Controllable post-acidification fermented milk product and preparation method thereof

A fermented dairy product, inoculated fermentation technology, applied to dairy products, bacteria used in food preparation, milk preparations, etc., can solve problems such as poor quality, easy post-acidification, sour taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

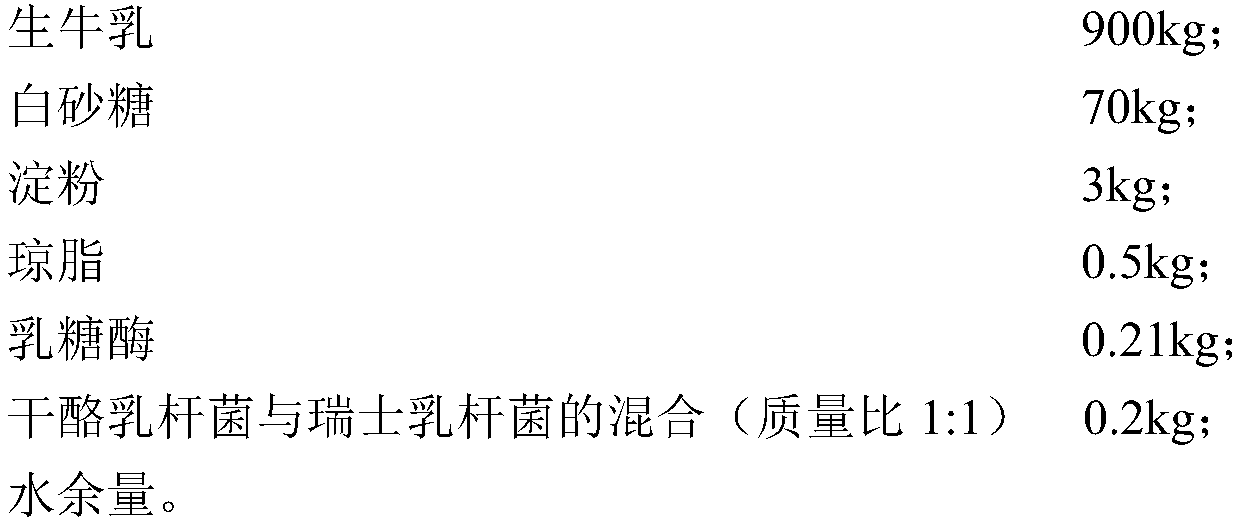

[0033] 1000kg of fermented milk products contain the following ingredients:

[0034]

[0035] Craftsmanship

[0036] 1) Ingredients: heat the raw milk to 44-45°C after standardized treatment, add white sugar, starch, agar, and water to volume;

[0037] 2) Add lactase, stir in circulation for 30-35 minutes, and the hydrolysis rate of lactose is 40%-50%;

[0038] In order to ensure the hydrolysis conditions and hydrolysis rate of lactase, it is necessary to strictly control the temperature and time. At the same time, it must be added after the ingredients are fixed to volume, instead of adding together with the starter, so as to avoid the acid production of fermentation, which will lower the pH and affect the hydrolysis;

[0039] 3) Purification and degassing: Purify and degas the material in step 1);

[0040] 4) Homogenization: Heat the purified and degassed material to 60-70°C rapidly, and perform homogenization under the pressure of 160-180bar;

[0041] 5) Sterilization...

Embodiment 2

[0048] 1000kg of fermented milk products contain the following ingredients:

[0049]

[0050] Craftsmanship

[0051] 1) Ingredients: heat the raw milk to 44-45°C after standardized treatment, add white sugar, starch, agar, and water to volume;

[0052] 2) Add lactase, stir in circulation for 30-35 minutes, and the hydrolysis rate of lactose is 40%-50%;

[0053] In order to ensure the hydrolysis conditions and hydrolysis rate of lactase, the temperature and time must be strictly controlled. At the same time, it must be added after the ingredients are fixed to volume, rather than added together with the starter, so as to avoid the acid produced by fermentation, which will lower the pH and affect the hydrolysis.

[0054] 3) Purification and degassing: Purify and degas the material in step 1);

[0055] 4) Homogenization: heat the purified and degassed material to 60-70°C, and perform homogenization under a pressure of 160-180 bar;

[0056] 5) Sterilization: Sterilization req...

Embodiment 3

[0062] 1000kg of fermented milk products contain the following ingredients:

[0063]

[0064] Craftsmanship

[0065] 1) Ingredients: heat the raw milk to 44-45°C after standardized treatment, add white sugar, starch, agar, and water to volume;

[0066] 2) Add lactase, stir in circulation for 30-35 minutes, and the hydrolysis rate of lactose is 40%-50%;

[0067] In order to ensure the hydrolysis conditions and hydrolysis rate of lactase, the temperature and time must be strictly controlled. At the same time, it must be added after the ingredients are fixed to volume, rather than added together with the starter, so as to avoid the acid produced by fermentation, which will lower the pH and affect the hydrolysis.

[0068] 3) Purification and degassing: Purify and degas the material in step 1);

[0069] 4) Homogenization: heat the purified and degassed material to 60-70°C, and perform homogenization under a pressure of 160-180 bar;

[0070] 5) Sterilization: Sterilization req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com