Automatic cleaning device of surface of photovoltaic battery panel array

A photovoltaic panel and automatic cleaning technology, which is applied in photovoltaic power generation, photovoltaic modules, cleaning flexible objects, etc., can solve the problems of backward cleaning methods, inconvenient dust removal, and high cost, and achieve simple structural design, reduced maintenance costs, and low manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

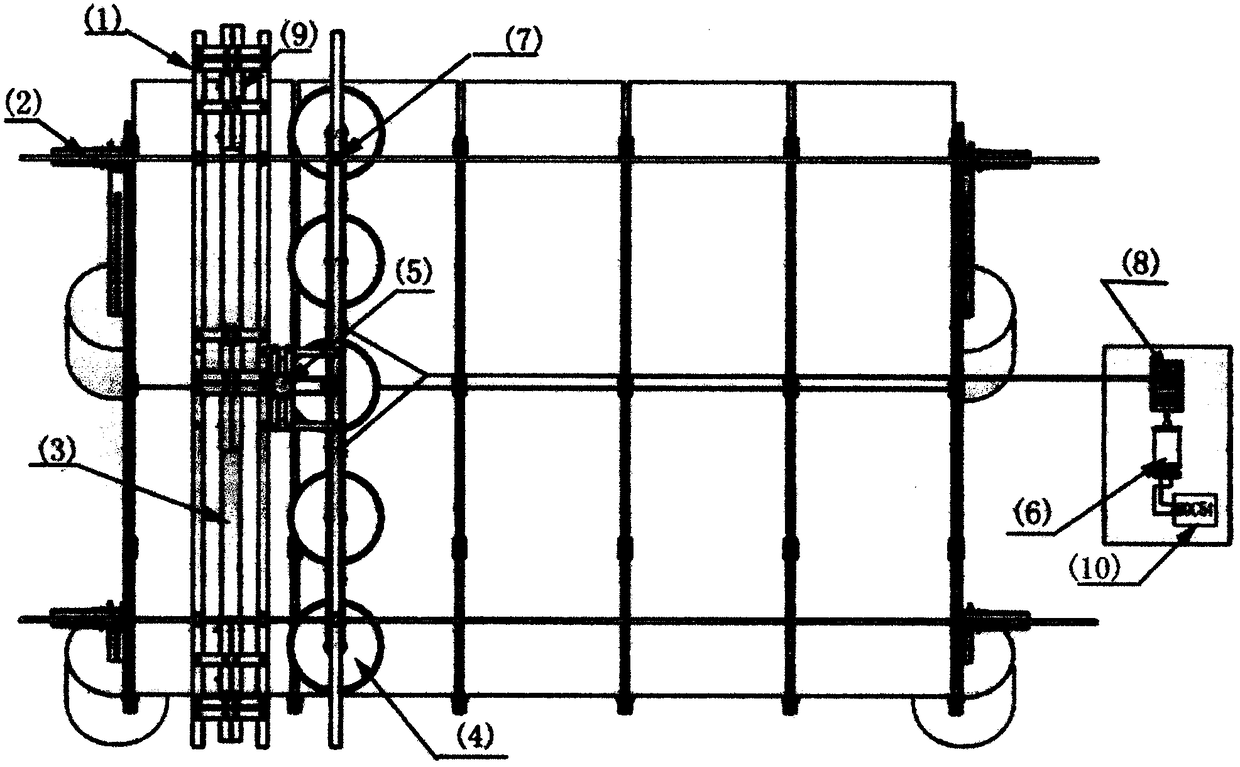

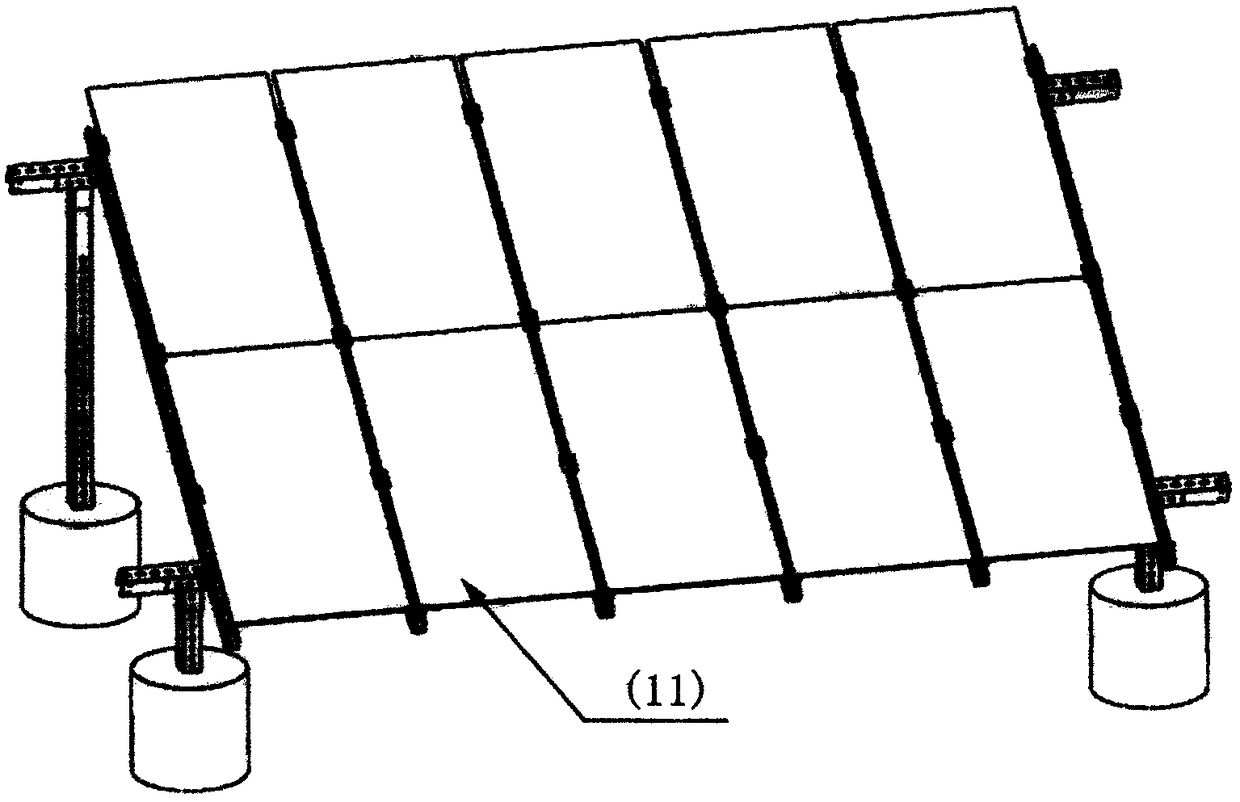

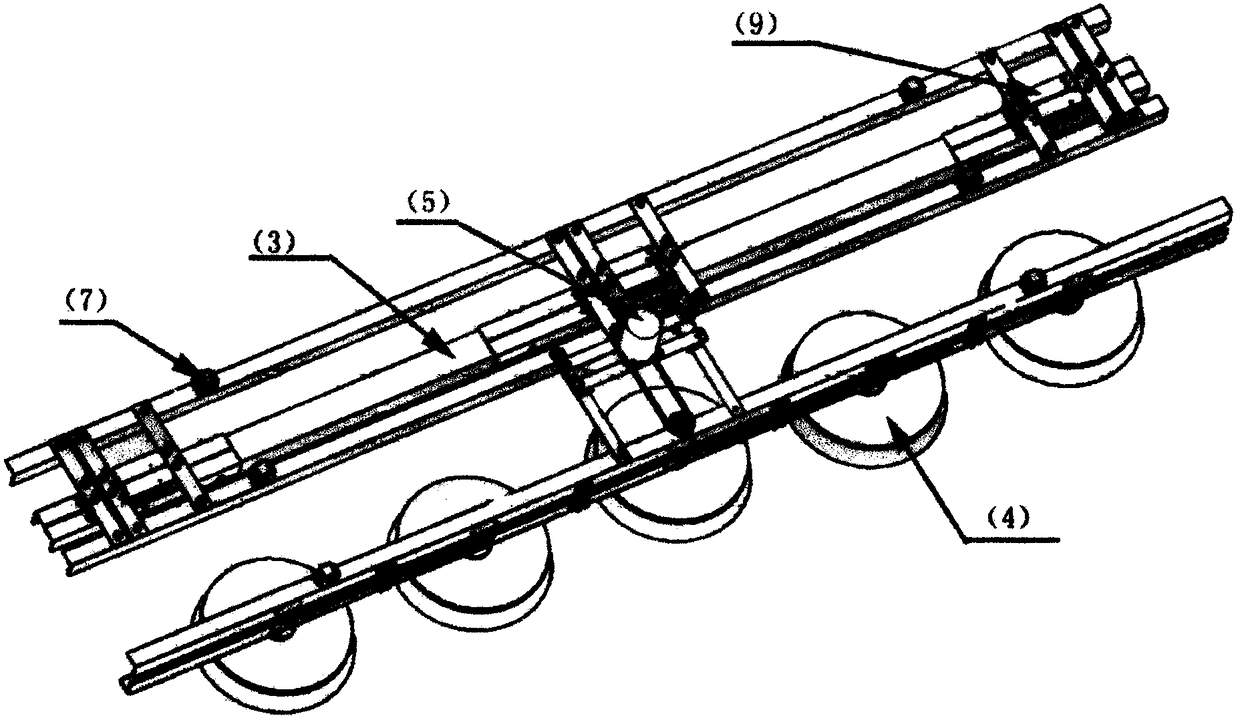

[0030] When in use, it can be installed on the surface of the photovoltaic array. The specific implementation steps: two guide rails 2 are installed in parallel on both ends of the shelf through corresponding connecting devices, and the height from the surface of the battery panel is adjustable; the composite strip brush 3 of the cleaning device, The disc brush 4 is in contact with the surface of the battery board, and the surface of the battery board supports the whole device. There are 6 sliders fixed on the frame, and the device can slide smoothly on the guide rail 2 through the sliders; the traction motor 6 is horizontal and installed On the support frame on one side of the photovoltaic array; other structural installation forms are shown in the attached drawings.

[0031] The control mode of the present invention is divided into automatic control and manual control. The automatic control is through the start and stop of the automatic control device of the single chip micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com