Horizontal type automatic wrapping machine

A horizontal winding machine, automatic technology, applied in the direction of packaging, conveyor belt wrapping, etc., can solve the problems of uneven control of film discharge force, poor film discharge effect with constant force, complex mechanism structure, etc., to achieve good film discharge effect, The effect of ideal processing effect and simple mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be clearly and completely described below. It should be noted that, in order to illustrate the structural positional relationship of the present invention, the orientation terms such as "upper", "lower", "end", "vertical" and "horizontal" in the present invention are all aimed at figure 1 In terms of the position of use, it should not be construed as a limitation of the present invention.

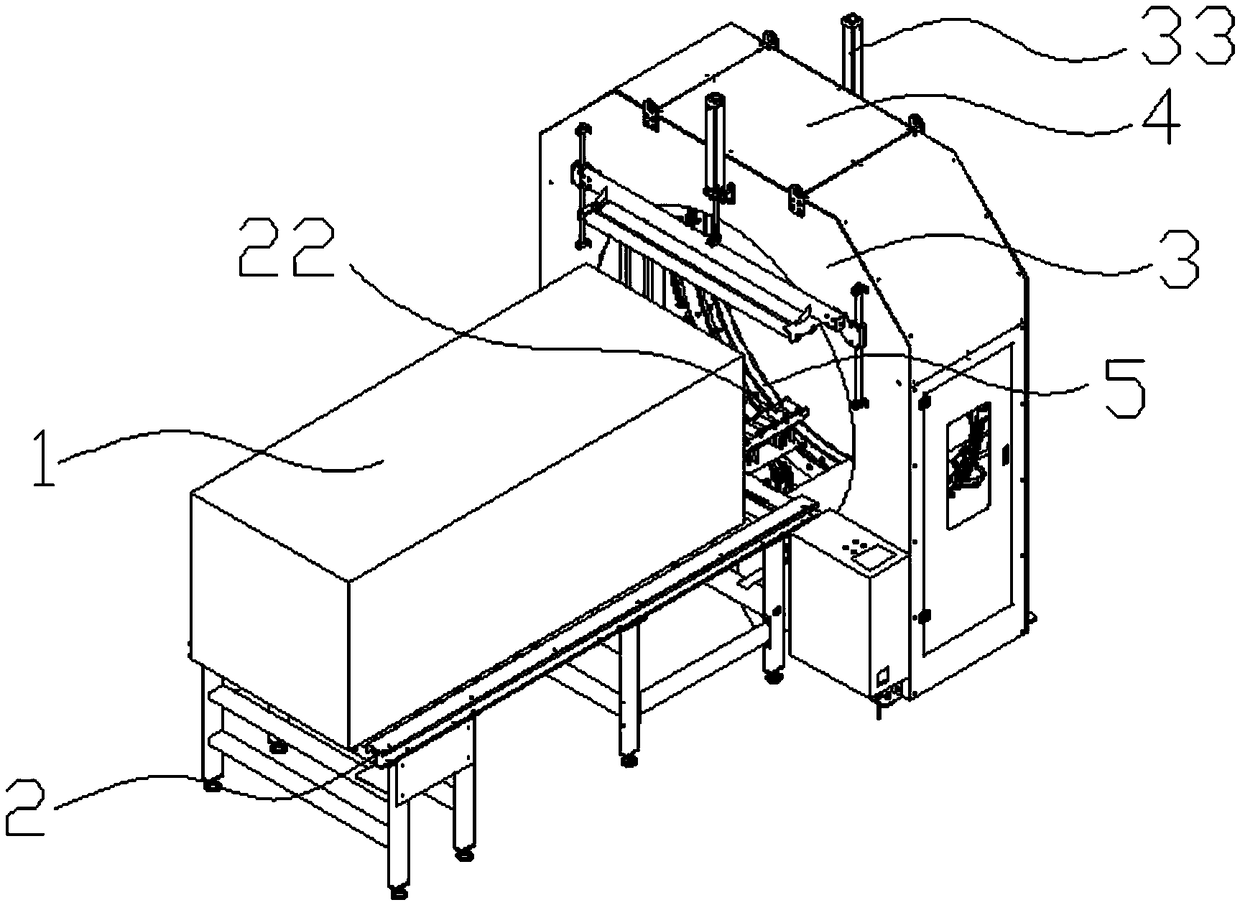

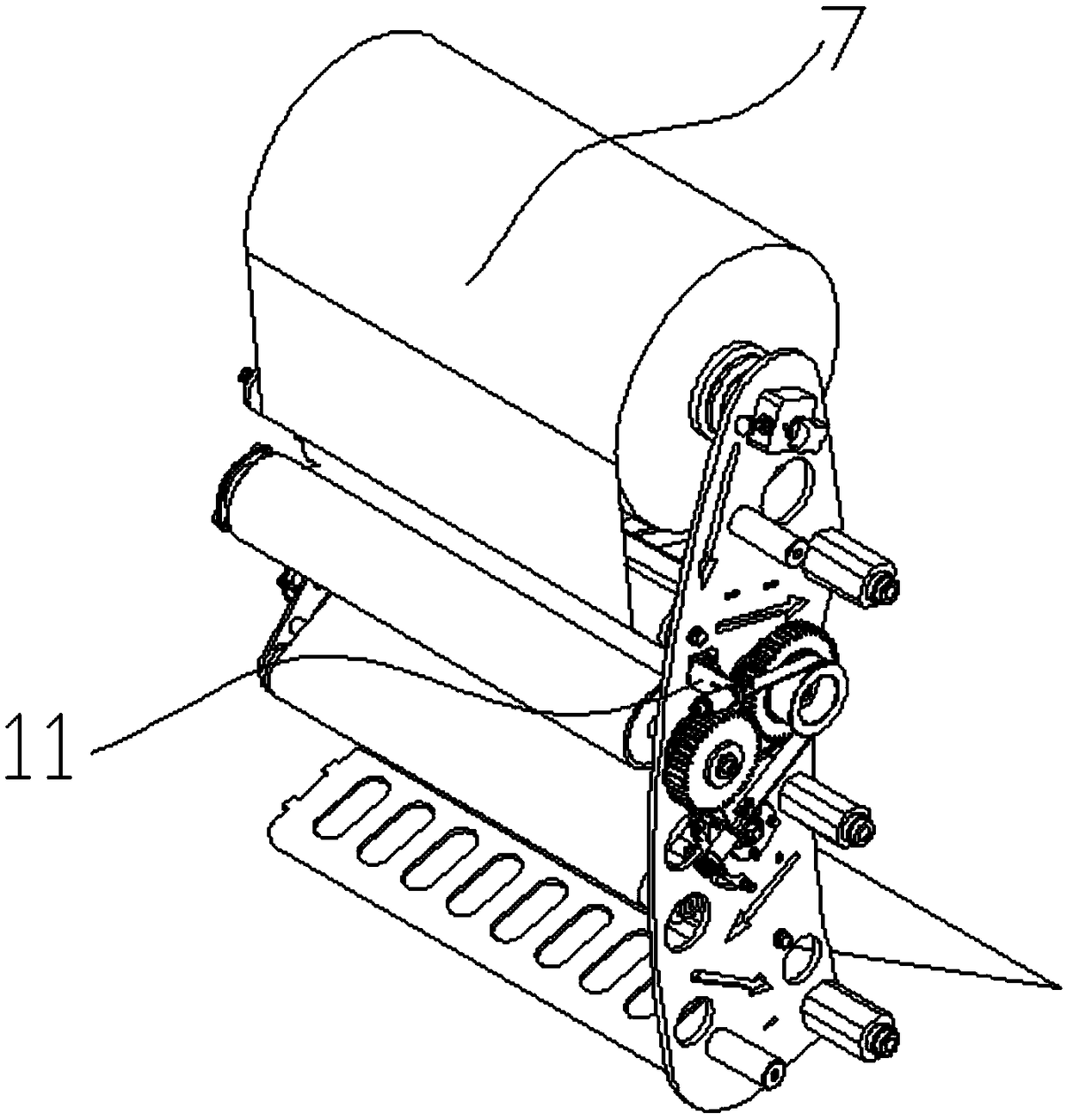

[0037] Such as figure 1 As shown, an automatic horizontal winding machine includes: a conveying device 2, a film seat device, a rotating host, a film cutting device, and a tail film processing device;

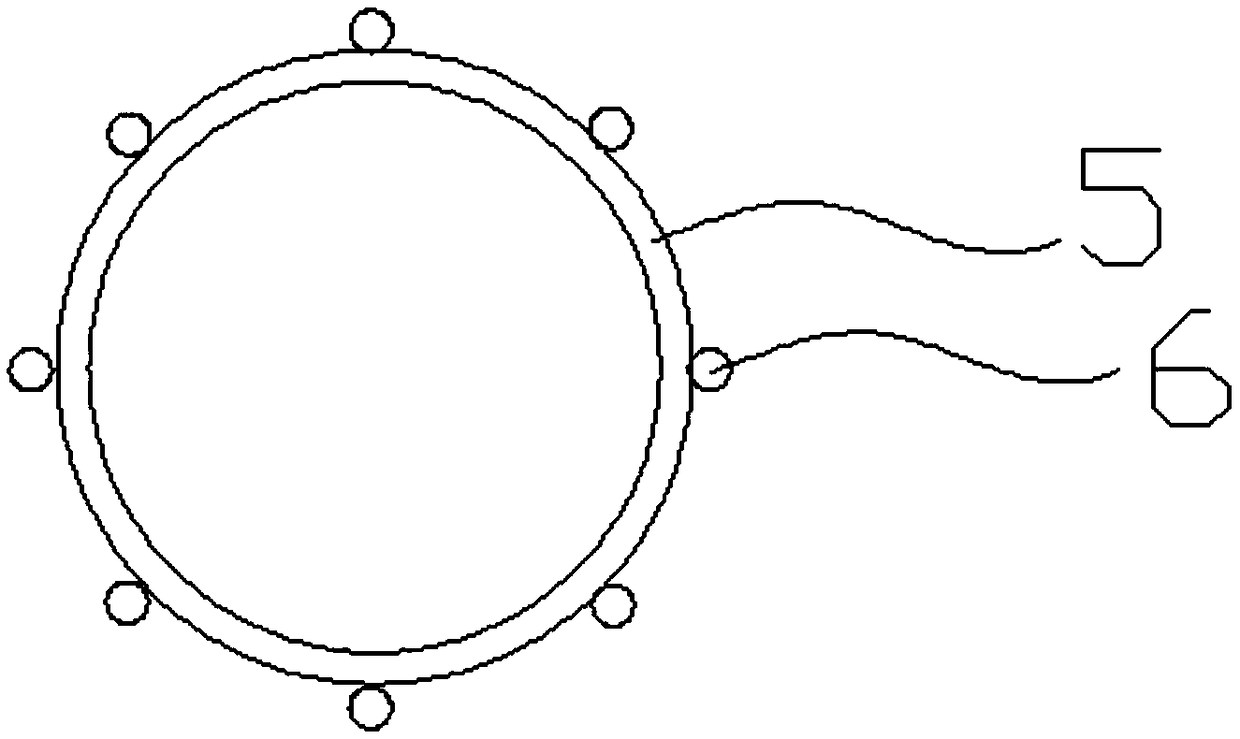

[0038] The rotating host includes a swivel 5 and a fixed frame, and the swivel rotates and is placed in the fixed frame. The fixed frame includes a wallboard 3 and a peripheral board 4, and the wallboard and the peripheral board are connected by a bolt-locked splicing type; and the front and rear The wallboard adopts standard prof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com