Compound modified starch printing paste for polyester and preparation method of compound modified starch printing paste

A technology of modified starch and printing paste, applied in the field of textile dyeing and finishing, which can solve the problems of long process flow, serious color sticking, large dosage, etc., and achieve the effects of reasonable compatibility, good hand feeling and water holding capacity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

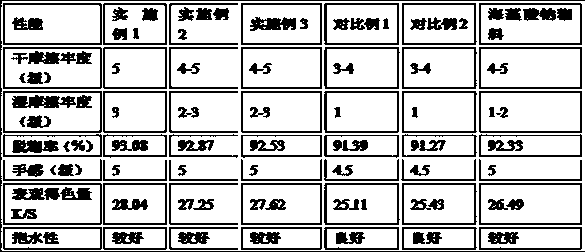

Examples

Embodiment 1

[0015] Example 1 A kind of compound modified starch printing paste for polyester

[0016] A compound modified starch printing paste for polyester, which is mainly prepared from the following raw materials in parts by mass: 45 parts of modified starch, 15 parts of hydroxyethyl tamarind gum, 12 parts of konjac gum, 10 parts of anhydrous sodium sulfate, 8 parts of sodium hexametaphosphate and 2 parts of sodium butyl p-hydroxybenzoate; the modified starch is prepared from phosphate starch and acetate starch in a ratio of 5:2.

[0017] The preparation method of the compound modified starch printing paste for the polyester comprises the following steps:

[0018] (1) Preparation of phosphate starch: Weigh starch, potassium dihydrogen phosphate, phosphoric acid and urea respectively according to the weight ratio of starch: potassium dihydrogen phosphate: phosphoric acid: urea = 75:6:3:4, and accurately weigh the The starch is placed in a vacuum esterification reaction tank, and the a...

Embodiment 2

[0021] Example 2 A kind of compound modified starch printing paste for polyester

[0022] A compound modified starch printing paste for polyester, which is mainly prepared from the following raw materials in parts by mass: 30 parts of modified starch, 10 parts of hydroxyethyl tamarind gum, 10 parts of konjac gum, 5 parts of anhydrous sodium sulfate, 5 parts of sodium hexametaphosphate and 1 part of sodium butyl p-hydroxybenzoate; the modified starch is configured from phosphate starch and acetate starch in a ratio of 5:3.

[0023] The preparation method of the compound modified starch printing paste for the polyester comprises the following steps:

[0024] (1) Preparation of phosphate starch: Weigh starch, potassium dihydrogen phosphate, phosphoric acid and urea respectively according to the weight ratio of starch: potassium dihydrogen phosphate: phosphoric acid: urea = 60:4:1:3, and accurately weigh the The starch is placed in a vacuum esterification reaction tank, and the a...

Embodiment 3

[0027] Example 3 A kind of compound modified starch printing paste for polyester

[0028] A compound modified starch printing paste for polyester, which is mainly prepared from the following raw materials in parts by mass: 50 parts of modified starch, 20 parts of hydroxyethyl tamarind gum, 20 parts of konjac gum, 15 parts of anhydrous sodium sulfate, 15 parts of sodium hexametaphosphate and 3 parts of sodium butyl p-hydroxybenzoate; the modified starch is prepared from phosphate starch and acetate starch in a ratio of 7:3.

[0029] The preparation method of the compound modified starch printing paste for the polyester comprises the following steps:

[0030] (1) Preparation of phosphate starch: Weigh starch, potassium dihydrogen phosphate, phosphoric acid and urea respectively according to the weight ratio of starch: potassium dihydrogen phosphate: phosphoric acid: urea = 80:7:5:4, and accurately weigh the The starch is placed in a vacuum esterification reaction tank, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com