Preparation method and application of functional carbon nanotube loaded Pd catalyst

A technology of carbon nanotubes and catalysts, which is applied in the field of preparation of functionalized carbon nanotube-supported Pd catalysts, can solve the problems that carbon-based catalysts have not been reported, and achieve remarkable catalytic oxidation performance, cheap equipment raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

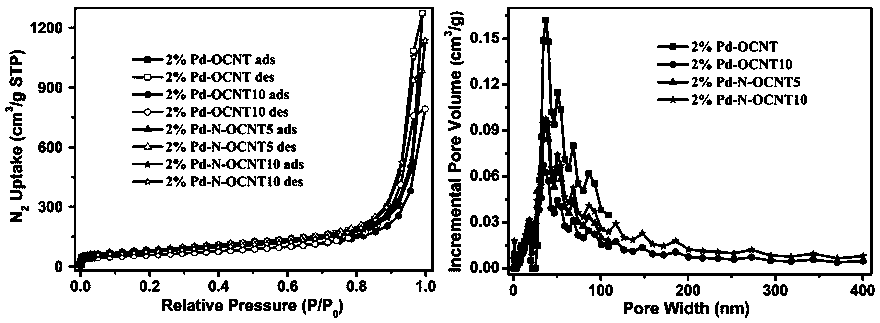

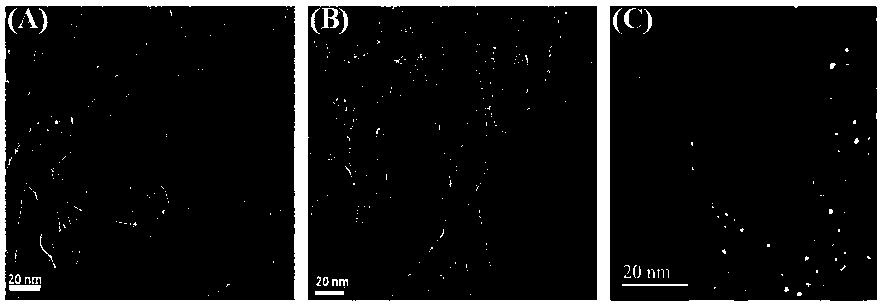

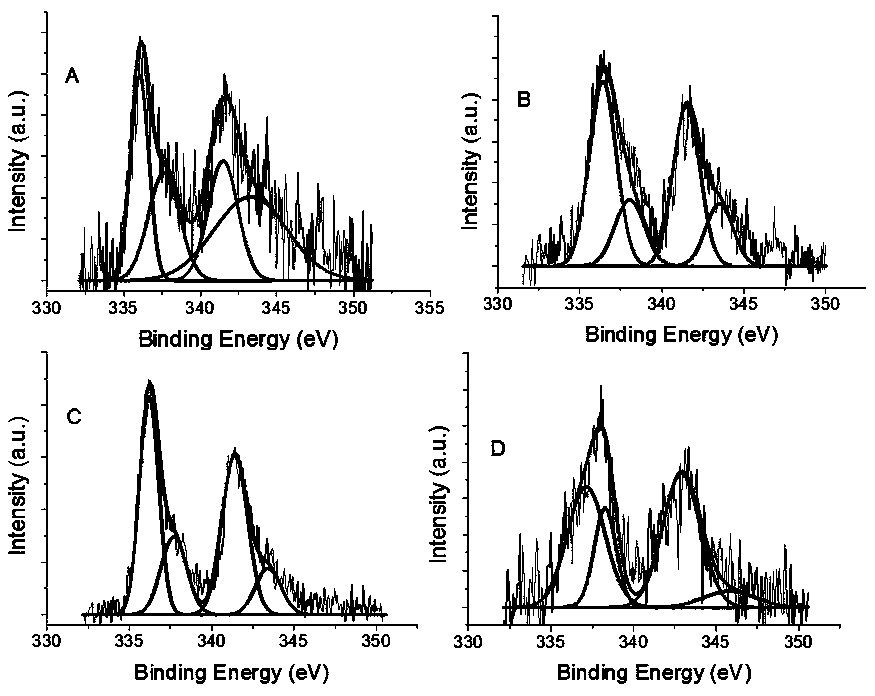

[0031] Acidification of carbon nanotubes: Mix 10 g of carbon nanotubes with 400 mL of 68 wt% concentrated nitric acid, reflux at 110 °C for 4 hours, cool to room temperature, wash with distilled water until neutral, dry at 80 °C, and then grind Stored as powder for later use, the sample is marked as OCNT;

[0032] Modified carbon nanotubes: Dissolve 0.08 g of citric acid, add drop by drop to 1 g of OCNT by impregnation, stir until uniform at room temperature, dry and heat in a pre-set blast oven at 180°C for 40 hours ; After cooling down to room temperature, wash with distilled water for 3 times, dry at 80°C and store for later use; the sample is marked as OCNT2;

[0033] Nitrogen-doped modified carbon nanotubes: Dissolve 0.25 g of urea in 10 mL of water, add dropwise to 0.5 g of the above-mentioned modified carbon nanotubes, transfer to the polytetrafluoroethylene liner of the hydrothermal kettle, seal it, and put it in the pre- Set it in a blast oven at 180°C, heat it for 8...

Embodiment 2

[0036] Acidification of carbon nanotubes: Mix 10 g of carbon nanotubes with 400 mL of 68 wt% concentrated nitric acid, reflux at 100 °C for 4 hours, cool to room temperature, wash with distilled water until neutral, dry at 80 °C, and then grind Stored as powder for later use, the sample is marked as OCNT;

[0037] Modified carbon nanotubes: dissolve 0.2 g of citric acid, add dropwise to 1 g of OCNT by impregnation, stir until uniform at room temperature, dry and heat in a pre-set blast oven at 180°C for 40 hours ; After cooling down to room temperature, wash 5 times with distilled water, dry at 80°C and store for later use; the sample is marked as OCNT5;

[0038] Nitrogen-doped modified carbon nanotubes: Dissolve 0.25 g of urea in 10 mL of water, add dropwise to 0.5 g of the above-mentioned modified carbon nanotubes, transfer to the polytetrafluoroethylene liner of the hydrothermal kettle, seal it, and put it in the pre- Set it in a blast oven at 180°C, heat it for 8 hours; a...

Embodiment 3

[0041] Acidification treatment of carbon nanotubes: 10 g carbon nanotubes were mixed with 400 mL of 68 wt% concentrated nitric acid, refluxed at 120 °C for 4 hours, cooled to room temperature, washed with distilled water until neutral, dried at 80 °C, and then ground Stored as powder for later use, the sample is marked as OCNT;

[0042] Modified carbon nanotubes: dissolve 0.4 g of citric acid, add dropwise to 1 g of OCNT by impregnation, stir until uniform at room temperature, dry and heat in a pre-set blast oven at 180°C for 40 hours ; After cooling down to room temperature, wash with distilled water 4 times, dry at 80°C and store for later use; the sample is marked as OCNT10;

[0043] Nitrogen-doped modified carbon nanotubes: Dissolve 0.25 g of urea in 10 mL of water, add dropwise to 0.5 g of the above-mentioned modified carbon nanotubes, transfer to the polytetrafluoroethylene liner of the hydrothermal kettle, seal it, and put it in the pre- Set it in a blast oven at 180°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com