Production method of high-performance hiking camping tent fabric

A tent fabric and production method technology, applied in the processing of textile materials, liquid/gas/vapor textile material processing, textile and other directions, can solve the problems of low fiber density, etc., achieve high specific energy absorption, long flex life, prevent Effects of lacerations and cuts in the wild

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

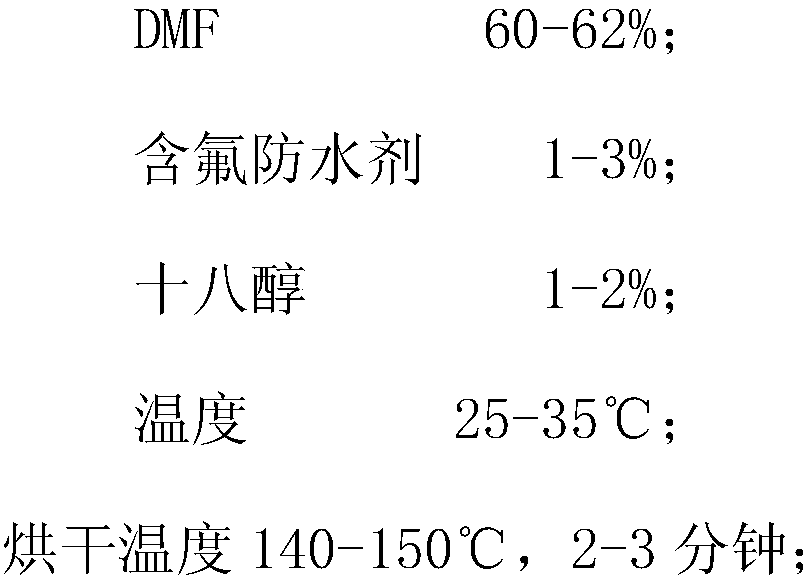

Examples

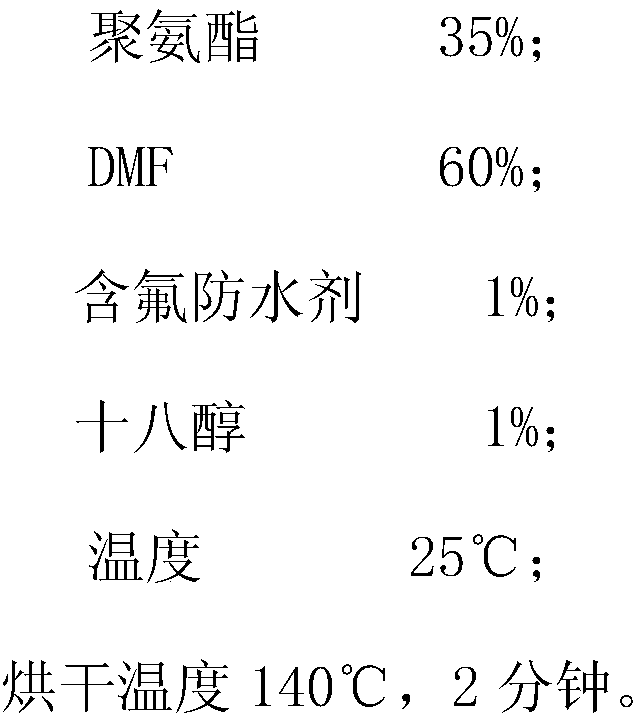

specific Embodiment 1

[0034] A production method of a high-performance trekking and camping tent fabric, comprising the following steps: Winding—warping—sizing—doubling—splitting—threading and reeding—machine weaving—fabric treatment— Drying process - PU coating - packaging.

[0035] The above-mentioned warping: this process adopts sub-shaft warping, which is to divide a whole shaft into several to be adjusted, and then merge into one whole shaft after passing through the sizing; the warping speed is set at 900m / min, warp beam winding density is 0.48g / cm 3 .

[0036] The sizing described above: pull the finished warp beam to the sizing machine, let the warp surface absorb the slurry through the sizing tank, dry it through the oven, and then roll it onto the empty disc; the purpose of the sizing is to make the single The fibers are bonded to each other to increase the breaking strength of the filaments to facilitate smooth weaving on the machine.

specific Embodiment 2

[0048] A production method of a high-performance trekking and camping tent fabric, comprising the following steps: Winding—warping—sizing—doubling—splitting—threading and reeding—machine weaving—fabric treatment— Drying process - PU coating - packaging.

[0049] The warping described above: this process adopts the warping of sub-shafts, and the warping of sub-shafts is to divide a whole shaft into several to be adjusted, and then merge into one whole shaft after passing through the sizing; the warping speed is set at 1000m / min, warp beam winding density is 0.53g / cm 3 .

[0050] The sizing described above: pull the finished warp beam to the sizing machine, let the warp surface absorb the slurry through the sizing tank, dry it through the oven, and then roll it onto the empty disc; the purpose of the sizing is to make the single The fibers are bonded to each other to increase the breaking strength of the filaments to facilitate smooth weaving on the machine.

[0051] Sizing ...

specific Embodiment 3

[0062] A production method of a high-performance trekking and camping tent fabric, comprising the following steps: Winding—warping—sizing—doubling—splitting—threading and reeding—machine weaving—fabric treatment— Drying process - PU coating - packaging;

[0063] The warping described above: this process adopts the warping of sub-shafts, and the warping of sub-shafts is to divide a whole shaft into several to be adjusted, and then merge into one whole shaft after passing through the sizing; the warping speed is set at 950m / min, warp beam winding density is 0.51g / cm 3 ;

[0064] The sizing described above: pull the finished warp beam to the sizing machine, let the warp surface absorb the slurry through the sizing tank, dry it through the oven, and then roll it onto the empty disc; the purpose of the sizing is to make the single The fibers are bonded to each other to increase the breaking strength of the filaments, so as to facilitate the smooth weaving of the upper machine; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com