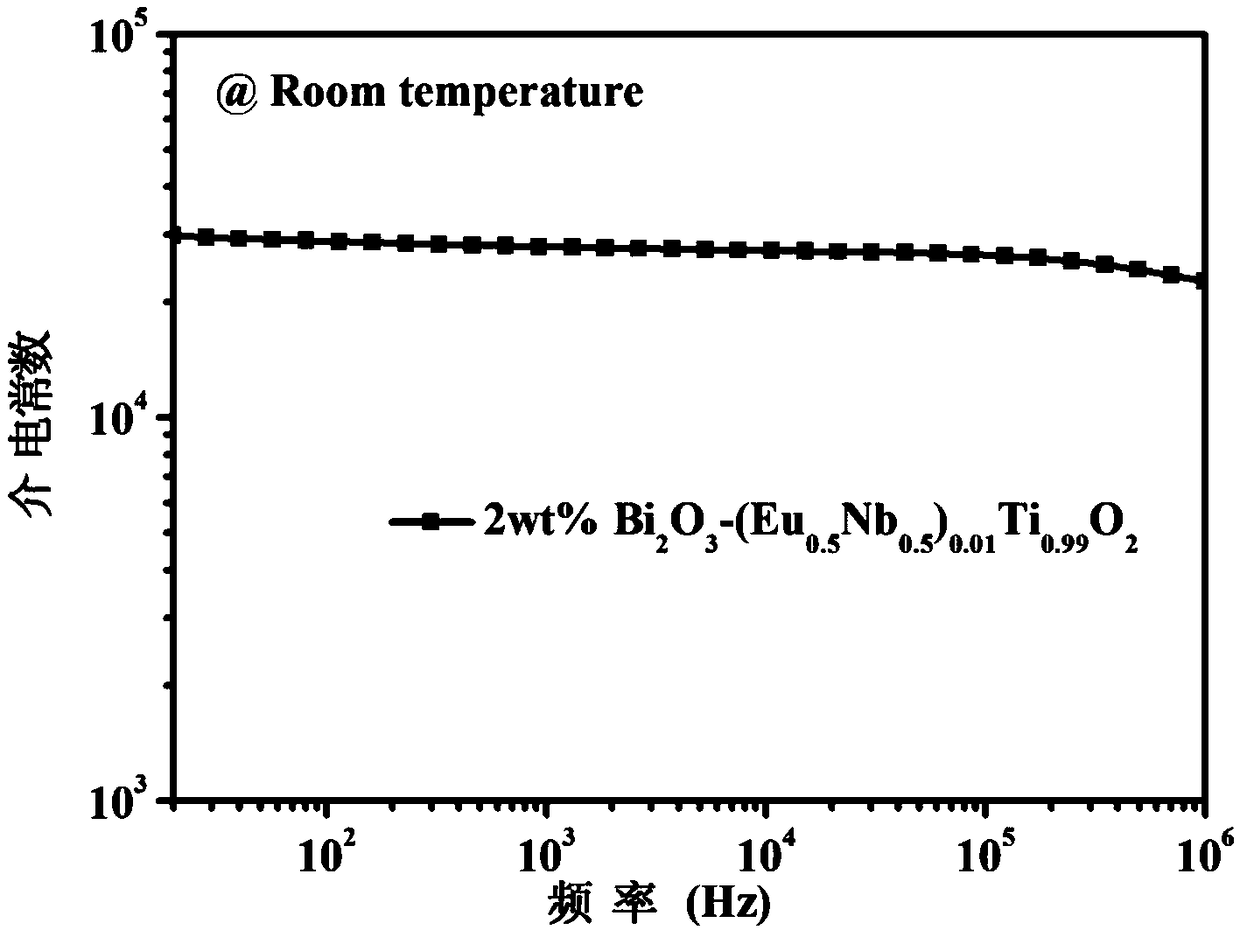

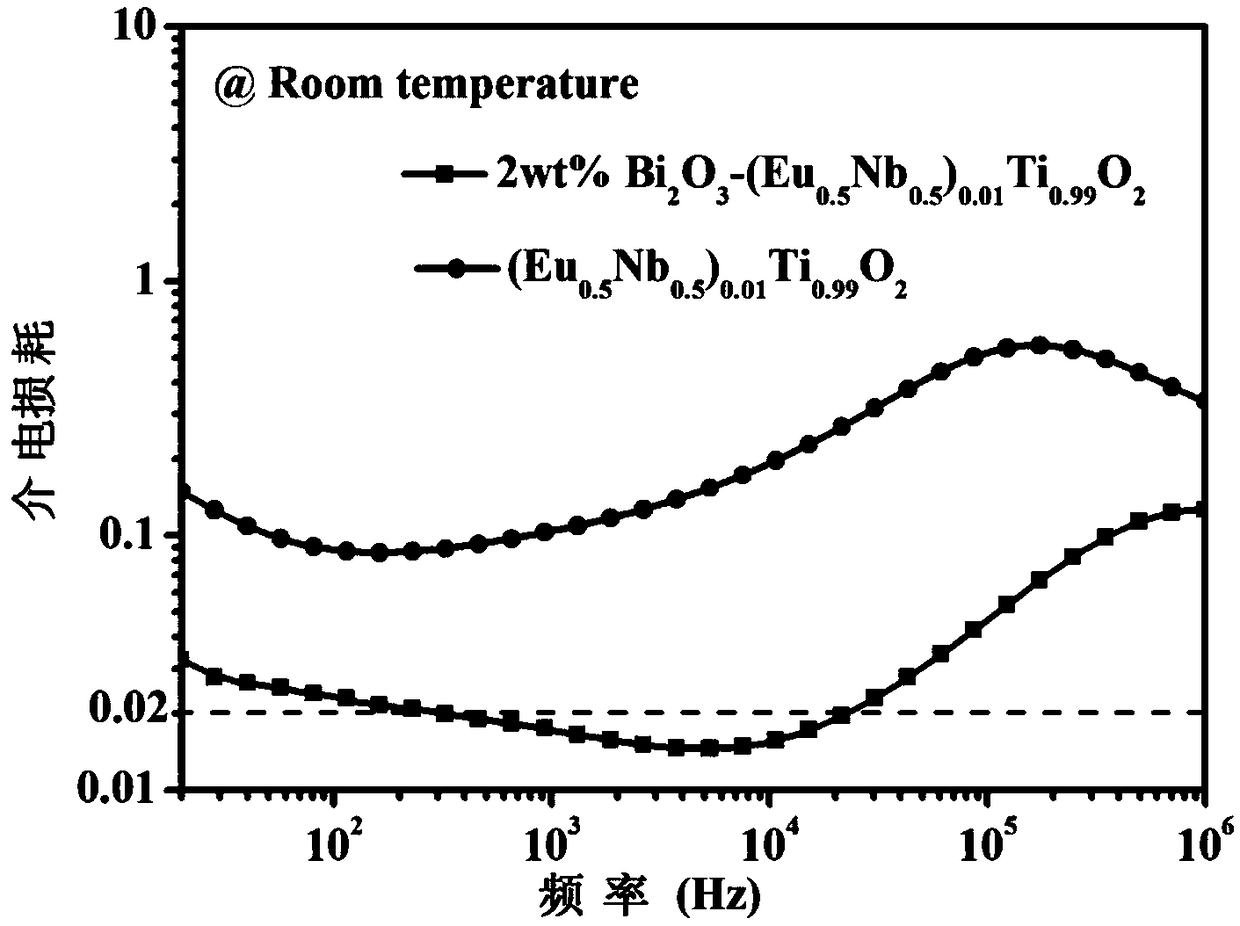

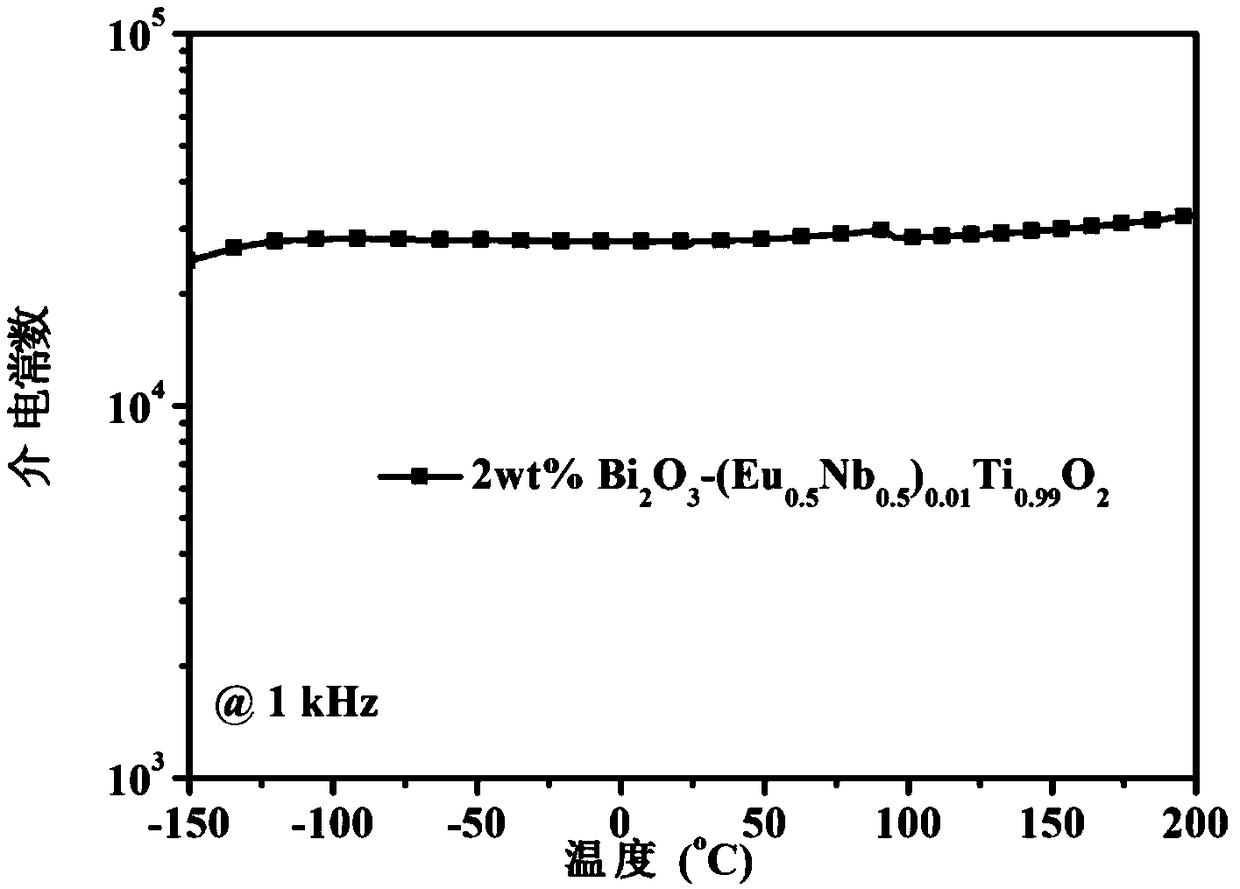

Ultralow-dielectric loss high-dielectric constant ceramic dielectric material and preparation method thereof

A technology of ceramic dielectric materials and high dielectric constant, applied in the field of electronic ceramics, can solve the problems of large dielectric loss, etc., and achieve the effect of reducing dielectric loss, increasing dielectric constant, and rich resource content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Its preparation method comprises the following steps:

[0027] (1) According to the chemical formula (Eu 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 , Europium oxide, niobium oxide and titanium dioxide were wet ball milled, dried and kept at 1200°C for 2 hours to obtain (Eu 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 Ceramic powder.

[0028] (2) will Bi 2 o 3 powder and (Eu0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 Ceramic powder xwt% Bi according to the chemical formula 2 o 3 -(100-x)wt%(Eu 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 For batching, among them, 0<x≤3, after wet ball milling, drying, pre-firing and molding, heat preservation at 1350-1500°C for 2-6h and sinter into porcelain to obtain ultra-low dielectric loss and high dielectric constant ceramic dielectric materials.

[0029] The ball milling medium of the wet ball milling in the step (1) and the step (2) is absolute ethanol, and the ball stone is zirconia ball stone.

[0030] The ball milling time of the wet ball milling in the step (...

specific Embodiment

[0035] (Eu 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 The preparation method is as example 1. .

[0036] xwt%Bi 2 o 3 -(100-x)wt%(Eu 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 The preparation is as in example 2-8.

example 1

[0038] in Eu 2 o 3 , Nb 2 o 5 and TiO 2 As a raw material, according to the chemical formula (Eu 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 Perform batching, wet ball milling for 4 hours, dry at 50°C, pre-calcine at 1200°C for 2 hours, and grind to obtain (Eu 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 The ceramic powder is then molded and sintered at 1400°C for 2 hours (Eu 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 Ceramic, tested by silver.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com