Degradable wire and its preparation method

A technology of wires and conductive parts, applied in the field of wires, can solve the problem of non-degradable wires, etc., and achieve the effects of wide source, avoiding secondary surgery and alleviating pain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

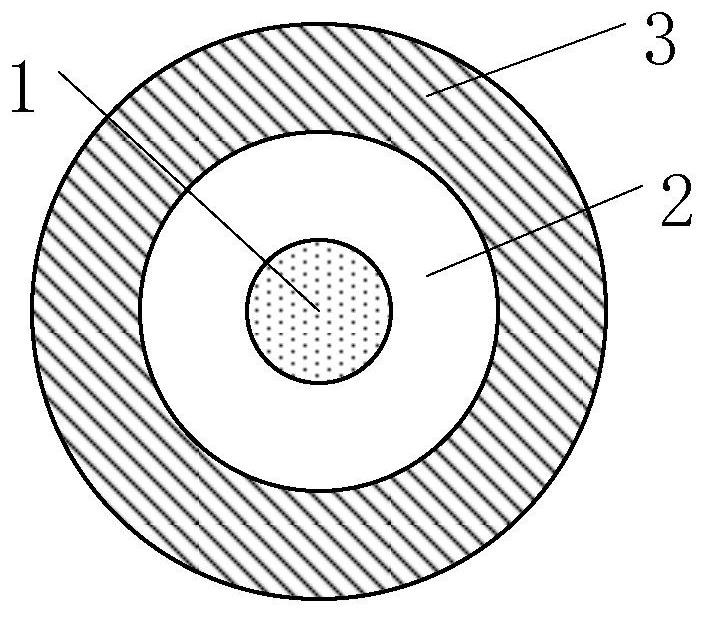

[0052] In the first embodiment of the present invention, a degradable wire is provided. figure 1 It is a schematic structural diagram of the degradable wire according to the first embodiment of the present invention. Please refer to figure 1 , the degradable wire in this embodiment includes:

[0053] A matrix 1 comprising absorbable medical sutures;

[0054] The conductive part 2, including a degradable metal layer, wraps the outer surface of the substrate; and,

[0055] The protection part 3 includes a degradable polymer material layer for encapsulating the conductive part.

[0056] Specifically, the absorbable medical sutures include: sheep catgut (ordinary catgut, chrome catgut), pure natural collagen sutures, chemical synthetic threads (PGA, PGLA, PLA) and the like.

[0057] Furthermore, since the absorbable medical suture has good plasticity, it can be straightened before wrapping the metal.

[0058] The material of the degradable metal layer is a pure metal material...

no. 3 example

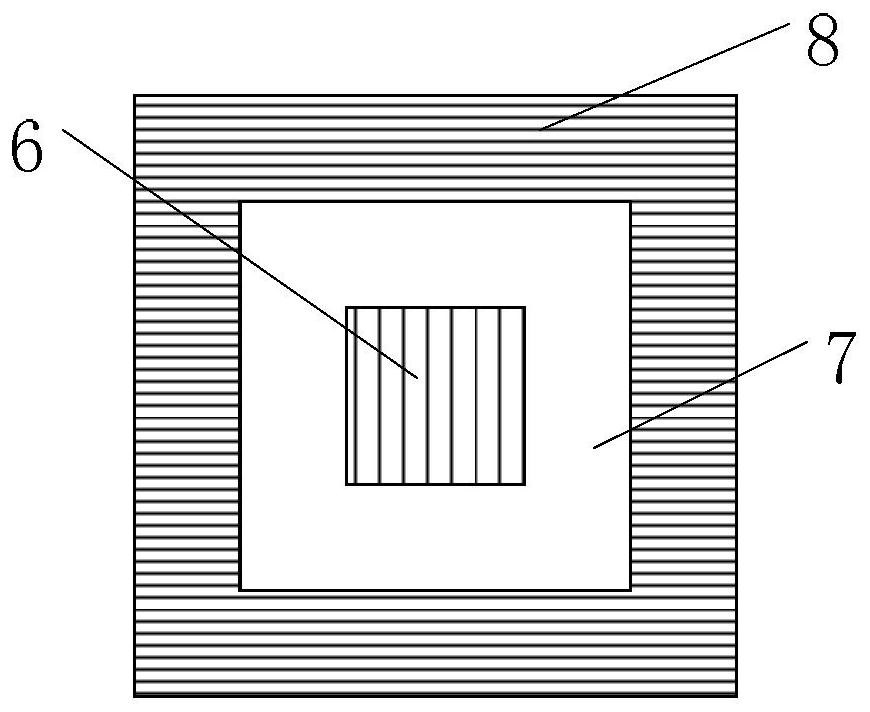

[0077] In the third embodiment of the present invention, a degradable wire is provided. image 3 It is a schematic structural diagram of the degradable wire according to the third embodiment of the present invention. Please refer to image 3 , the degradable wire in this embodiment includes:

[0078] The matrix 6 includes degradable polymer wires;

[0079] The conductive part 7, including a degradable metal layer, wraps the outer surface of the substrate; and,

[0080] The protection part 8 includes a degradable polymer material layer for encapsulating the conductive part.

[0081] Specifically, the degradable polymer wire can be obtained from the prepared polymer film by cutting.

[0082] The degradable metal layer adopts pure metal materials or metal alloys, including pure magnesium and magnesium-based alloys, pure iron and iron-based alloys, pure zinc and zinc-based alloys, tungsten and (calcium-based, zinc-based and strontium-based) bulk Amorphous alloys, etc.

[008...

no. 5 example

[0103] Please refer to Figure 5 , the preparation method of the degradable wire in this embodiment includes:

[0104] Using degradable metal wires to form the matrix of degradable wires;

[0105] A degradable polymer material layer is packaged outside the degradable metal wire, that is, a protective part of the degradable wire is formed.

[0106] Since the degradable polymer material exists in solid form, the encapsulation of the metal layer by the degradable polymer material can be completed through processes such as solvent dissolution and solvent volatilization.

[0107] Advantageously, the material treatment methods used in the experiment can be chemical etching, filing, surface plasma treatment, etc., and the metal wires are completely exposed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com