Preparation and application of nitrogen vacancy-modified oxygen-rich titanium dioxide nano composite material

A titanium dioxide, composite material technology, applied in the directions of carbon monoxide, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

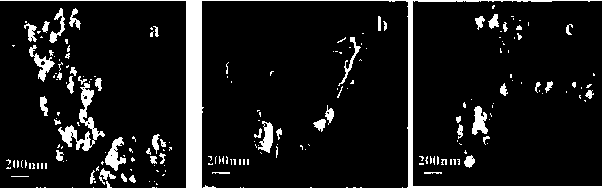

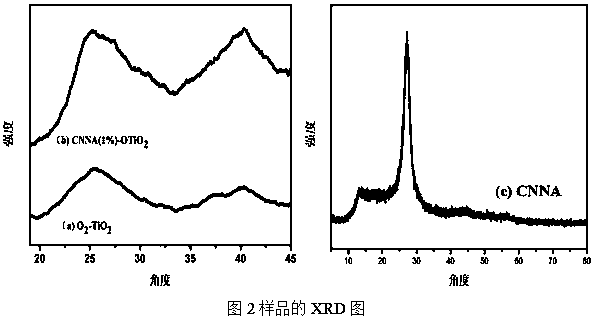

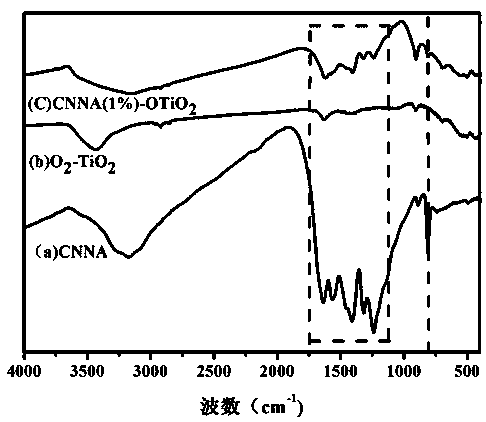

Image

Examples

Embodiment 1

[0031] (1) Preparation of CNNA: Add 7.5g of melamine to 50ml of deionized water under magnetic stirring, and keep the system stirring at 50°C for 1h; add 2ml of nitric acid until a white solid precipitates, and heat to 100°C to evaporate water; finally, the white The solid material was put into a muffle furnace, heated to 550°C at a rate of 5°C / min, and calcined for 3 hours to obtain CNNA (g-C 3 N 4 );

[0032] (2) Synthesis of peroxotitanate complex: slowly add 3mL TBOT into 50mL cold water (5°C), immediately produce white precipitate; after repeated washing with deionized water, add the precipitate under magnetic stirring to 50ml deionized water and 25ml H 2 o 2 In the mixed solution, keep the temperature at 5°C and stir for 1 hour to obtain the orange peroxotitanate complex O 2 -TiO 2 ;

[0033] (3) CNNA(1%)-OTiO 2 Preparation of: Add 0.07 g of CNNA to the above orange peroxotitanate complex O 2 -TiO 2 , heated to 50°C for 4 hours; the reaction solution was dried o...

Embodiment 2

[0036] (1) Preparation of CNNA: Same as Example 1;

[0037] (2) Preparation of peroxotitanate complex: slowly add 3mL TBOT into 50mL cold water (5°C), and immediately produce a white precipitate; after repeated washing of the precipitate with deionized water, add the precipitate under magnetic stirring to 50ml deionized water and 50ml H 2 o 2 In the mixed solution, keep the temperature at 5°C and stir for 1 hour to obtain the orange peroxotitanate complex O 2 -TiO 2 ;

[0038] (3) CNNA(5%)-OTiO 2 Synthesis of: take 0.35g CNNA, add orange peroxotitanate complex O 2 -TiO 2 , heated to 50°C for 4 hours; the reaction solution was dried overnight in an air oven at 100°C to obtain a yellow solid substance CNNA(5%)-OTiO 2 ;

[0039] (4) Photocatalytic reduction performance: CNNA(5%)-OTiO 2 As a catalyst, under the irradiation of 300W xenon lamp, the amount of carbon monoxide produced can reach 12μmol / g.

Embodiment 3

[0041] (1) Preparation of CNNA: Same as Example 1;

[0042] (2) Preparation of peroxotitanate complex: Take 3 mL of TBOT and slowly add it to 50 mL of cold water (5°C), and immediately produce a white precipitate; after repeated washing of the precipitate with deionized water, dissolve the precipitate under magnetic stirring Add to 50ml deionized water and 35mlH 2 o 2 In the mixed solution, keep the temperature at 5°C and stir for 1 hour to obtain the orange peroxotitanate complex O 2 -TiO 2 ;

[0043] (3) CNNA(10%)-OTiO 2 Synthesis of: take 0.7g CNNA, add orange peroxotitanate complex O 2 -TiO 2 , heated to 50°C for 4 hours; the reaction solution was dried overnight in an air oven at 100°C to obtain a yellow solid substance CNNA(10%)-OTiO 2 ;

[0044] (4) Photocatalytic reduction performance: CNNA(10%)-OTiO 2 As a catalyst, under the irradiation of 300W xenon lamp, the amount of carbon monoxide produced can reach 11μmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com