Casing method of alloy cast iron cylinder jacket

A technology of alloy cast iron and cylinder liner, which is applied in the field of cylinder liner casting and alloy cast iron cylinder liner casting to achieve the effect of compact structure, ensuring dimensional accuracy and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

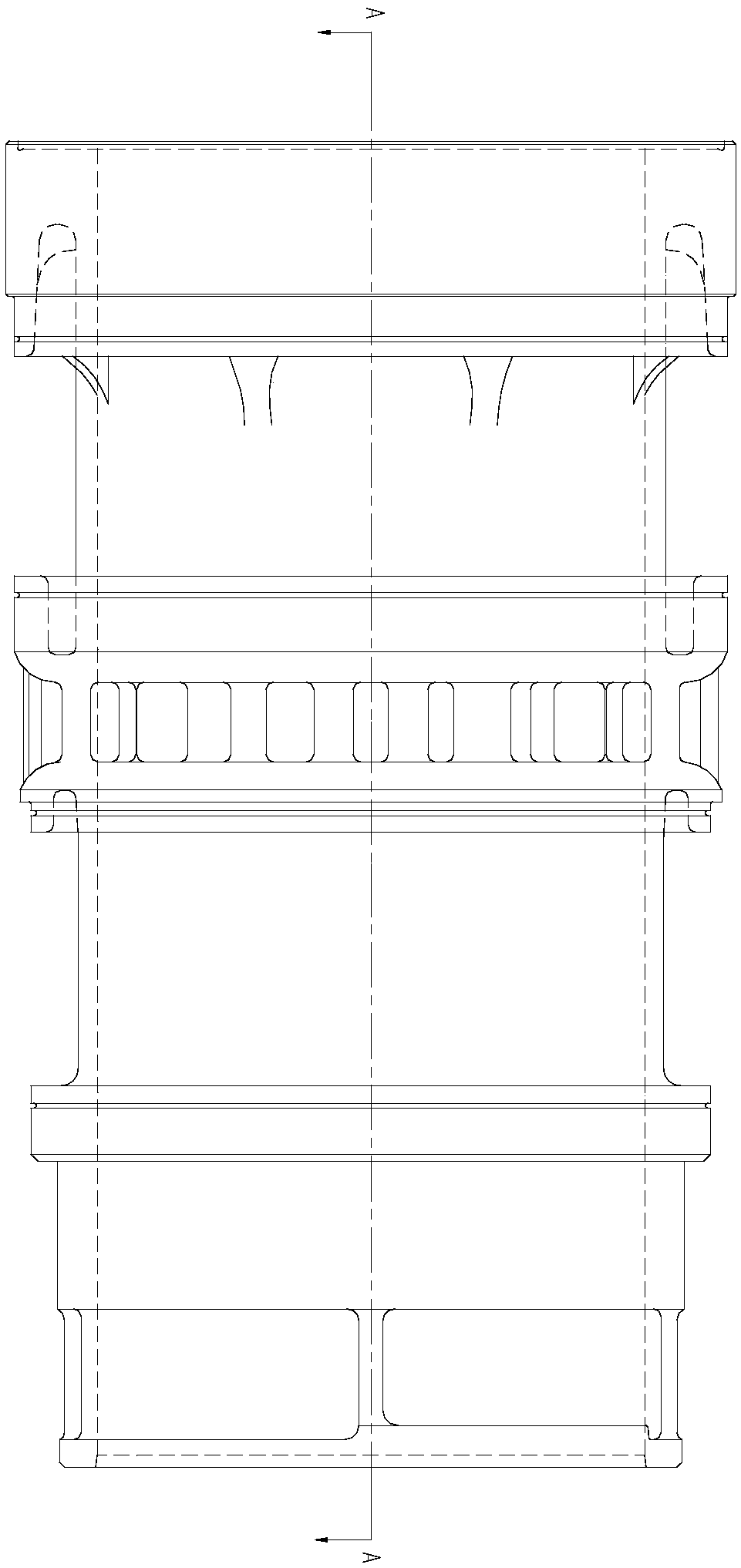

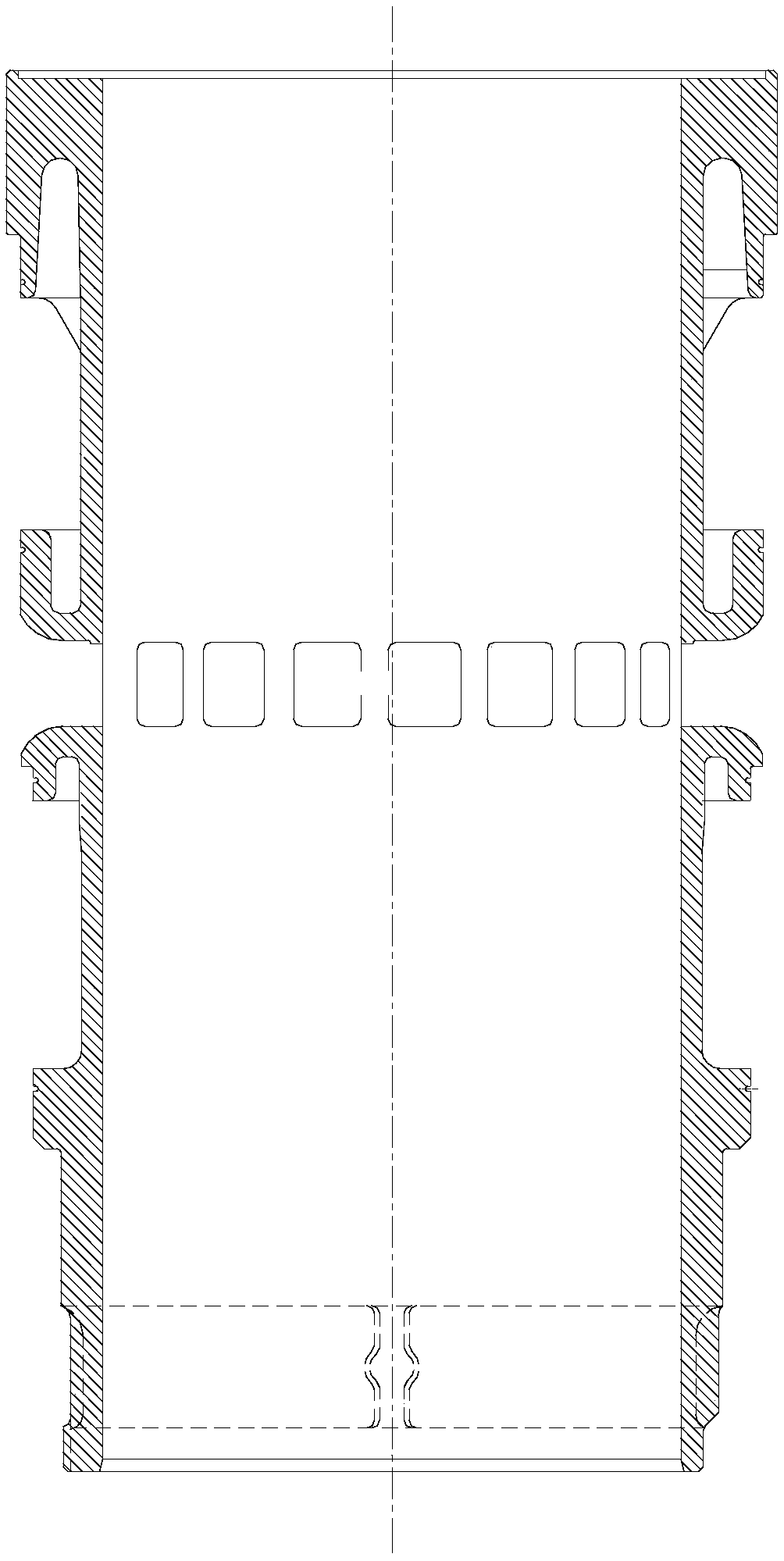

Image

Examples

Embodiment 1

[0051] The present embodiment provides a method for casting an alloy cast iron cylinder liner, comprising the following steps:

[0052] (1) Molding and core making: use furan resin sand to make the outer mold of the upper, middle and lower box structure structure respectively through the upper box tire mold, middle box tire mold and lower box tire mold; use furan resin sand to pass through the upper main body core mold 1. The main body core mold in the middle section and the main body core mold in the lower section are divided into three sections to make the main body core;

[0053] (2) Manufacture of film-coated sand cores: Use coated sand to make side riser cores, bottom cores, petal cores, water hole cores, upper petal cores and top cores, and then superimpose and fix the bottom cores, petal cores, The water hole core, the upper petal core and the top core, the side riser is preset on the side of the bottom core, the water hole core and the petal core, and the side riser co...

Embodiment 2

[0066] The embodiment provides a casting method of an alloy cast iron cylinder liner, the casting mold is consistent with the structure of embodiment 1, the main difference is the difference in the casting process, and the casting method mainly includes the following steps:

[0067] (1) Molding and core making: use furan resin sand to make the outer mold of the upper, middle and lower box structure structure respectively through the upper box tire mold, middle box tire mold and lower box tire mold; use furan resin sand to pass through the upper main body core mold 1. The main body core mold in the middle section and the main body core mold in the lower section are divided into three sections to make the main body core;

[0068] (2) Manufacture of film-coated sand cores: Use coated sand to make side riser cores, bottom cores, petal cores, water hole cores, upper petal cores and top cores, and then superimpose and fix the bottom cores, petal cores, The water hole core, the upper...

Embodiment 3

[0074] The embodiment provides a casting method of an alloy cast iron cylinder liner, the casting mold is consistent with the structure of embodiment 1, the main difference is the difference in the casting process, and the casting method mainly includes the following steps:

[0075] (1) Molding and core making: use furan resin sand to make the outer mold of the upper, middle and lower box structure structure respectively through the upper box tire mold, middle box tire mold and lower box tire mold; use furan resin sand to pass through the upper main body core mold 1. The main body core mold in the middle section and the main body core mold in the lower section are divided into three sections to make the main body core;

[0076] (2) Manufacture of film-coated sand cores: Use coated sand to make side riser cores, bottom cores, petal cores, water hole cores, upper petal cores and top cores, and then superimpose and fix the bottom cores, petal cores, The water hole core, the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com