Corn crushing device for agricultural production

A pulverizing device and corn technology, applied in the field of agricultural machinery, can solve the problems of short shelf life, unfavorable storage, and increased cost, and achieve the effects of ensuring quality, reducing humidity and prolonging storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

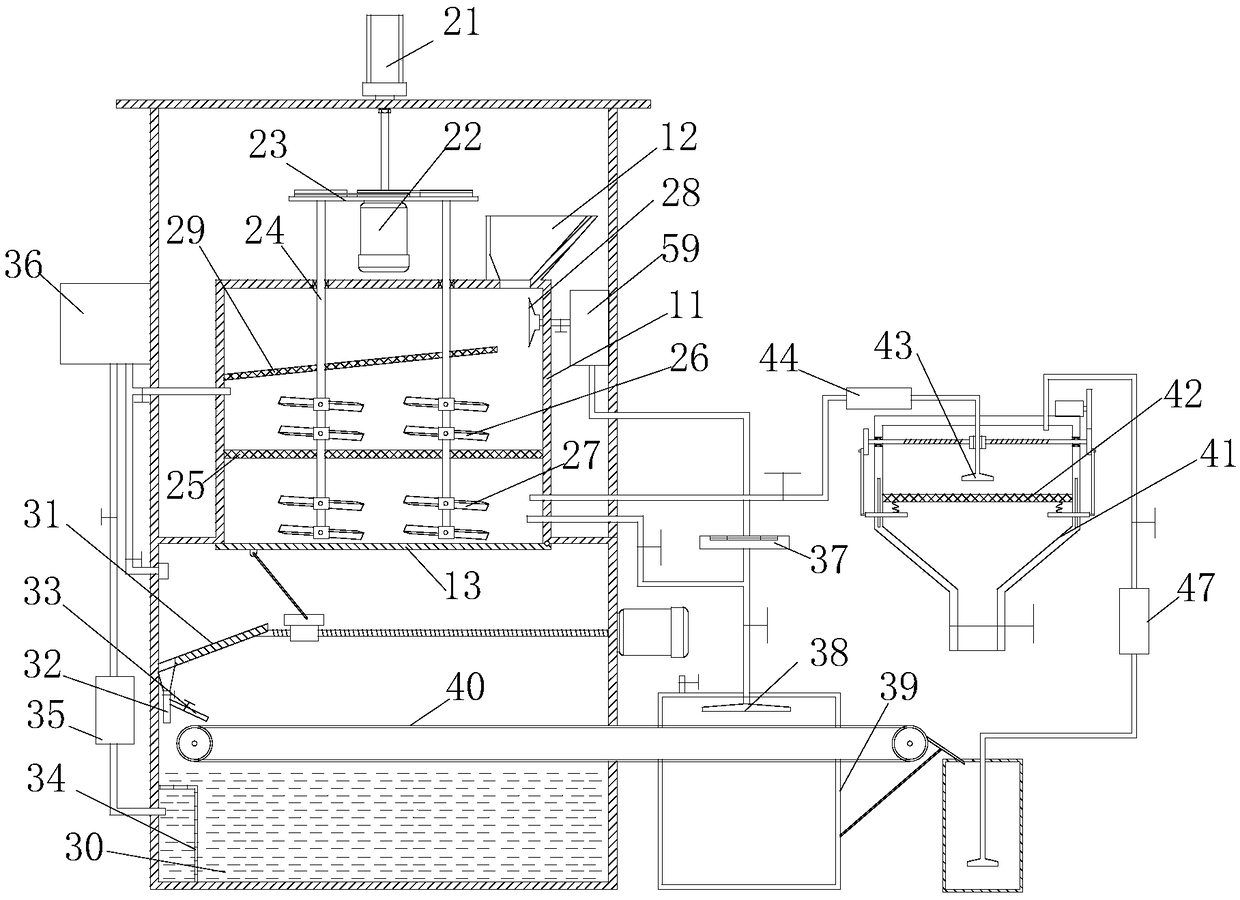

[0049] refer to figure 1 , this embodiment proposes a corn grinding device for agricultural production, the grinding device sequentially includes a crushing unit, a drying unit and a recycling unit in the order of the process flow.

[0050] The crushing unit includes a crushing box 11 , a rotating shaft 24 , an impurity removal mechanism arranged in the crushing box 11 , an upper crushing mechanism and a lower crushing mechanism.

[0051] The top of the scrap box 11 has a feed inlet and an upper insertion opening for vertically inserting the rotating shaft 24 , and the bottom of the scrap box 11 has a discharge opening. The discharge port is hinged with a material door 13, and the material door 13 is used to close the discharge port of the crushed material box 11. The material door 13 is connected with the feeding power mechanism, and can be powered by the feeding power. The mechanism is driven to perform flipping motion.

[0052] The impurity removal mechanism includes an u...

Embodiment 2

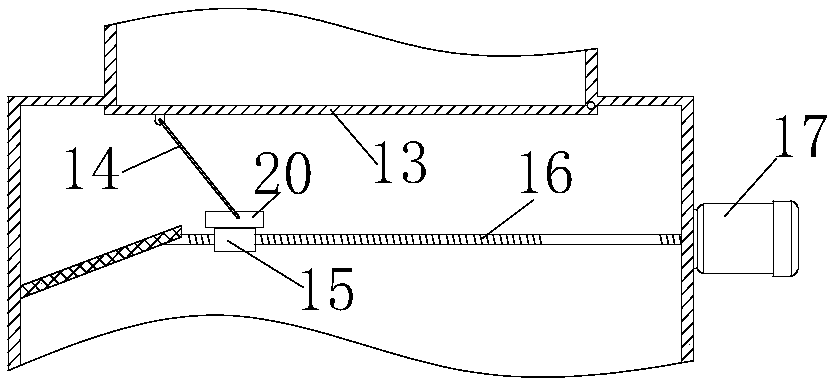

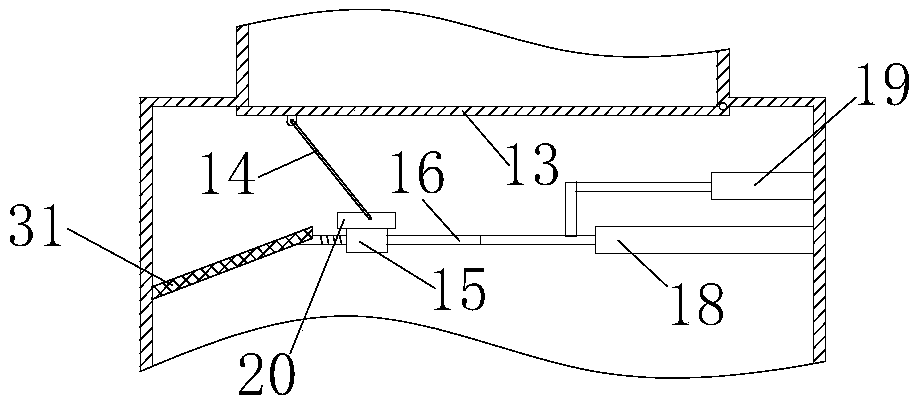

[0070] refer to figure 2 , 3 , The difference between this embodiment and Embodiment 1 is that the feeding power mechanism includes a feeding rod 14 and a movable block 20, and the two ends of the feeding rod 14 are respectively hinged on the material gate 13 and the movable block 20 , the movable block 20 is located below the material door 13, and the movable block 20 is connected with the first power mechanism or the second power mechanism for horizontal movement.

[0071] refer to figure 2 , 4, the first power mechanism includes a telescopic rod 18 and a blanking cylinder 19, the movable block 20 is connected to the telescopic end of the telescopic rod 18, and the telescopic end of the telescopic rod 18 is connected to the piston end of the blanking cylinder 19.

[0072] On the premise that the movable block 20 is connected to the first power mechanism, when it is necessary to open or close the discharge port of the crushed material box 11, the telescopic rod 18 is dri...

Embodiment 3

[0077] refer to Image 6 , 7 The difference between this embodiment and Embodiment 1 is that the drying unit includes a drying box 39, and the drying box 39 is provided with a belt inlet and a belt outlet for the conveyor belt 40 to pass in and out horizontally. Described drying box 39 is provided with drying pipe 38, and the axial direction of described drying pipe 38 is consistent with the conveying direction of described conveyor belt 40, and described drying pipe 38 is provided with a plurality of air outlets along its axial direction, and described drying pipe 38 It is connected with the air supply mechanism 59 through a pipeline, and the pipeline between the drying pipe 38 and the air supply mechanism 59 is connected with an electric heating box 37, and the inlet of the electric heating box 37 is connected with the air supply mechanism 59. The electric heating box 37 has two outlets, one of which is connected to the drying pipe 38, and the other outlet extends into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com