Control method for asymmetrical fillet weld joint melting form and melting depth

A control method and fillet weld technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., to achieve the effect of avoiding unfused defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

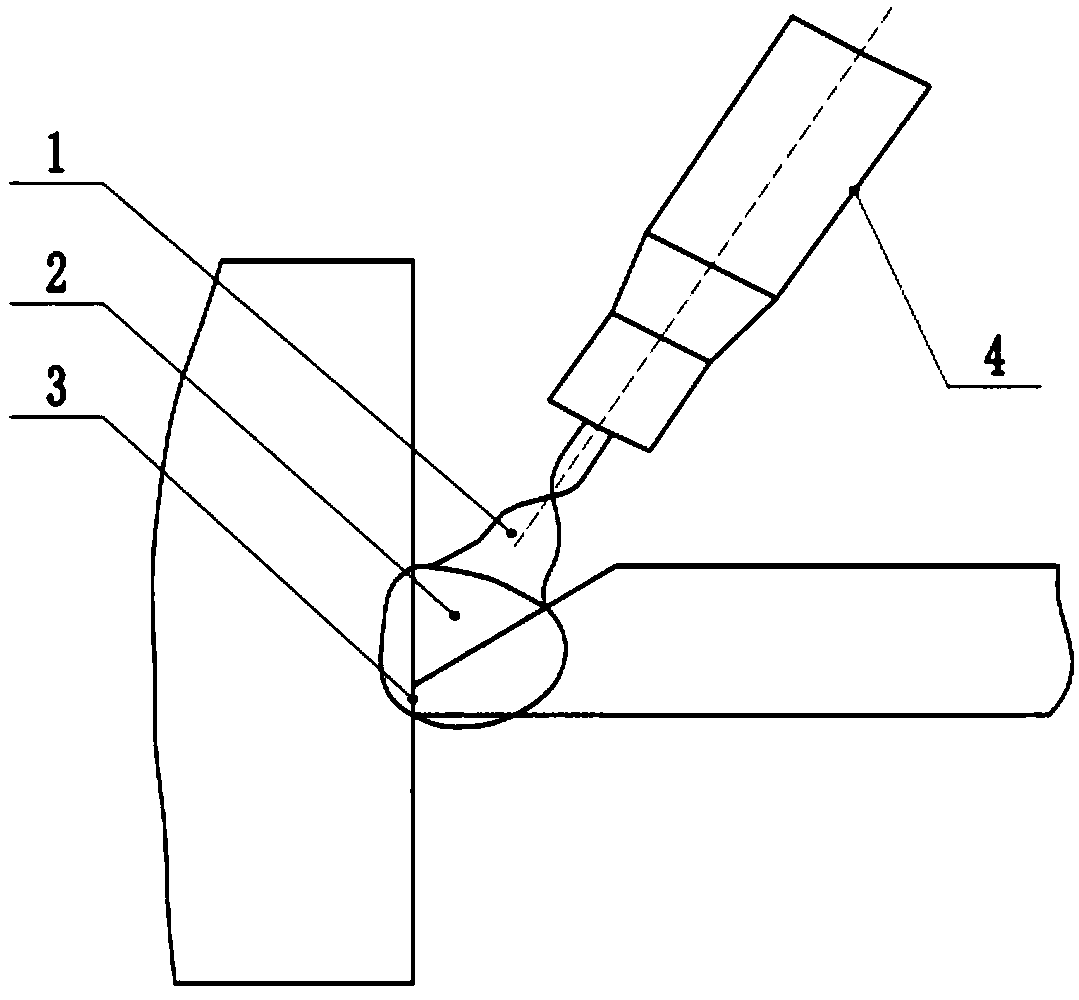

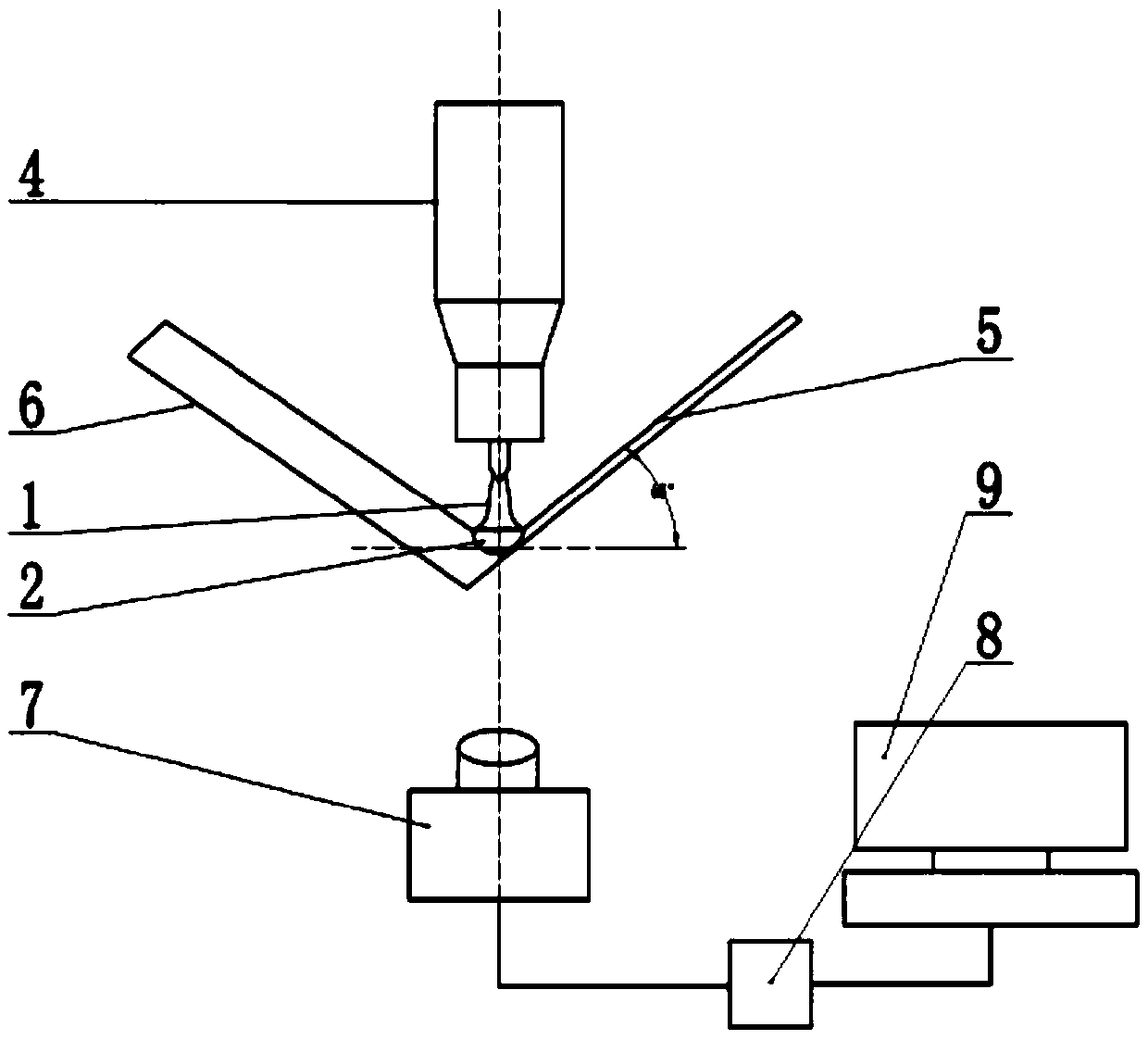

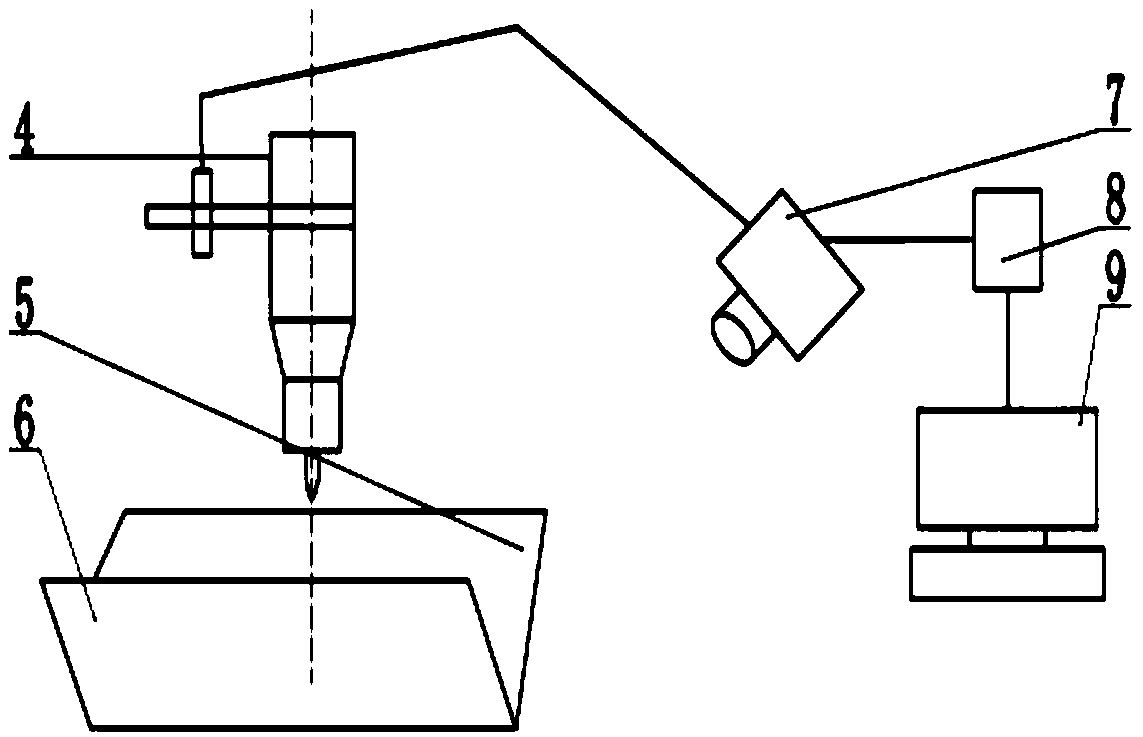

[0055] Such as Figure 1 to Figure 12 as shown,

[0056] Visual sensing system: It consists of XVC-G CCD camera produced by Canada Xiris, image acquisition card and narrow-band filter with a center wavelength of 650mm. The captured images are directly transferred to the computer via the power injector. The collected images are processed with matlab.

[0057] Test conditions: Times TDW4000 pulsed TIG welding machine was used in the asymmetric fillet weld welding test, the welding method was wire-filled TIG welding and the power frequency was 2Hz, the test material was Q235, the welding speed was 3mm / s, and the shielding gas was Ar; The size of the grooved plate is 170mm×50mm×6mm, and the size of the grooved plate is 170mm×50mm×6mm (60° groove, 2mm blunt edge); the angle β of the welding torch is set as the actual angle between the welding torch and one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com