An experimental device for testing steam condensation law under heavy oil reservoir conditions, its working method and application

An experimental device and technology for heavy oil reservoirs, applied in the field of thermal recovery and development of heavy oil reservoirs, can solve the problems of complex condensation heat transfer, difficult steam condensation laws, and large differences in heat transfer characteristics, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

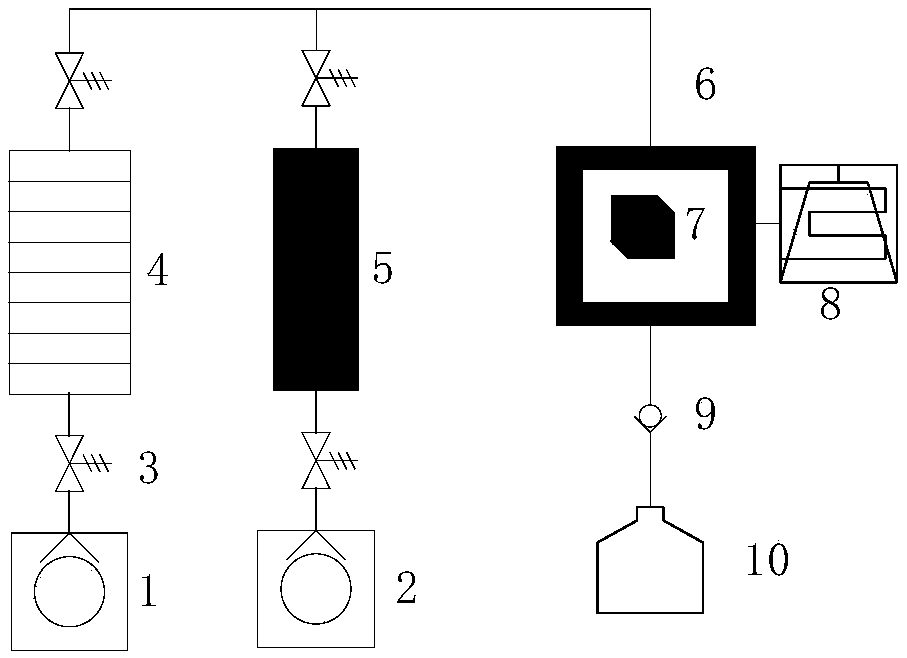

[0058] Such as figure 1 , 3 shown.

[0059] An experimental device for testing the law of steam condensation under the conditions of heavy oil reservoirs, comprising steam generation injection pipelines, injection pipelines for auxiliary production fluids, and a condensation chamber; the auxiliary production fluids are: nitrogen, carbon dioxide, flue gas, Viscosity solution or foaming agent solution etc.; In the present embodiment 1, only inject steam to described condensing chamber;

[0060] The steam generation injection pipeline and the injection pipeline of the auxiliary production fluid are respectively connected with the condensation chamber;

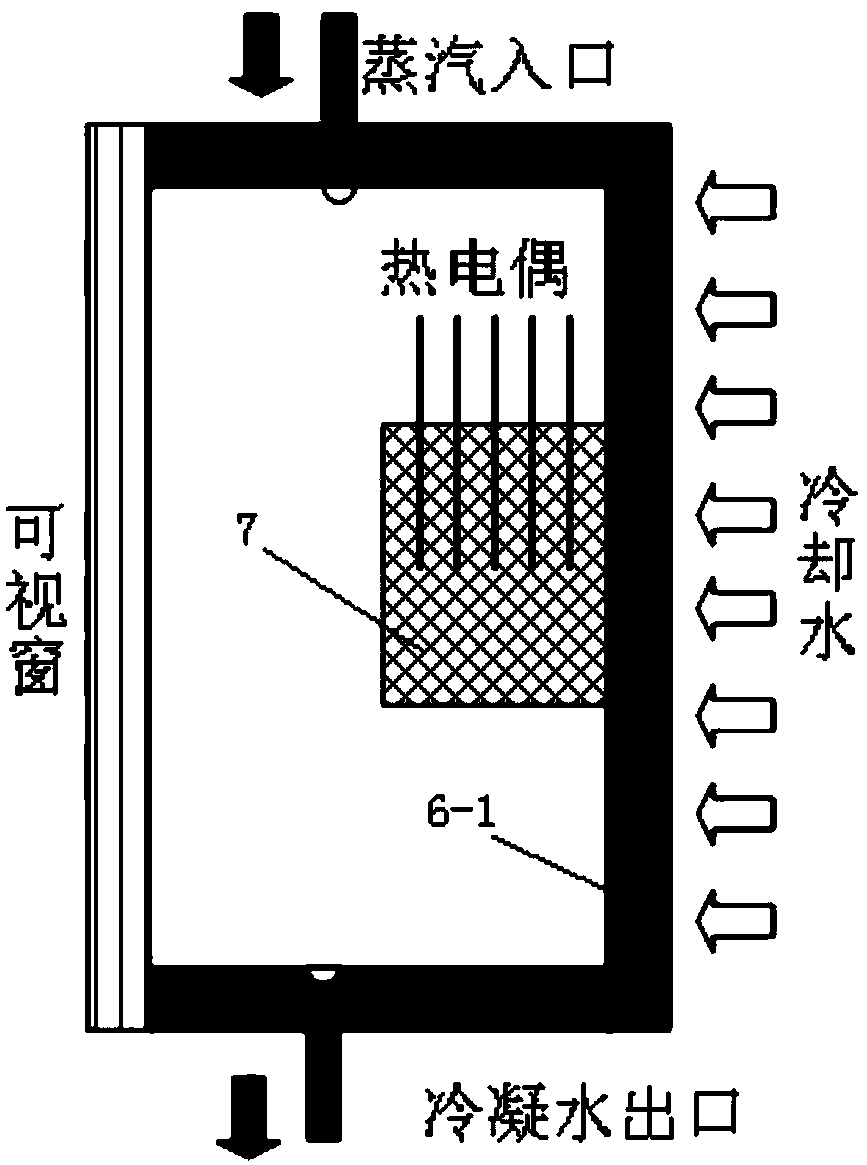

[0061] The condensation chamber includes a condensation installation wall, an observation window arranged opposite to the condensation installation wall, and a condensate collection channel is arranged at the bottom of the condensation chamber;

[0062] The steam generation injection pipeline and the injection pipeline of the a...

Embodiment 2

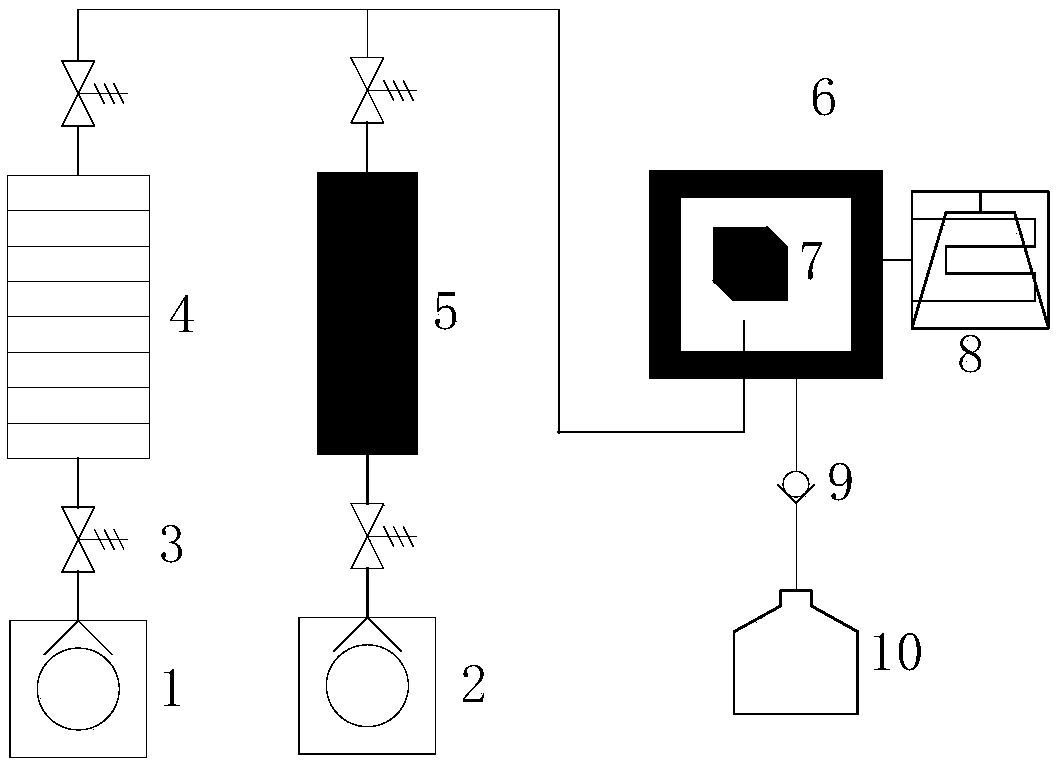

[0069] Such as figure 2 , 4 shown.

[0070] An experimental device for testing the law of steam condensation under the conditions of heavy oil reservoirs as described in Example 1, the difference is that the injection pipeline communicates with the bottom end of the condensation chamber 6, wherein the steam injection end It is placed under the end face of the experimental rock core 7, and the distance from the lower end face of the experimental rock core is 3 mm. The invention is designed to be connected from the bottom, and the steam is injected from the lower part and then contacts the experimental rock core to simulate the condensation phenomenon after the steam contacts the rock core in the development process of steam assisted gravity drainage (SAGD).

[0071] In the present invention, the high-precision plunger pump of the ISCO pump is used to respectively inject steam condensed steam and auxiliary production fluid into the condensation chamber through the steam gener...

Embodiment 3

[0073] The working method of experimental device as described in embodiment 1, comprises:

[0074] Installation before the experiment: Select the experimental core according to the heavy oil formation environment to be simulated and saturate the formation water and heavy oil, wherein the experimental core is an underground core core of a heavy oil reservoir, and then cut the core core by a core cutting machine Become a square experimental core 7 of 20mm×20mm×24mm; vacuumize the experimental core 7, saturate the formation water, measure the permeability, and the permeability is 1.5μm 2 , is saturated with heavy oil in the target reservoir, and the initial oil saturation is 0.65;

[0075] The above-mentioned treated experimental core is installed on the condensation installation wall of the condensation chamber, and a plurality of temperature sensors are distributed in the experimental core to monitor the temperature distribution and temperature change of the experimental core d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com