O-alkyl-S-hydroxyalkyl-xanthate collecting agent, and preparation and application thereof

A xanthate ester and collector technology, applied in solid separation, flotation, etc., can solve the problems of unsatisfactory selectivity and dispersibility, achieve excellent flotation performance, increase carbon chain length, and enhance floatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: Preparation of O-isopropyl-S-hydroxyethyl xanthate

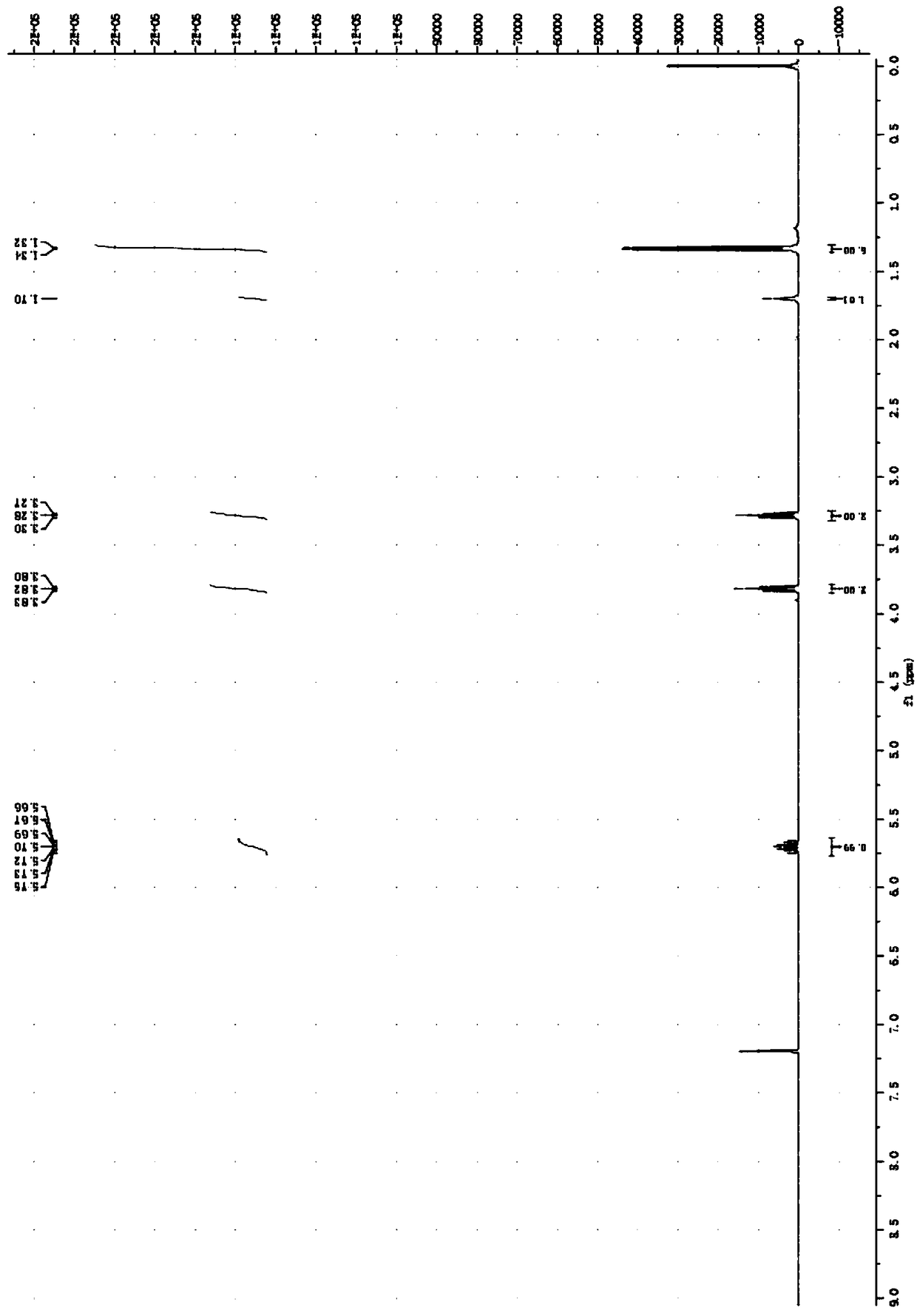

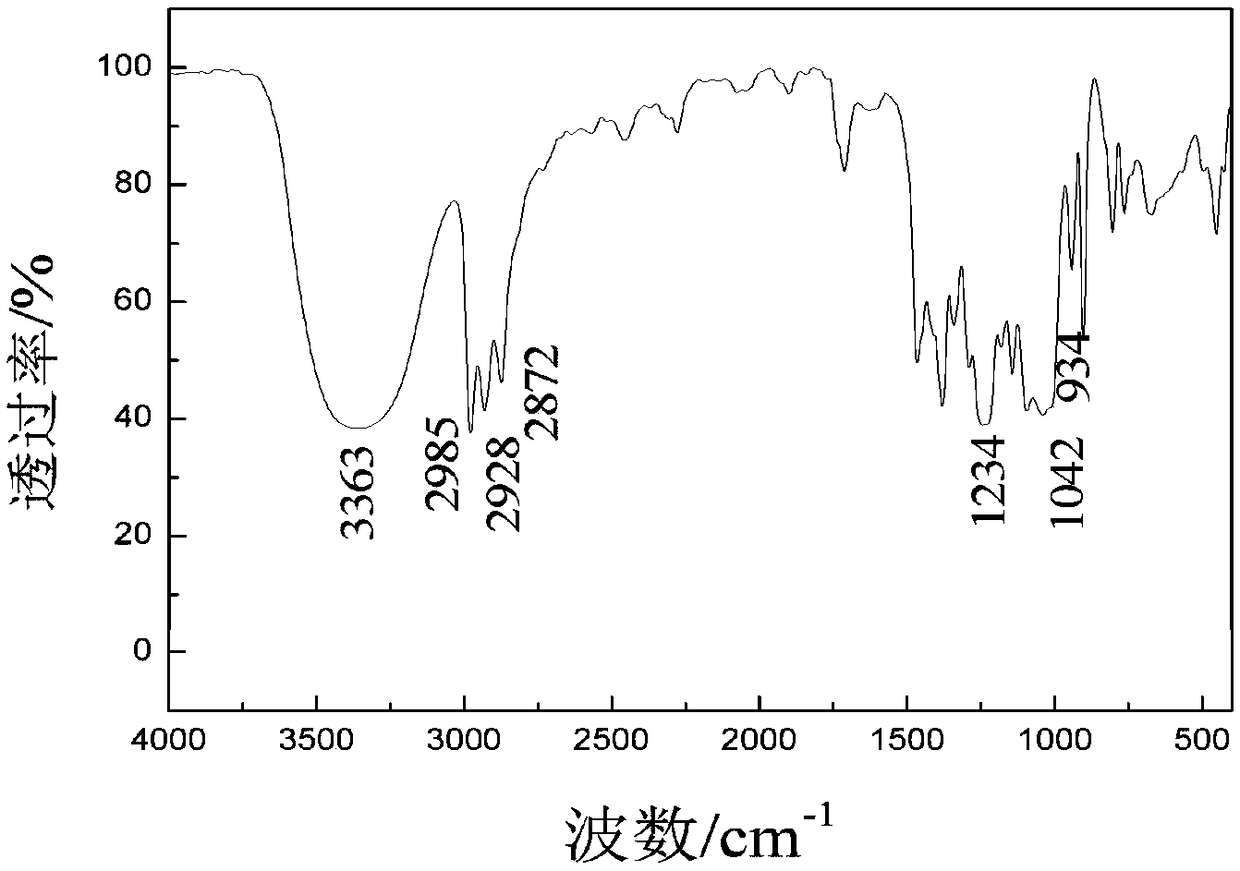

[0059] Add 8.13 parts of 2-chloroethanol with a purity of 99% into the reactor, add 18.9 parts of sodium isopropylxanthate with a purity of 83.54% in batches, stir while adding, then add 15 parts of distilled water, and heat up to the bottle The temperature is 60°C, after 5 hours of constant temperature reaction, cool to room temperature, and separate the liquid to obtain the oil phase O-isopropyl-S-hydroxyethyl xanthate. The analysis shows that O-isopropyl-S-hydroxyethyl xanthate The yield of acid ester was 88.3%. When the reaction does not add distilled water as a solvent, the yield of the product O-isopropyl-S-hydroxyethyl xanthate is 68.75%. After the product is purified by column chromatography, the O-isopropyl-S-hydroxyethyl xanthate 1 HNMR picture as shown figure 1 As shown, the infrared spectrum is shown in image 3 shown.

Embodiment 2

[0060] Embodiment 2: the preparation of O-isobutyl-S-hydroxyethyl xanthate

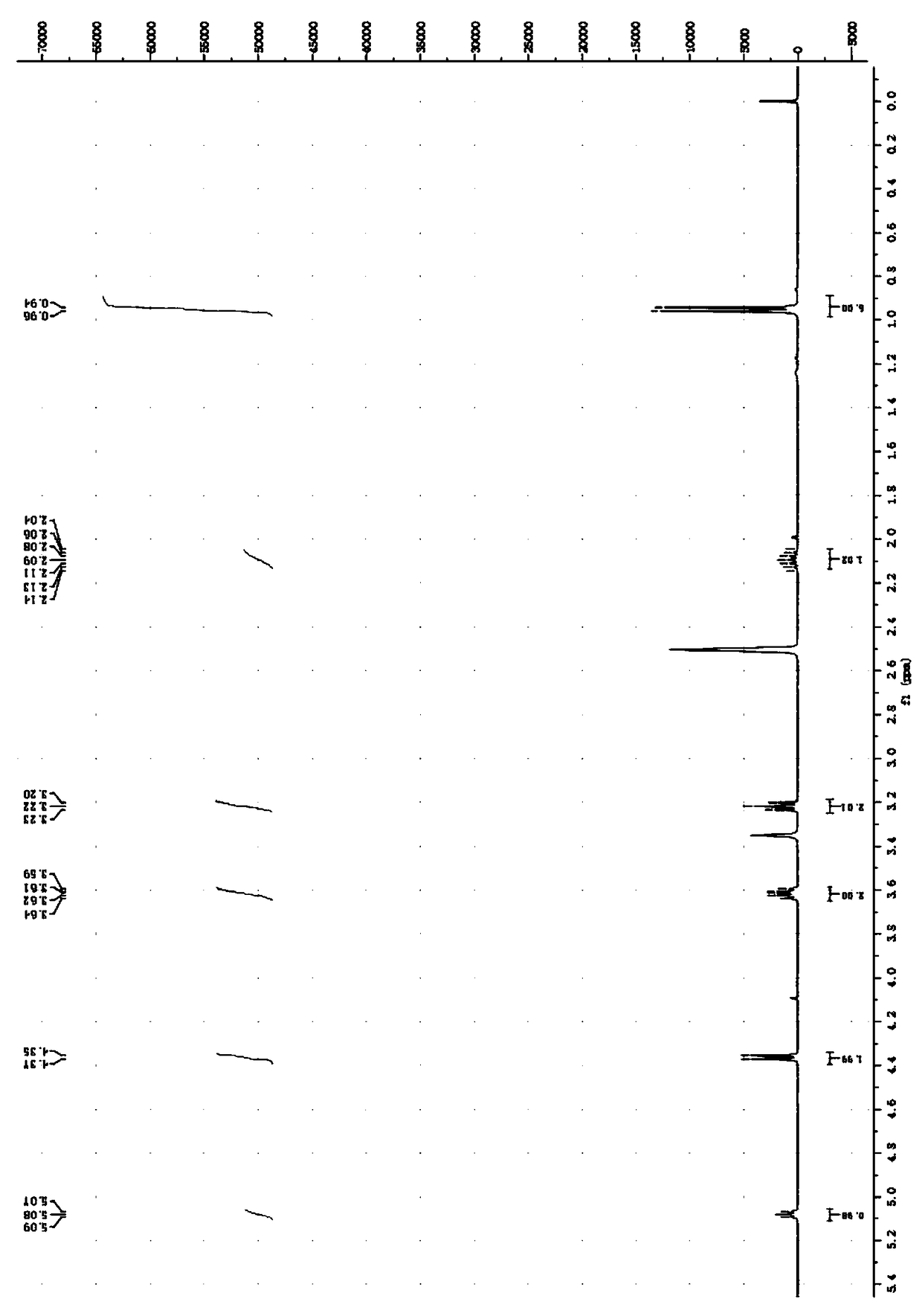

[0061] Add 8.13 parts of 2-chloroethanol with a purity of 99% into the reactor, add 19.32 parts of sodium isobutyl xanthate with a purity of 89.0% in batches, stir while adding, then add 15 parts of distilled water, and heat up to the bottle The temperature is 50°C, after 7 hours of constant temperature reaction, cool to room temperature, and separate the liquid to obtain the oil phase O-isobutyl-S-hydroxyethyl xanthate. The analysis shows that O-isobutyl-S-hydroxyethyl xanthate The yield of acid ester was 78.2%. When the reaction time is 3 hours, the yield of the product O-isobutyl-S-hydroxyethyl xanthate is 23.20%. O-isobutyl-S-hydroxyethyl xanthate 1 HNMR picture as shown figure 2 As shown, the infrared spectrum is shown in Figure 4 shown.

Embodiment 3

[0062] Embodiment 3: the preparation of O-n-butyl-S-hydroxyethyl xanthate

[0063] Add 8.13 parts of 2-chloroethanol with a purity of 99% into the reactor, add 18.7 parts of sodium n-butyl xanthate with a purity of 92.1% in batches, stir while adding, then add 15 parts of distilled water, and heat up to the bottle The temperature is 50°C, after 7 hours of constant temperature reaction, cool to room temperature, and separate the liquid to obtain the oil phase O-isobutyl-S-hydroxyethyl xanthate. The analysis shows that O-isobutyl-S-hydroxyethyl xanthate The yield of acid ester is 77.34%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com