Alkali-free boroalumino silicate glasses

A glass and oxide technology, used in glass forming, glass forming, glass manufacturing equipment, etc., can solve problems such as metal defects, inability to properly melt batch materials, affecting loading and retrieval capabilities, and reduce elastic sag. , reduce the risk of devitrification, the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

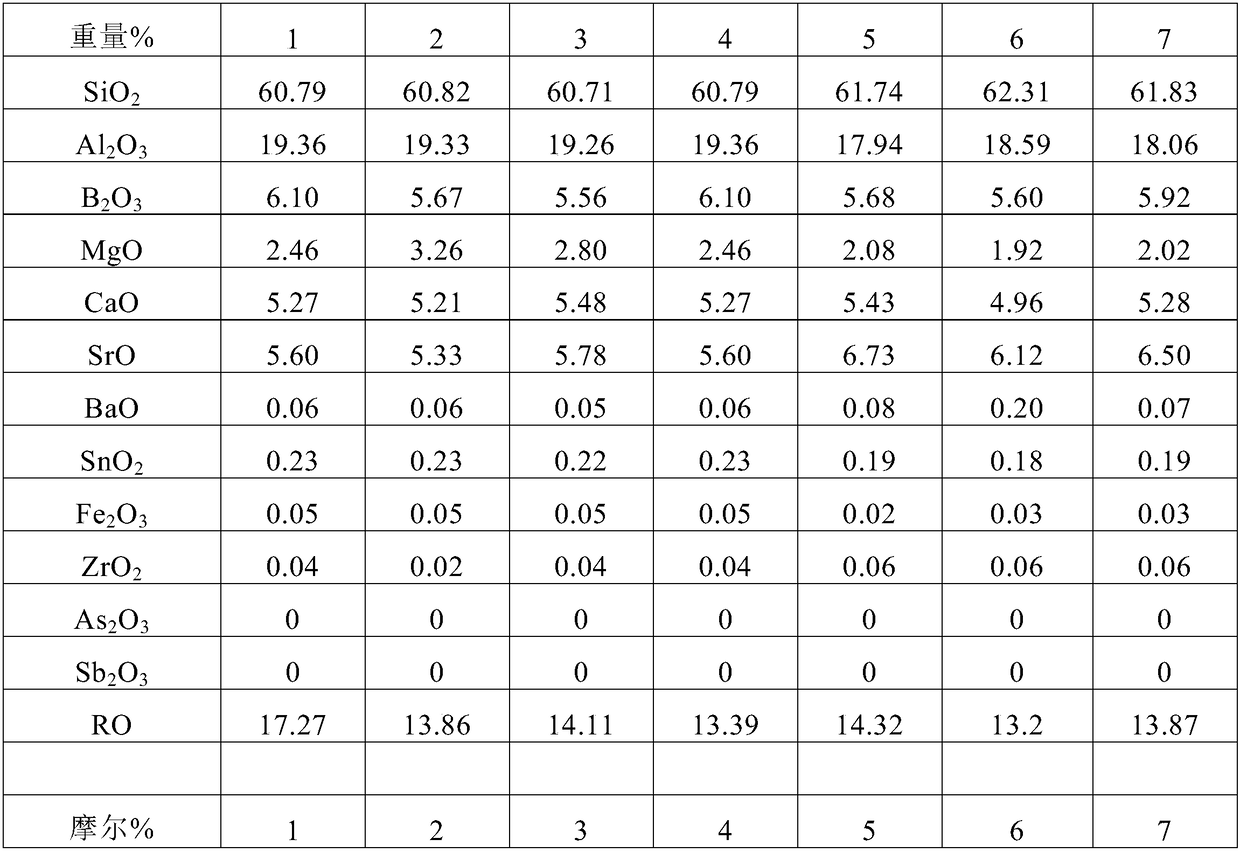

[0083] The following examples are intended to illustrate exemplary embodiments. These examples are not intended to be inclusive of all embodiments of the subject matter disclosed herein, but are intended to illustrate representative methods and results. These examples are not intended to exclude equivalents and variations of the invention which are obvious to those skilled in the art.

[0084] Efforts have been made to ensure accuracy with respect to numbers (eg, amounts, temperature, etc.), but some errors and deviations must be accounted for. Unless indicated otherwise, temperature is in °C or is at ambient temperature, and pressure is at or near atmospheric. The compositions themselves are given in mole % based on oxide and have been normalized to 100%. There are numerous variations and combinations of reaction conditions such as component concentrations, temperature, pressure and other reaction ranges and conditions that can be used to optimize product purity and yield o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| annealing point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com