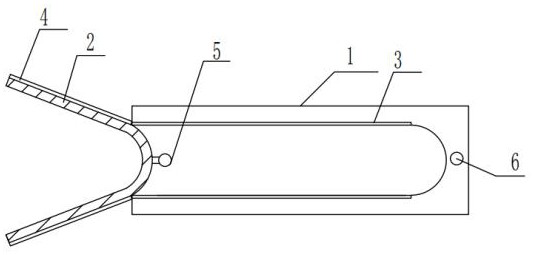

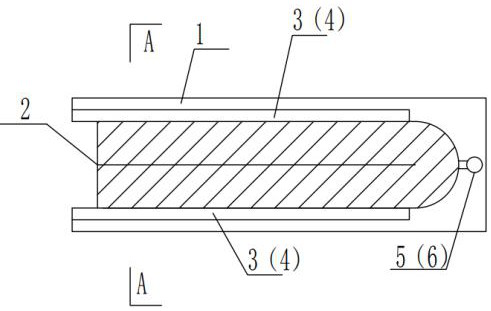

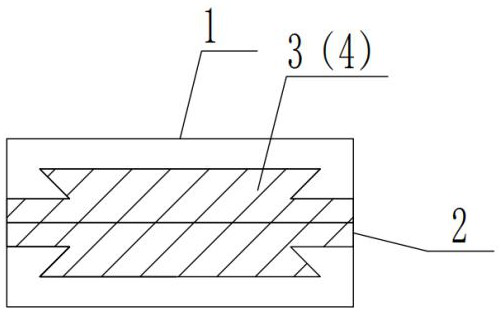

Absorbable macromolecule hemostatic clip

A hemostatic clip and polymer technology, applied in wound clips, medical science, surgery, etc., can solve the problem that the hemostatic titanium clip cannot be degraded, and achieve excellent degradability, firm structure, and good fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of described hemostatic clip, comprises the steps:

[0033] S1. Preparation of raw materials

[0034] (a) Preparation of polyglycolide:

[0035] Under vacuum or high pressure conditions, set the reaction temperature at 120-180°C, take a certain amount of glycolide in the reaction kettle, add 0.01-0.05% mass concentration of stannous octoate catalyst, the reaction time is 5-7h, and then reflux to purify and produce Granules to obtain polyglycolide, which should be stored in a refrigerator at low temperature and sealed;

[0036] (b) Preparation of polyglycolide-polytrimethylene carbonate-polydioxanone copolymer:

[0037] Under vacuum or high pressure conditions, set the reaction temperature at 110-200°C, take a certain amount of glycolide, trimethylene carbonate, and p-dioxanone in the reaction kettle, and add 0.01-0.05% mass concentration of stannous octoate Catalyst, glycolide: trimethylene carbonate: the weight ratio of dioxanone is (15:5:80)-...

Embodiment 1

[0046] Preparation of polyglycolide: take 200g glycolide in a reaction kettle, add 0.01% mass concentration of stannous octoate catalyst, then add a certain amount of acetone to adjust the viscosity of the system, and set the reaction temperature at 170°C under vacuum conditions. 6h to obtain polyglycolide product. The polyglycolide product is fed into an extruder, and the extruding temperature is 150° C. to obtain polyglycolide particles with a particle diameter of 1.5-2 mm and a length of 3 mm. The polyglycolide particles were vacuum dried at 40°C for 24 hours. The test condition was set at 230° C. / 2.16 kg by means of a melt index instrument, and the melt index of polyglycolide measured by ASTM D-1238 standard was 50 g / 10 min.

[0047] The polyglycolide prepared above is processed into the outer clip of the hemostatic clip through the injection molding process of the present invention, and the tensile strength of the outer clip is tested to be 70 MPa and the molecular weigh...

Embodiment 2

[0051] The preparation of polyglycolide-polytrimethylene carbonate-polydioxanone copolymer: in reactor, add 300g glycolide, trimethylene carbonate, p-dioxanone (by weight 15:25:60), adding 0.05% mass concentration of stannous octoate catalyst, reaction temperature 135 ° C, nitrogen protection, reaction time 6 h, and then reflux purification, at 170 ° C, the obtained polyglycolide-poly Sanya Methylcarbonate-polydioxanone copolymer product joins in extruder, obtains particle diameter and is 1.5-2mm, is long the particle of 3mm size, weighs and obtains pellet 280g, yield 93%, will The above pellets were dissolved in hexafluoroisopropanol solution, and the intrinsic viscosity of polyglycolide-polytrimethylene carbonate-polydioxanone copolymer was measured with an Ubbelohde viscometer in a constant temperature water bath at 25°C. The number is 3.60dL / g.

[0052] The polyglycolide-polytrimethylene carbonate-polydioxanone copolymer prepared above is processed into the inner layer cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com