Method for preparing starch films for inhibiting post-harvest fungi

A technology of starch film and fungus, which is applied in the fields of agriculture, biology and food. It can solve the problems of affecting transparency and darkening the color, and achieve the effect of easy film formation and bubble removal, low viscosity and good emulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

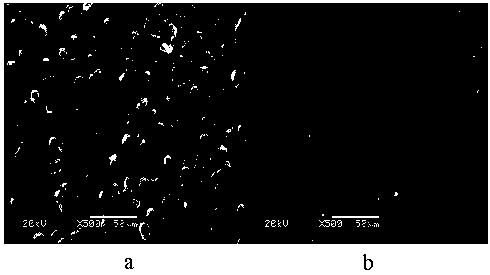

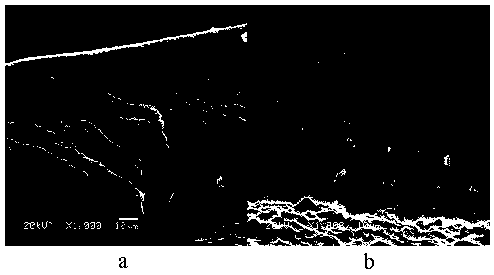

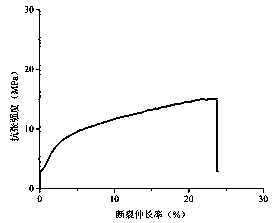

Image

Examples

Embodiment 1

[0037] Embodiment 1 A kind of starch film preparation method that suppresses postharvest fungus, comprises the following steps:

[0038] (1) Add distilled water 30 times the mass of microporous octenyl succinate cornstarch, and completely gelatinize it at 90°C to obtain gelatinized starch.

[0039] (2) Add 1% acetic acid solution with a volume concentration of 50 times its mass to chitosan, and dissolve it at 30°C to obtain a transparent solution.

[0040] Wherein: the amount of chitosan accounts for 51% of the quality of microporous octenyl succinate cornstarch.

[0041] (3) Cool the gelatinized starch and the transparent solution to room temperature and mix them uniformly to obtain a mixture. Add glycerin and cumin essential oil to the mixture, undergo homogeneous emulsification at a pressure of 20 MPa for 30 minutes, and debubble at a power of 120 W for 30 minutes to obtain a film liquid.

[0042] Wherein: the amount of glycerin added is 10% of the mass of the microporous ...

Embodiment 2

[0045] Embodiment 2 A kind of starch film preparation method that suppresses postharvest fungus, comprises the following steps:

[0046] (1) Add distilled water 100 times the mass of microporous octenyl succinate cornstarch, and completely gelatinize it at 90°C to obtain gelatinized starch.

[0047] ⑵Add 100 times its mass of acetic acid solution with a volume concentration of 2% to chitosan, dissolve it at 80°C to obtain a transparent solution.

[0048] Wherein: the consumption of chitosan accounts for 70% of the quality of microporous octenyl succinate cornstarch.

[0049] (3) Cool the gelatinized starch and the transparent solution to room temperature and mix them uniformly to obtain a mixture. Add glycerin and cumin essential oil to the mixture, undergo homogeneous emulsification at a pressure of 100 MPa for 60 minutes, and debubble at a power of 600W for 30 minutes to obtain a film liquid.

[0050] Wherein: the amount of glycerin added is 19% of the mass of the microporo...

Embodiment 3

[0053] Embodiment 3 A kind of starch film preparation method that suppresses postharvest fungus, comprises the following steps:

[0054] (1) Add distilled water 70 times its mass to octenyl succinate cornstarch, and completely gelatinize it at 90°C to obtain gelatinized starch.

[0055] (2) Add 10% acetic acid solution with a volume concentration of 88 times its mass to chitosan, and dissolve it at 60°C to obtain a transparent solution.

[0056] Wherein: the consumption of chitosan accounts for 30% of octenyl succinate cornstarch quality.

[0057] (3) Cool the gelatinized starch and the transparent solution to room temperature and mix them uniformly to obtain a mixture. Add glycerin and essential oils to the mixture, undergo homogeneous emulsification at a pressure of 80 MPa for 40 minutes, and debubble at a power of 200 W for 20 minutes to obtain a film liquid.

[0058] Wherein: the addition amount of glycerin is 20% of the mass of octenyl succinate corn starch; the addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com