Long glass fiber enhanced polypropylene composite material and preparation method thereof

A composite material and long glass fiber technology, which is applied in the field of long glass fiber reinforced polypropylene composite materials and its preparation, can solve problems such as damage and lack of strength, achieve reduced length breakage, reasonable formula, and improved wear resistance and impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

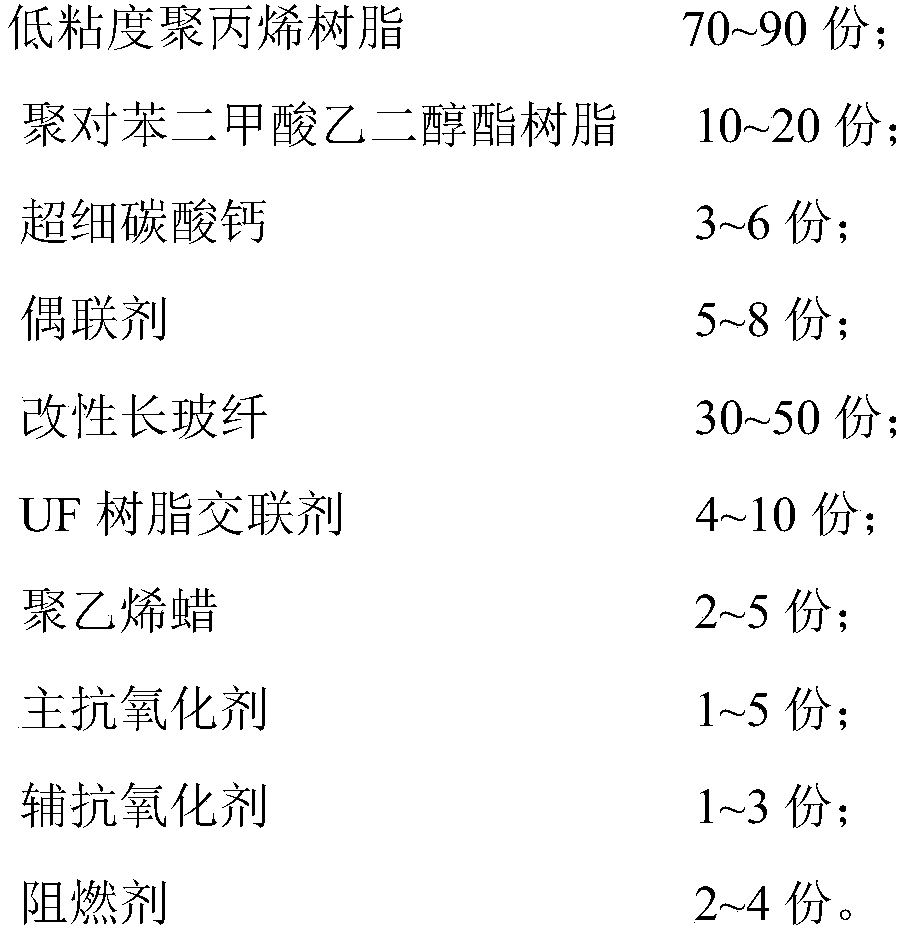

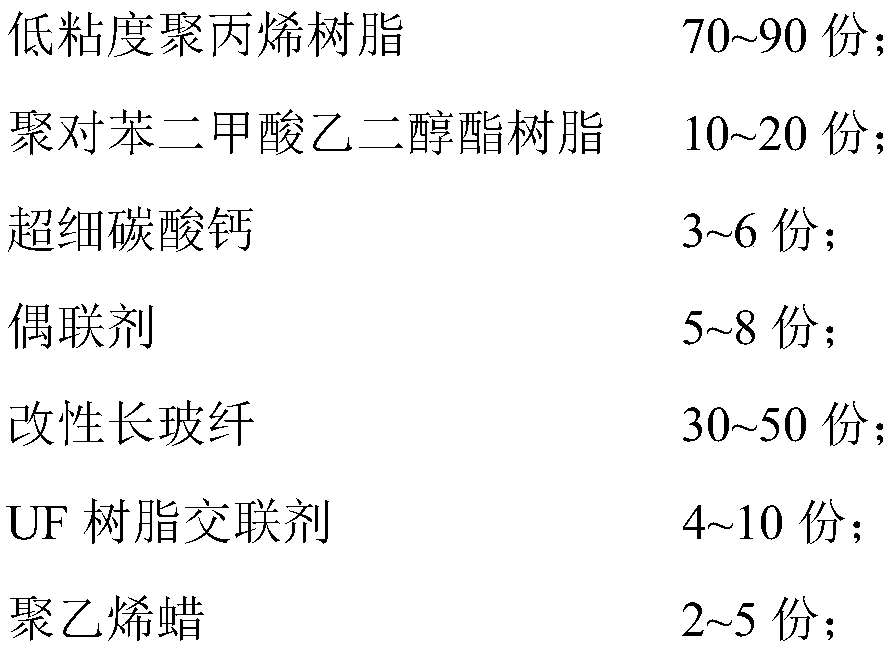

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Mix and stir 14 parts of polyethylene terephthalate resin, 5 parts of superfine calcium carbonate and 7 parts of coupling agent, raise the temperature to 70°C and keep it warm, add 85 parts of low-viscosity polypropylene resin and stir for 25 minutes, Then melt and extrude at 210°C through a plastic extruder, and obtain a modified polypropylene resin masterbatch after cooling and pelletizing; meanwhile, take 8 parts of nano-titanium dioxide, 42 parts of phenol, 27 parts of ethanol, 12 parts of triethanolamine and Mix 6 parts of oxalic acid to obtain the immersion liquid, mix the alkali-free glass fiber with the immersion liquid at a mass ratio of 5:10, and process the immersion liquid for 1.5 hours to obtain the modified long glass fiber;

[0028] Step 2: The modified polypropylene resin masterbatch obtained in step 1 is mixed with 6 parts of UF resin crosslinking agent, 3 parts of polyethylene wax, 4 parts of aromatic amine, 2 parts of phosphite and 3 parts of m...

Embodiment 2

[0031] Step 1: Mix and stir 10 parts of polyethylene terephthalate resin, 3 parts of superfine calcium carbonate and 5 parts of coupling agent, raise the temperature to 50°C and keep it warm, add 70 parts of low-viscosity polypropylene resin and stir for 20 minutes, Then melt and extrude through a plastic extruder at 150°C, and obtain a modified polypropylene resin masterbatch after cooling and pelletizing; meanwhile, take 5 parts of nano-titanium dioxide, 30 parts of phenol, 20 parts of ethanol, 5 parts of triethanolamine and 5 parts of oxalic acid were mixed to obtain the immersion solution, the alkali-free glass fiber was mixed with the immersion solution in a mass ratio of 6:10, and the immersion solution was treated for 1 hour to obtain the modified long glass fiber;

[0032] Step 2: The modified polypropylene resin masterbatch obtained in step 1 is mixed with 4 parts of UF resin crosslinking agent, 2 parts of polyethylene wax, 1 part of aromatic amine, 1 part of phosphite...

Embodiment 3

[0035] Step 1: Mix and stir 20 parts of polyethylene terephthalate resin, 6 parts of superfine calcium carbonate and 8 parts of coupling agent, raise the temperature to 80°C and keep it warm, add 90 parts of low-viscosity polypropylene resin and stir for 30 minutes, Then melt and extrude at 220°C through a plastic extruder, and obtain a modified polypropylene resin masterbatch after cooling and pelletizing; meanwhile, take 10 parts of nano-titanium dioxide, 50 parts of phenol, 30 parts of ethanol, 15 parts of triethanolamine and 8 parts of oxalic acid were mixed to obtain the immersion solution, the alkali-free glass fiber was mixed with the immersion solution in a mass ratio of 4:10, and the immersion solution was treated for 2 hours to obtain a modified long glass fiber;

[0036] Step 2: The modified polypropylene resin masterbatch obtained in step 1 is mixed with 10 parts of UF resin crosslinking agent, 5 parts of polyethylene wax, 5 parts of hindered phenol, 3 parts of thio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com