Method and device for energy conservation and emission reduction of exhaust gas/pollutants of coke making enterprise

A technology for energy saving, emission reduction, and pollutants, which is applied in chemical instruments and methods, chemical industry, separation methods, etc., can solve problems such as backward production technology, pollution, air pollution, etc., achieve high efficiency and low cost, reduce emissions, reduce The effect of the cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

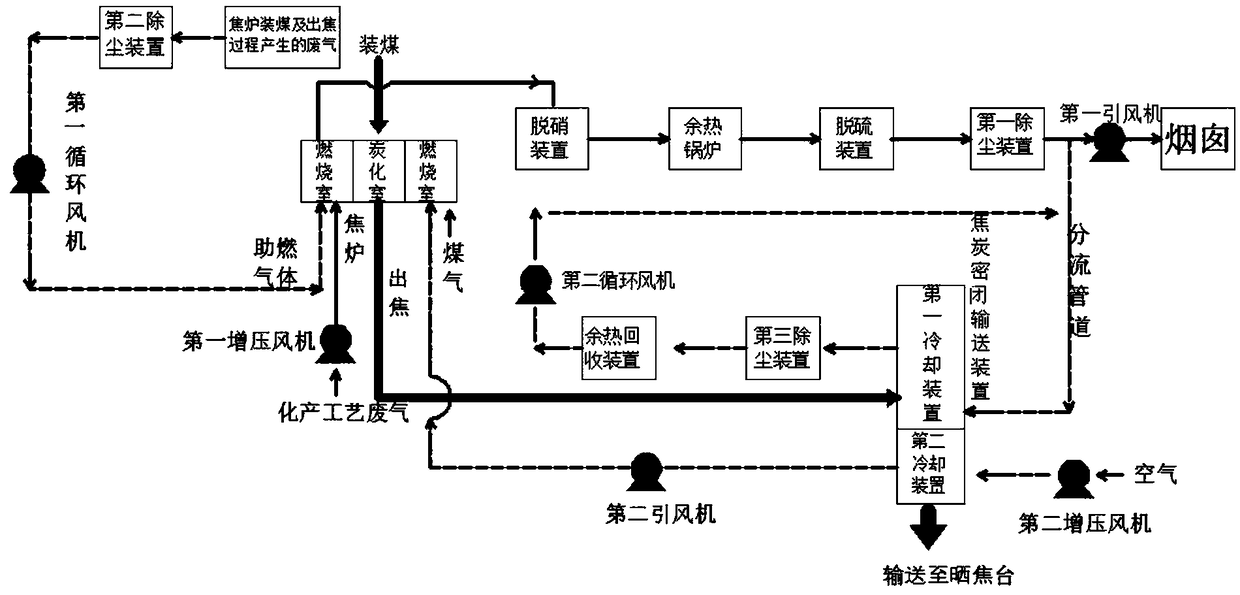

[0054] A coking enterprise waste gas / pollutant energy saving and emission reduction method, comprising:

[0055] The exhaust gas generated during the coke oven charging and coke discharge process enters the second dust removal device, and the first circulation fan enters the coke oven combustion chamber through the combustion-supporting gas inlet;

[0056] The high-temperature coke produced in the carbonization chamber of the coke oven is subjected to primary cooling and secondary cooling respectively through the first cooling device and the second cooling device in the coke airtight conveying device through the coke outlet to obtain primary cooling coke and secondary cooling coke. The final coke is transported to the coke drying platform; the temperature of the first-stage cooling coke is 200°C, and the temperature of the second-stage cooling coke is 50°C;

[0057] The gas of the first cooling device is the flue gas generated by the combustion chamber, which passes through th...

Embodiment 2

[0062] A coking enterprise waste gas / pollutant energy saving and emission reduction method, comprising:

[0063] The exhaust gas generated during the coke oven charging and coke discharge process enters the second dust removal device, and the first circulation fan enters the coke oven combustion chamber through the combustion-supporting gas inlet;

[0064] The high-temperature coke produced in the carbonization chamber of the coke oven is subjected to primary cooling and secondary cooling respectively through the first cooling device and the second cooling device contained in the coke airtight conveying device through the coke outlet to obtain primary cooling coke and secondary cooling coke; cooling The final coke is transported to the coke drying platform; the temperature of the first-stage cooling coke is 220°C, and the temperature of the second-stage cooling coke is 80°C;

[0065] The gas of the first cooling device is the flue gas generated by the combustion chamber, which...

Embodiment 3

[0070] A coking enterprise waste gas / pollutant energy saving and emission reduction method, comprising:

[0071] The exhaust gas generated during the coke oven charging and coke discharge process enters the second dust removal device, and the first circulation fan enters the coke oven combustion chamber through the combustion-supporting gas inlet;

[0072] The high-temperature coke produced in the carbonization chamber of the coke oven passes through the coke outlet through the first cooling device and the second cooling device contained in the coke airtight conveying device to perform primary cooling and secondary cooling respectively, to obtain primary cooling coke and secondary cooling coke, cooling The final coke is transported to the coke drying platform; the temperature of the first-stage cooling coke is 190°C, and the temperature of the second-stage cooling coke is 50°C;

[0073] The gas of the first cooling device is the flue gas generated by the combustion chamber, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com