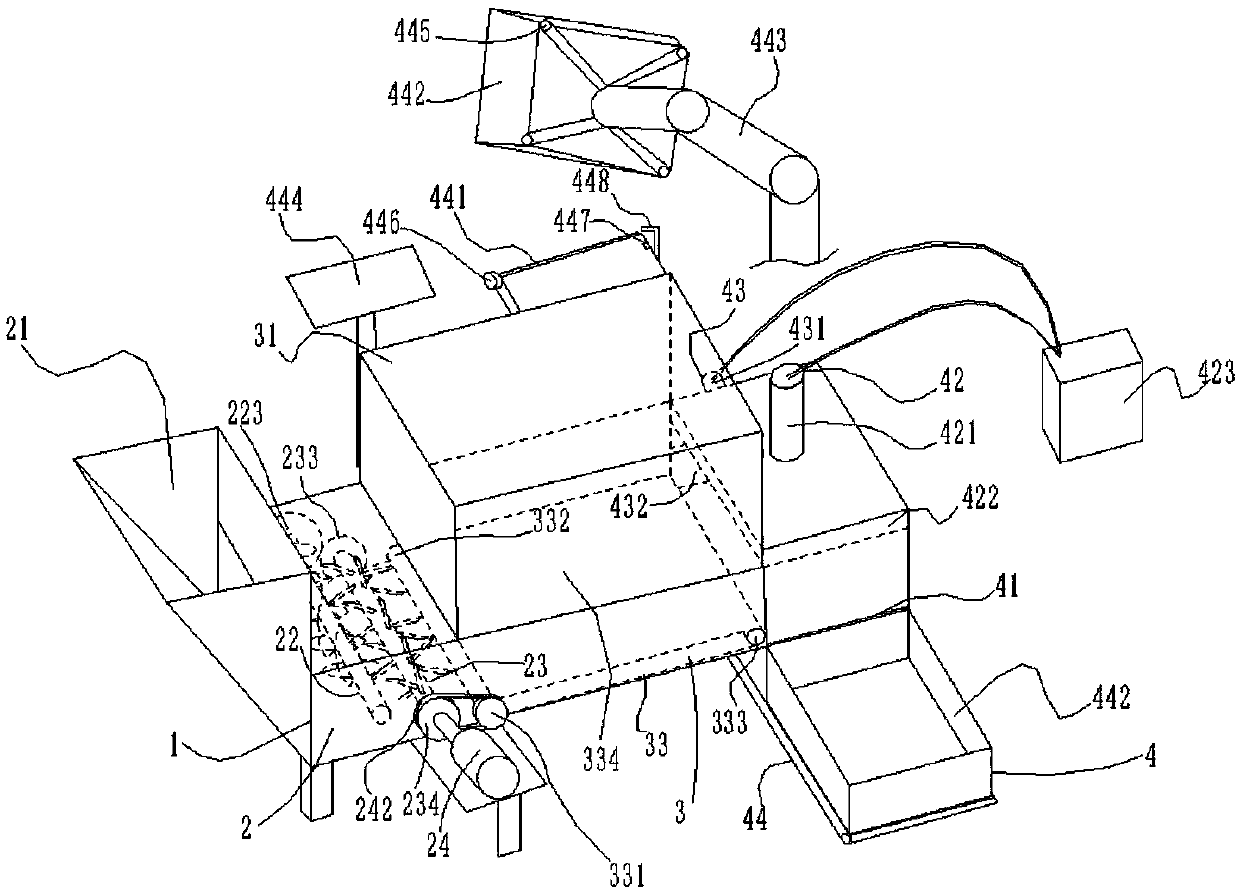

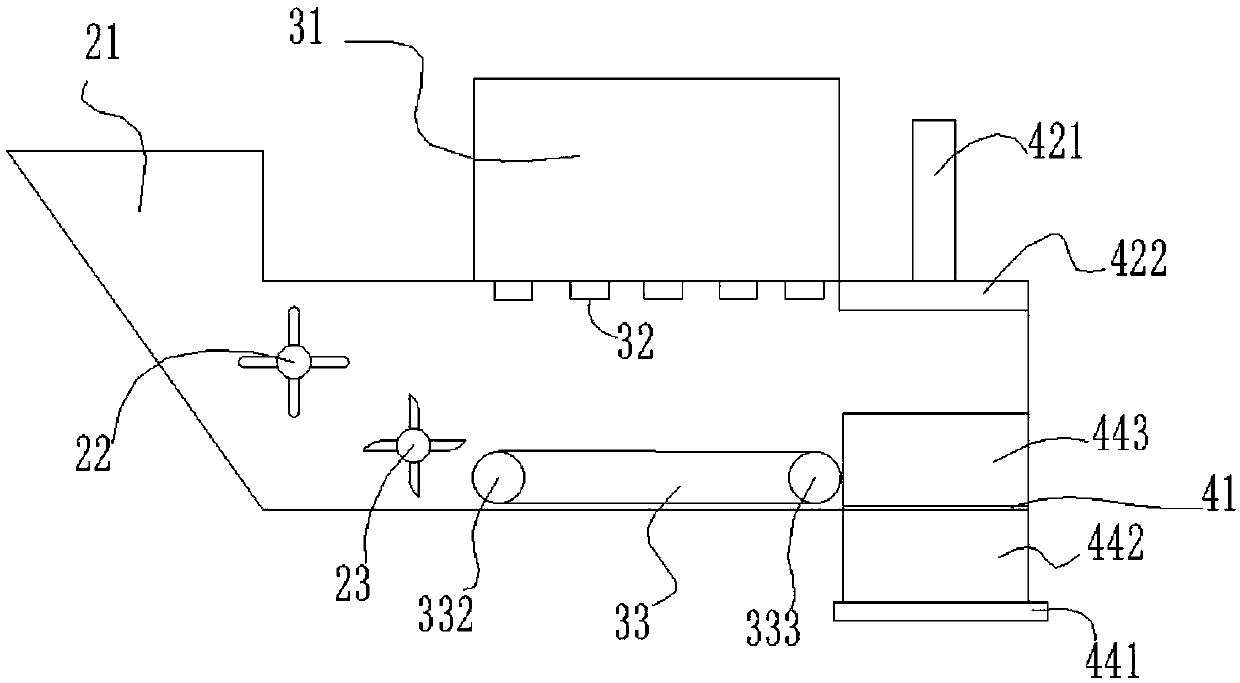

[0029] In order to facilitate the understanding of the technical solution of the present invention, the following combination Figure 1-3 For further explanation, the examples do not constitute a limitation to the protection scope of the present invention.

[0030] as attached figure 1 As shown, an anti-pollution medical waste treatment device includes a housing 1, a scrap unit 2, a disinfection unit 3, and a bagging unit 4, and the housing 1 is a channel with a rectangular cross section;

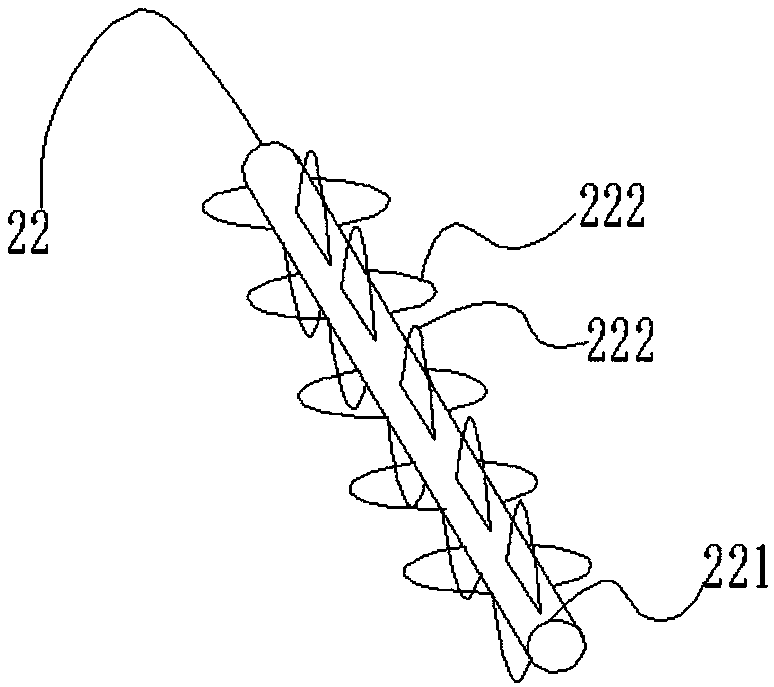

[0031] as attached figure 2As shown, the crushing unit 2 mainly includes a garbage input port 21, a coiling device 22, a crushing device 23, and a motor one 24. The garbage input port 21 is connected to the left port of the housing 1 and the opening is upward, and the coiling device 22 includes a shaft One 221, blade one 222, gear one 223, shaft one 221 is horizontal and vertically connected to the inner 2 / 3 height of housing 1, and is close to the garbage disposal port 21, blade one 222...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, the difference is:

[0040] Disinfectant includes by weight percentage: 0.25% triclosan, 0.16% sodium alkenyl sulfonate, 2.5% double chain quaternary ammonium salt, 14% dodecyl dimethyl benzyl ammonium chloride, 6% ethylene glycol , 10% isoprenyl, 6% isopropanol, 9% zinc acetate, and the balance is deionized water.

[0041] The push plate 432 is a metal plate with a height of 11 / 3 of the casing, and the thrust of the push plate 432 and the pressure of the pressure plate 422 are both 110N.

Embodiment 3

[0043] This embodiment is basically the same as Embodiment 1, the difference is:

[0044] Disinfectant includes by weight percentage: 0.3% triclosan, 0.17% sodium alkenyl sulfonate, 3% double chain quaternary ammonium salt, 15% dodecyl dimethyl benzyl ammonium chloride, 7% ethylene glycol , 12% isoprenyl, 0.7% isopropanol, 10% zinc acetate, and the balance is deionized water.

[0045] The push plate 432 is a metal plate with a height of 11 / 3 of the casing, and the thrust of the push plate 432 and the pressure of the pressure plate 422 are both 120N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com