Composite admixture with coal ash and slag powder and high-strength concrete made of same

A composite admixture and fly ash technology, applied in the field of high-strength concrete, can solve problems such as high cost, high energy consumption in production, and limited resources, and achieve the effects of fine particle size, improved strength in the later stage, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of composite admixture: the specific surface area is 500-800 m after mixing and grinding the secondary fly ash and S95 grade slag at a mass ratio of 7:3 2 / kg of admixture, denoted as CF.

[0023] The admixture prepared above is used to prepare concrete, and the admixture that is 43% of the quality of the cementitious material is used to replace cement; cement is P O42.5R ordinary silicate produced by Guangdong Yingde Conch Cement Co., Ltd. Cement; fine aggregate is Beijianghe sand from Xindu Sand and Stone Plant, Tanbu Town, Huadu District, fineness modulus Mx=2.84, and mud content 0.9%; coarse aggregate is 5-10mm melonite and Daya Bay produced in Zengcheng Stone Field The two-stage coarse aggregate of 5-20mm gravel produced in the quarry is combined into 5-20mm continuous graded aggregate; the water reducing agent is Kejie KJ-JS polycarboxylate high-performance water reducing agent.

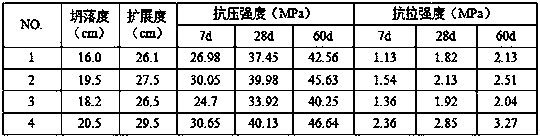

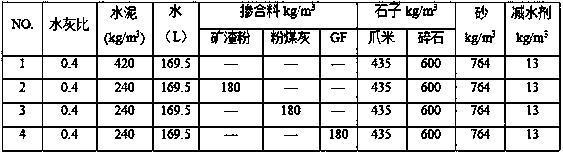

[0024] The mix ratio of this concrete is shown in Table 1, which is com...

Embodiment 2

[0031] Preparation of admixture: Mix and grind the secondary fly ash and S95 slag at a mass ratio of 6:4 to obtain a specific surface area of 500-800 m 2 / kg of admixture, denoted as CF.

[0032] The admixture prepared above is used to prepare concrete, and the admixture that is 43% of the quality of the cementitious material is used to replace cement; cement is P O42.5R ordinary silicate produced by Guangdong Yingde Conch Cement Co., Ltd. Cement; fine aggregate is Beijianghe sand from Xindu Sandstone Factory, Tanbu Town, Huadu District, fineness modulus Mx=2.84, mud content 0.9%; coarse aggregate is 5-10mm melonite and Daya Bay from Zengcheng Stone Field The two-stage coarse aggregate of 5-20mm gravel produced in the quarry is combined into 5-20mm continuous graded aggregate; the water reducing agent is Kejie KJ-JS polycarboxylate high-performance water reducing agent.

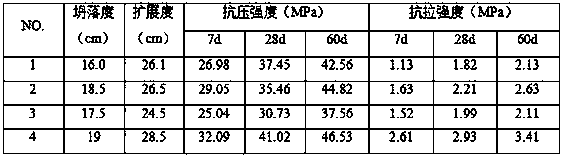

[0033] The mix ratio of this concrete is shown in Table 3, which is compared with pure cement concrete,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com