Film laminate metal plate having exceptional retort adhesion, and method for manufacturing same

A manufacturing method and technology of metal plates, applied in lamination, lamination devices, metal layered products, etc., can solve problems such as easy pinholes, difficulty in decompression, and entrapment of air bubbles, so as to expand the application range, film Effect of small peeling length and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] The film-laminated metal plate for food containers of the present invention will be specifically described by giving examples. However, the conditions in the examples are examples of conditions adopted for confirming the practicability and effects of the present invention, and the present invention is not limited to the following examples. As long as the object of the present invention is achieved without departing from the gist of the present invention, it can be appropriately modified and implemented within the range that can fit the gist. Therefore, the present invention can adopt various conditions, which are included in the technical characteristics of the present invention.

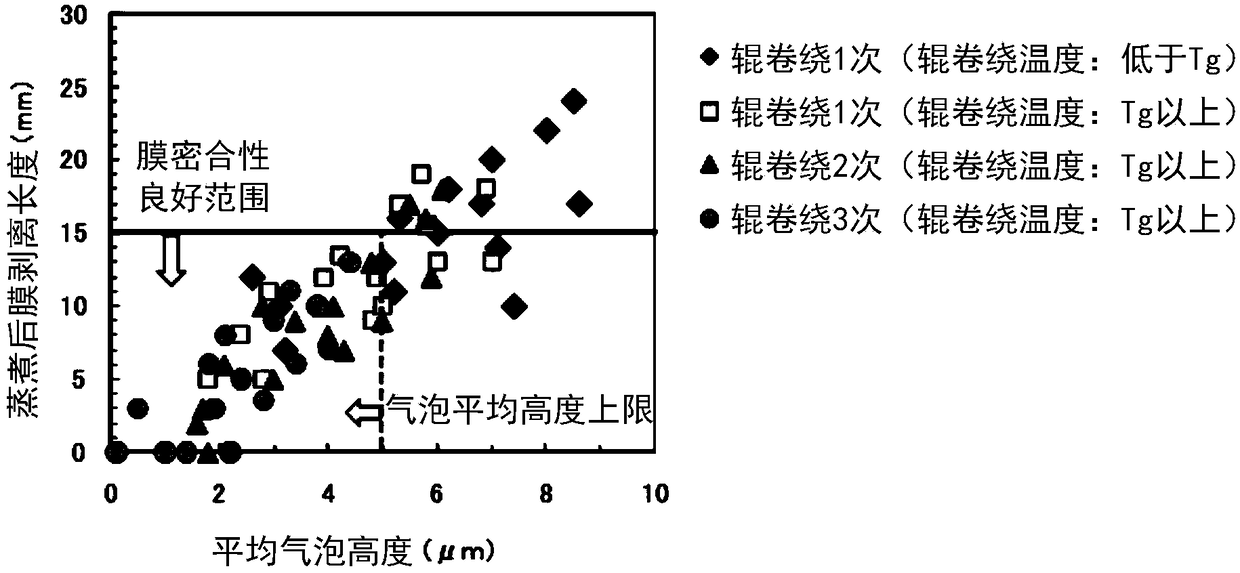

[0106] Through Examples and Comparative Examples, for the metal plates shown in Table 1, the films obtained by laminating the resin films shown in Table 2 on the metal plates under the conditions shown in Table 3 were laminated to metal plates In the unsintered state and after the sintering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com