Device for using high-temperature converter gas and increasing heat value and use method of device

A converter gas, high temperature technology, applied in the field of steelmaking converter gas utilization, can solve the problems of safety hazards, low CO concentration, high-temperature converter gas chemical reaction heat application effect is not very good, etc., to achieve the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

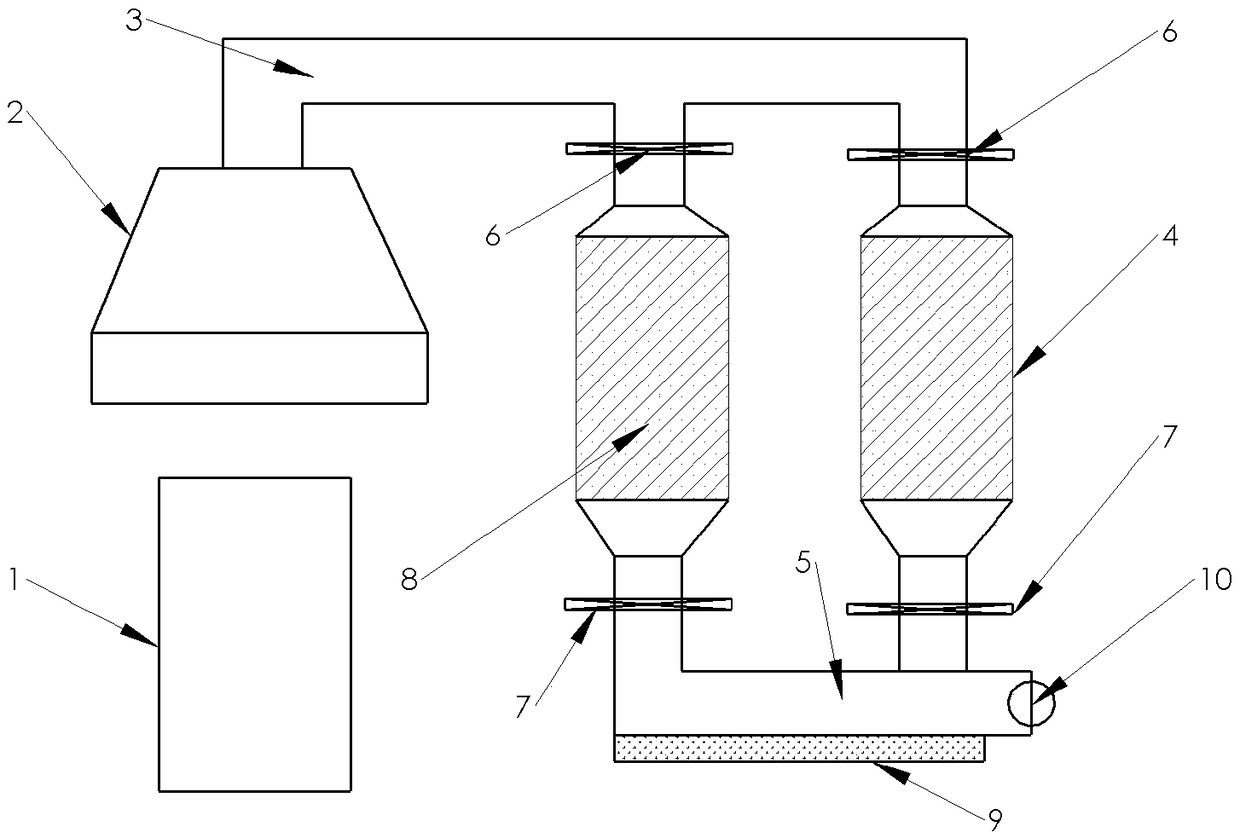

Method used

Image

Examples

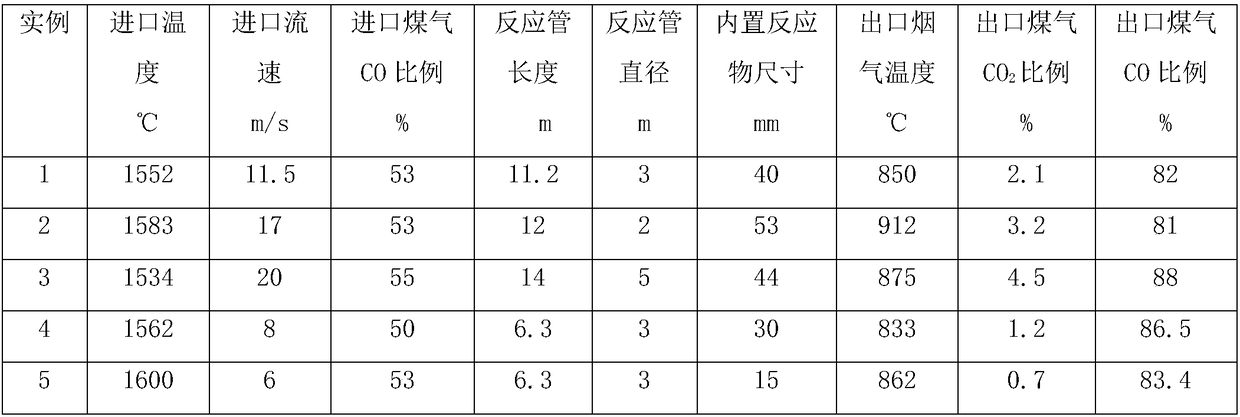

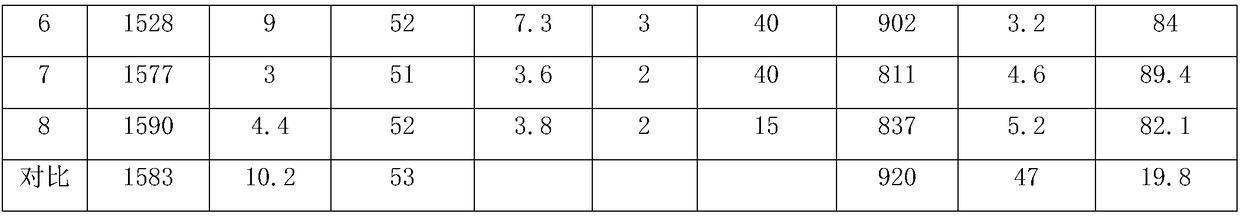

Embodiment 1

[0025] The converter gas generated from the converter reaches the carbon loss reactor 4 through the movable hood 2 and the fixed flue 3. The initial converter gas flow rate is 11.5m / s, the flue gas temperature measured by infrared temperature is 1552°C, and the CO concentration in the converter flue gas 53%, then carbon loss reaction occurs in the carbon loss reactor 4, the length of the carbon loss reactor 4 is 11.2m, the degree of 8 built-in cokes is 40mm, the diameter of the carbon loss reactor 4 is 3m, and the temperature is reduced to 850°C. Then it is discharged through the water-cooled elbow 5 and subjected to subsequent dust removal treatment. The flue gas at the outlet was analyzed, the CO concentration in the outlet flue gas rose to 82%, and the CO 2 The concentration dropped to 2.1%.

Embodiment 2

[0027] The converter gas generated from the converter reaches the carbon loss reactor 4 through the movable hood 2 and the fixed flue 3. The initial converter gas flow rate is 17m / s, the flue gas temperature measured by infrared temperature is 1583°C, and the CO in the converter flue gas 2 Concentration is 53%, and carbon loss reaction takes place in carbon loss reactor 4 then, and this carbon loss reactor 4 is long 12m, and built-in coke, machine-pressed charcoal average size are 53mm, and carbon loss reactor 4 diameter is 2m, and temperature drops to 912°C, and then discharged through the water-cooled elbow 5 for subsequent dust removal treatment. The flue gas at the outlet was analyzed, and the concentration of CO in the flue gas at the outlet rose to 81%. 2 The concentration dropped to 3.2%.

Embodiment 3

[0029] The converter gas generated from the converter reaches the carbon loss reactor 4 through the movable hood 2 and the fixed flue 3. The initial converter gas flow rate is 20 m / s, the flue gas temperature measured by infrared temperature is 1534 °C, and the CO concentration in the converter flue gas is 55%, and then a carbon loss reaction occurs in the carbon loss reactor 4, the carbon loss reactor is 14m long, the average size of the built-in semi-coke is 44mm, the diameter of the carbon loss reactor 4 is 5m, the temperature is reduced to 875 ° C, and then The water-cooled elbow 5 is discharged and subjected to subsequent dust removal treatment. The flue gas at the outlet was analyzed, the CO concentration in the outlet flue gas rose to 88%, and the CO 2 The concentration drops to 4.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com